Bryant DURAPACK 558F User Manual

Page 22

—

22

—

VI. STEP 6 — ADJUST FACTORY-INSTALLED OPTIONS

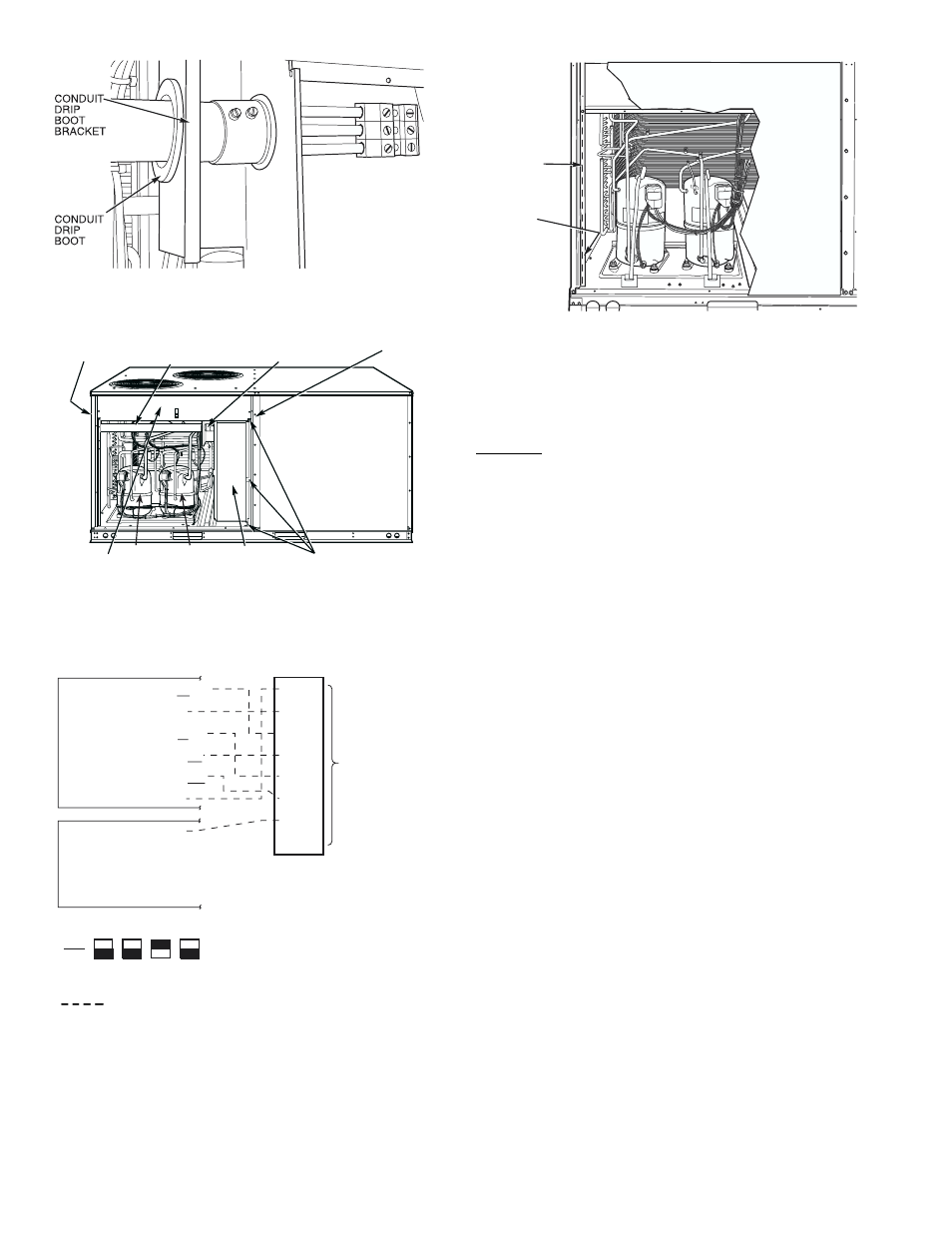

A. Manual Outdoor-Air Damper

The outdoor-air hood and screen are attached to the basepan

at the bottom of the unit for shipping.

Assembly:

1. Determine quantity of ventilation required for build-

ing. Record amount for use in Step 8.

2. Remove filter access panel by raising panel and

swinging panel outward. Panel is now disengaged

from track and can be removed. No tools are required

to remove the filter access panel. Remove outdoor-air

opening panel. Save panels and screws. See Fig. 13.

3. Separate hood and screen from basepan by removing

the screws and brackets securing them. Save all

screws and discard brackets.

4. Replace outdoor air opening panel.

5. Place hood on front of outdoor air opening panel. See

Fig. 14 for hood details. Secure top of hood with the

6 screws removed in Step 3. See Fig. 15.

6. Remove and save 8 screws (4 on each side) from sides

of the manual outdoor-air damper.

7. Align screw holes on hood with screw holes on side of

manual outdoor-air damper. See Fig. 14 and 15.

Secure hood with 8 screws from Step 6.

8. Adjust minimum position setting of the damper blade

by adjusting the manual outdoor-air adjustment

screws on the front of the damper blade. See Fig. 13.

Slide blade vertically until it is in the appropriate

position determined by Fig. 16. Tighten screws.

9. Remove and save screws currently on sides of hood.

Insert screen. Secure screen to hood using the screws.

See Fig. 15.

10. Replace filter access panel. Ensure filter access panel

slides along the tracks and is securely engaged.

B. Convenience Outlet

An optional convenience outlet provides power for rooftop

use. For maintenance personnel safety, the convenience out-

let power is off when the unit disconnect is off. Adjacent unit

outlets may be used for service tools. An optional “Hot Out-

let” is available from the factory as a special order item.

MAIN

CONTROL

BOX

BOX

SINGLE

POINT BOX

MOUNTING SCREW

DISCONNECT

MOUNTING

LOCATION

EMT OR RIGID

CONDUIT

(FIELD SUPPLIED)

BRACKET AND

CONDUIT DRIP

BOOT

CENTER

POST

COM-

PRESSOR

NO. 1

SINGLE

POINT

COM-

PRESSOR

NO. 2

Fig. 9 — Conduit Installation

LEGEND

EMT — Electro-Metallic Tubing

Fig. 10 — Typical Component Location

WIRE

CONNECTIONS

TO

LOW-VOLTAGE

SECTION

COOL STAGE 1

FAN

HEAT STAGE 1

COOL STAGE 2

HEAT STAGE 2

24 VAC HOT

24 VAC COM

N/A

OUTDOOR AIR

SENSOR

Y1/W2

G

W/W1

Y/Y2

O/W2

R

C

S1

S2

THERMOSTAT DIPSWITCH SETTINGS

R

G

Y1

Y2

W1

W2

C

IPD/X

ON

OFF

A

B

C

D

LEGEND

NOTE: Underlined letter indicates active thermostat output when con-

figured for A/C operation.

Fig. 11 — Low-Voltage Connections With or

Without Economizer or Two-Position Damper

Field Wiring

RACEWAY

HOLE IN

END PANEL

(HIDDEN)

Fig. 12 — Field Control Wiring Raceway