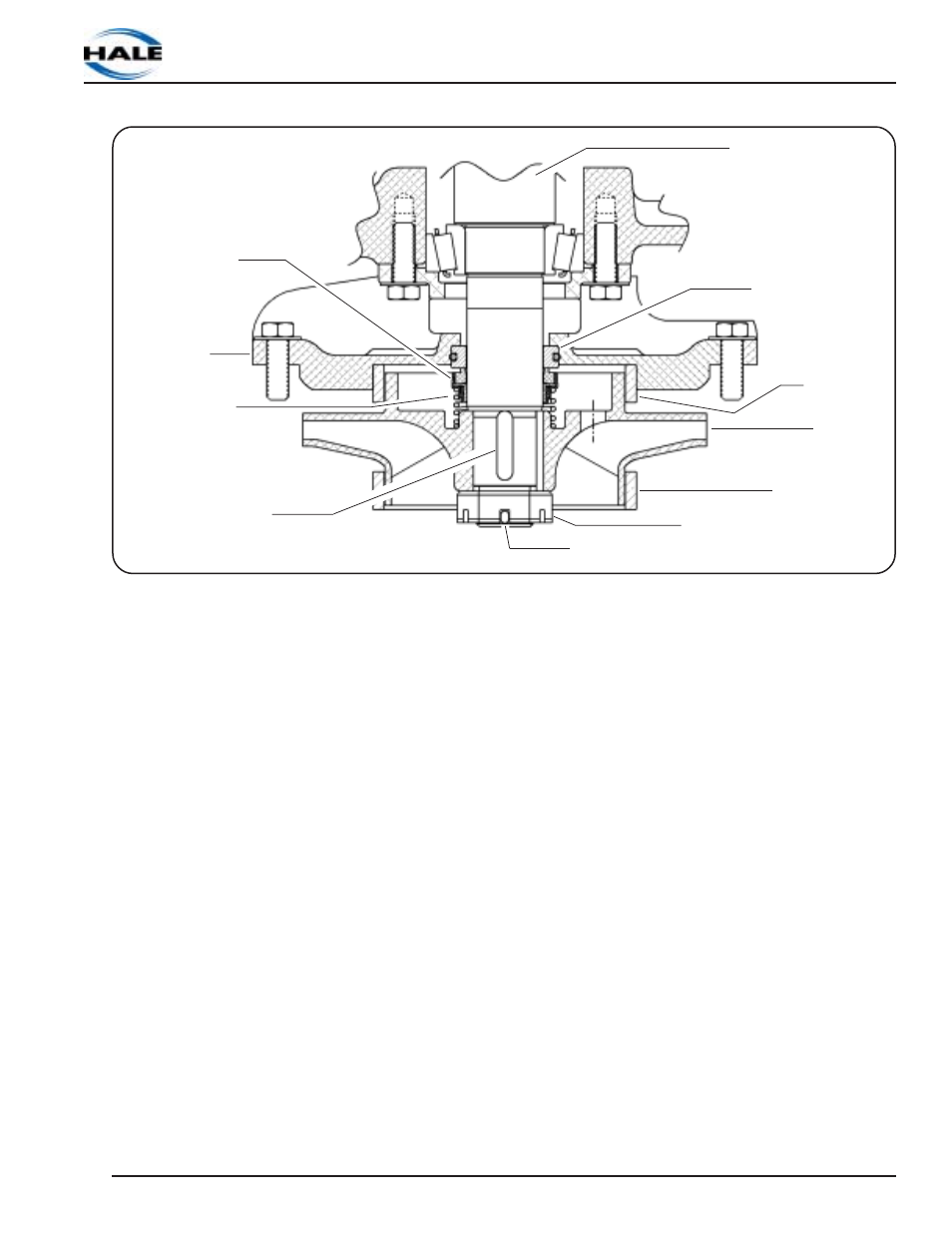

Figure 16: impeller / mechanical seal assembly, Impeller disassembly, Inspection – Hale 4DK Series User Manual

Page 33

Manual p/n: 029-0020-79-0

33

4DK Series Pumps

Impeller Disassembly

See Figure 16: "Impeller/Mechanical Seal

Assembly."

1. Remove the pump body per preceding

section.

2. Tap out the spring pin that locks the impel-

ler nut to the pump shaft.

3. While holding the impeller with a strap

wrench, remove the impeller nut.

4. Slide impeller from the pump shaft, then

remove the impeller shaft key.

Inspection

See Figure 16: "Impeller/Mechanical Seal

Assembly."

Impeller Hub

Inspect the impeller hub(s) for signs of

wear per dimensions listed below. Re-

place impeller if hub is worn or damaged

beyond repair.

❑

New impeller hub diameter:

4.752 to 4.754" (120,701-120,752mm)

❑

Wear limits:

4.747 to 4.754" (120,574-120,752mm)

Clearance Ring

See Figure 16: "Impeller/Mechanical Seal

Assembly."

Inspect clearance ring for signs of wear.

Measure the inside diameter of the clear-

ance ring while it is pressed into the pump

head.

❑

New clearance ring diameter (pressed):

4.770" to 4.777" (121.2-121.3mm)

Figure 16: Impeller / Mechanical Seal Assembly

Spring Pin

Impeller Nut

Clearance

Ring

Impeller

Mechanical

Seal

Mechanical

Seal

Seal Spring

Pump Shaft

Pump Head

Shaft Key

Clearance

Ring