Start-up, Service – Bryant Air Handling Units 524J User Manual

Page 20

20

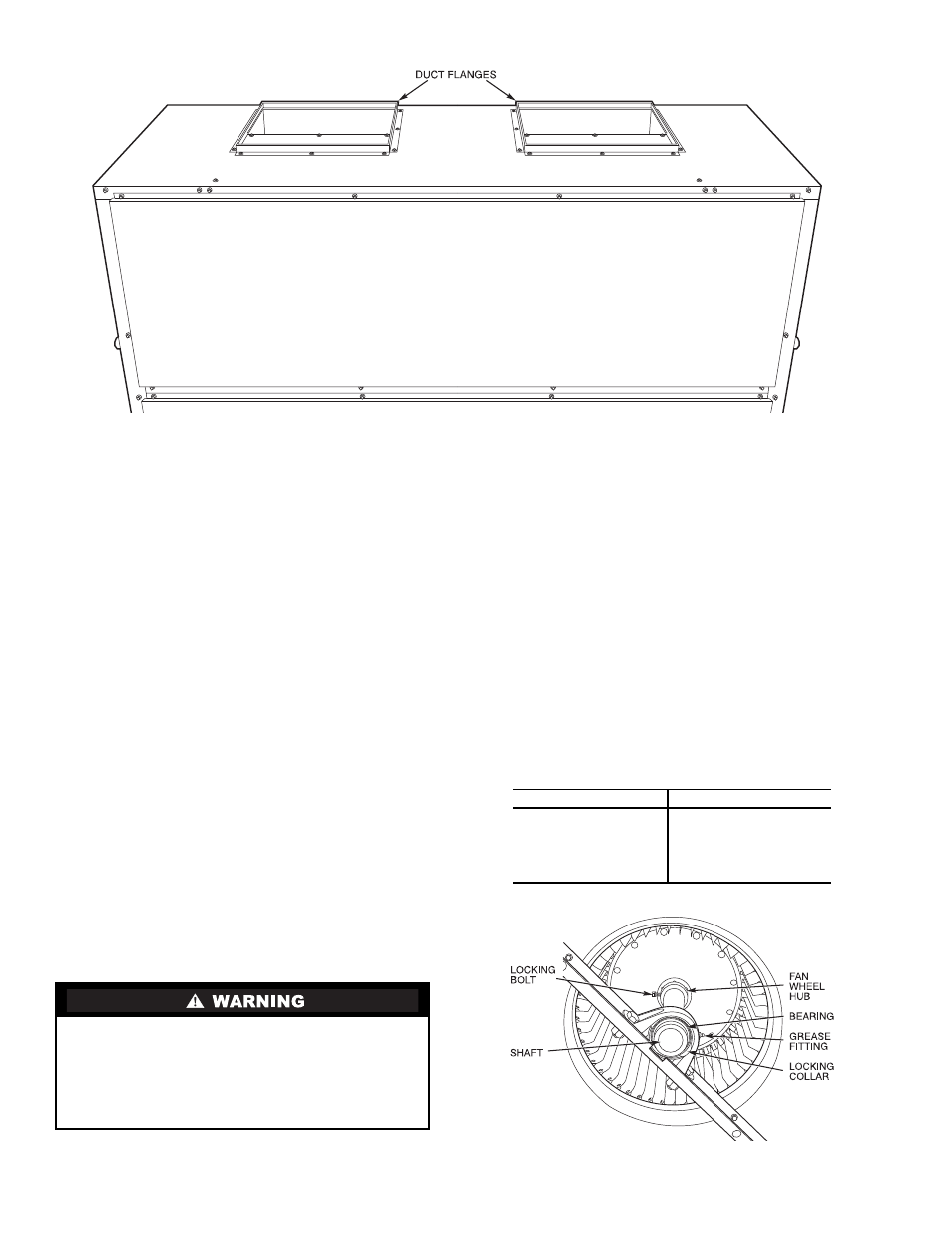

Fig. 18 — Duct Flange Installation

START-UP

Before starting unit, check the following and correct as neces-

sary:

• Is unit solidly supported?

• Is fan adjusted for speed and pulley alignment?

• Are pulleys, motor, and bearings securely mounted?

• Are there any loose parts that will rattle or vibrate?

• Is condensate drain pan pitched for correct drainage?

• Are coil baffle plates tight against coil to prevent air

bypass?

• Are all panels securely fastened?

• Are all electrical connections correct and tight?

Also refer to condensing unit instructions before starting a split

system. A split system start-up checklist is provided at the end

of these instructions.

SERVICE

Inspection and maintenance should be performed at regular in-

tervals and should include the following:

• Complete cleaning of cabinet, fan wheel, cooling coil,

condensate pan and drain, heating coils, and return-air

grille (if present).

• Inspection of panels and sealing of unit against air

leakage.

• Adjustment of fan motor, belt, bearings, and wheels.

• Cleaning or replacement of filters.

• Testing for cooling/heating system leaks.

• Checking of all electrical connections.

Most unit service can be performed by removing one or both of

the unit’s side panels. Coil cleaning or removal or insulation

cleaning may require removal of a rear, top, or bottom panel,

depending on the unit’s orientation. When service is

completed, replace unit panels.

Panels —

Panels are fastened to unit frame with sheet metal

screws. Fan and coil compartment must be sealed tightly after

service to prevent air from bypassing the cooling coil.

Fan Motor Lubrication —

Fan motor supplied with

unit is permanently lubricated and requires no further

lubrication.

Fan Shaft Bearings —

Bearings on size 07-12 units are

sealed, permanently lubricated bearings that require no further

lubrication. Size 14-16 units have pillow-block bearings

(Fig. 20) that must be lubricated with suitable bearing grease

approximately every 3 months. See Table 7 for suitable

lubricants.

Table 7 — Lubricant Data

*Preferred lubricant, contains rust and oxidation inhibitors.

Fig. 19 — Fan Shaft, Bearings, and Fan Wheel (Typical)

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal injury

or death.

Before performing service or maintenance operations on

unit, always turn off main power switch to unit and install

lockout tag. Unit may have more than one power switch.

MANUFACTURER

LUBRICANT

Mobil

Mobilplex EP No. 2

Sunoco

Prestige 42

Texaco

Multifak 2

Texaco

Regal AFB-2*