Page 22, Problem: water not hot enough – Bunn Dual TF User Manual

Page 22

Page 22

YES

YES

YES

YES

NO

NO

NO

NO

YES

NO

NO

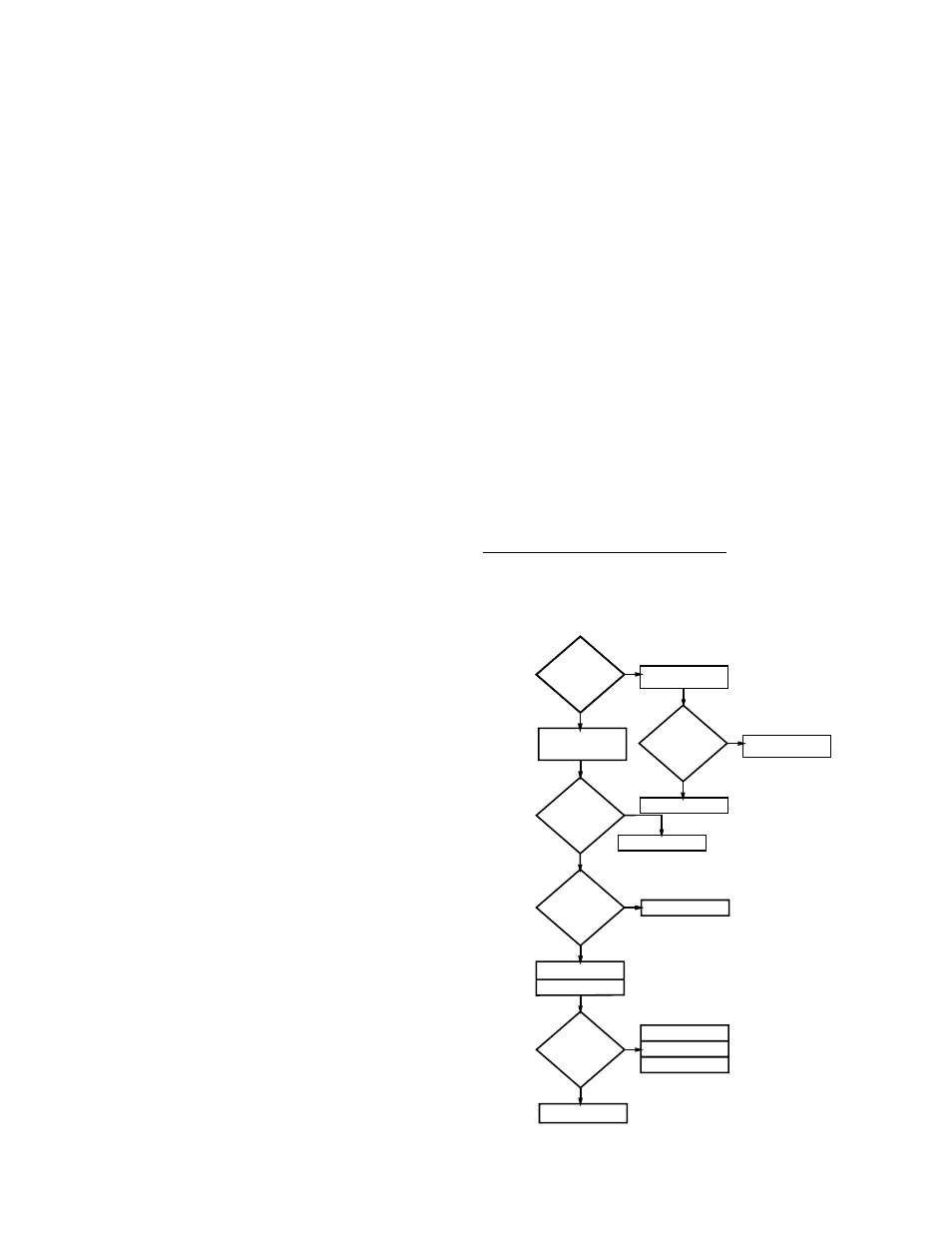

MEASURE VOLTAGE

AT TANK HEATER (5)

VOLTAGE PRESENT

REPLACE TANK

HEATER (5)

LIMIT THERMOSTAT (6)

OK

?

REPLACE LIMIT

THERMOSTAT (6)

REPLACE CONTROL

ASSEMBLY (1)

MEASURE VOLTAGE

AT TANK HEATER (5)

VOLTAGE PRESENT

REPLACE TRIAC (17)

CHECK FOR SPLIT

TANK HEATER (5)

REINSTALL ORIGINAL

CONTROL ASSEMBLY (1)

RECHECK WATER

TEMPERATURE

LED ON CONSTANTLY

TURN TEMPERATURE

ADJUSTING SCREW (16)

CLOCKWISE CONTINUOUSLY

LED ON

?

REPLACE CONTROL

ASSEMBLY (1)

ADJUST FOR CORRECT

WATER TEMPERARURE

3. Disconnect brewer from the power source.

If voltage was present as described, proceed to #4.

If voltage was not present as described, refer to the

wiring diagrams and check the brewer wiring harness.

4. Remove the pink wire from terminal 5 of the

electronic control assembly (1).

5. Check the voltage across terminals 1 & 4 of the

electronic control assembly (1) with a voltmeter.

Connect brewer to the power source. The indica-

tion must be:

a.) 208 volts ac for three wire 120/208 volt mod-

els and 240 volts ac for three wire 120/240 volt

models after a delay of approximately 1 sec-

ond.

b.) 200 to 240 volts ac for two wire 200 or 240 volt

models after a delay of approximately 1 sec-

ond.

6. Disconnect the brewer from the power source.

If voltage was present as described, the liquid level

control system is operating properly, proceed to #7.

If voltage was not present as described, replace the

electronic control assembly (1) and temperature sen-

sor (8) in the tank lid.

NOTE - each electronic control assembly is calibrated

to a temperature sensor. Both components MUST be

replaced as a set.

7. Reconnect the pink wire to terminal 5 of the

electronic control assembly (1).

8. Remove the liquid level probe (7) from the tank lid,

and inspect it for mineral deposits. Replace it if

necessary. Keep the exposed ends of the probe

away from any metal surface of the brewer.

9. Check the voltage across terminals 1 & 4 of the

electronic control assembly (1) with a voltmeter.

Connect the brewer to the power source. The

indication must be:

a.) 208 volts ac for three wire 120/208 volt mod-

els and 240 volts ac for three wire 120/240 volt

models after a delay of approximately 1 sec-

ond.

b.) 200 to 240 volts ac for two wire 208 or 240 volt

models after a delay of approximately 1 sec-

ond.

10. Touch the screw head end of the probe to the

brewer housing. The indication must be 0.

11. Move the probe away from the brewer housing.

The indication must again be:

a.) 208 volts ac for three wire 120/208 volt mod-

els and 240 volts ac for three wire 120/240 volt

models after a delay of approximately 1 sec-

ond.

b.) 200 to 240 volts ac for two wire 200 or 240 volt

models after a delay of approximately 1 sec-

ond.

12. Disconnect the brewer from the power source.

If voltage was present as described, reinstall the

probe, the sensing function of the system is operating

properly.

If voltage was not present as described, check the pink

probe wire and the green ground wire for continuity

and/or replace the probe.

Temperature Control Flow Charts

SERVICE (cont.)

ELECTRONIC CONTROL ASSEMBLY (cont.)

P810

PROBLEM:

WATER NOT HOT ENOUGH

27124 050800