Power supply and wiring, In. ring terminal – Bryant Air Handling Units 524J User Manual

Page 16

16

Power Supply and Wiring —

Check the unit data

plate to ensure that available power supply matches electrical

characteristics of the unit. Provide a disconnect switch with an

integrated lock-out feature of size required to provide adequate

fan motor starting current. See Tables 4-6 for unit electrical

data.

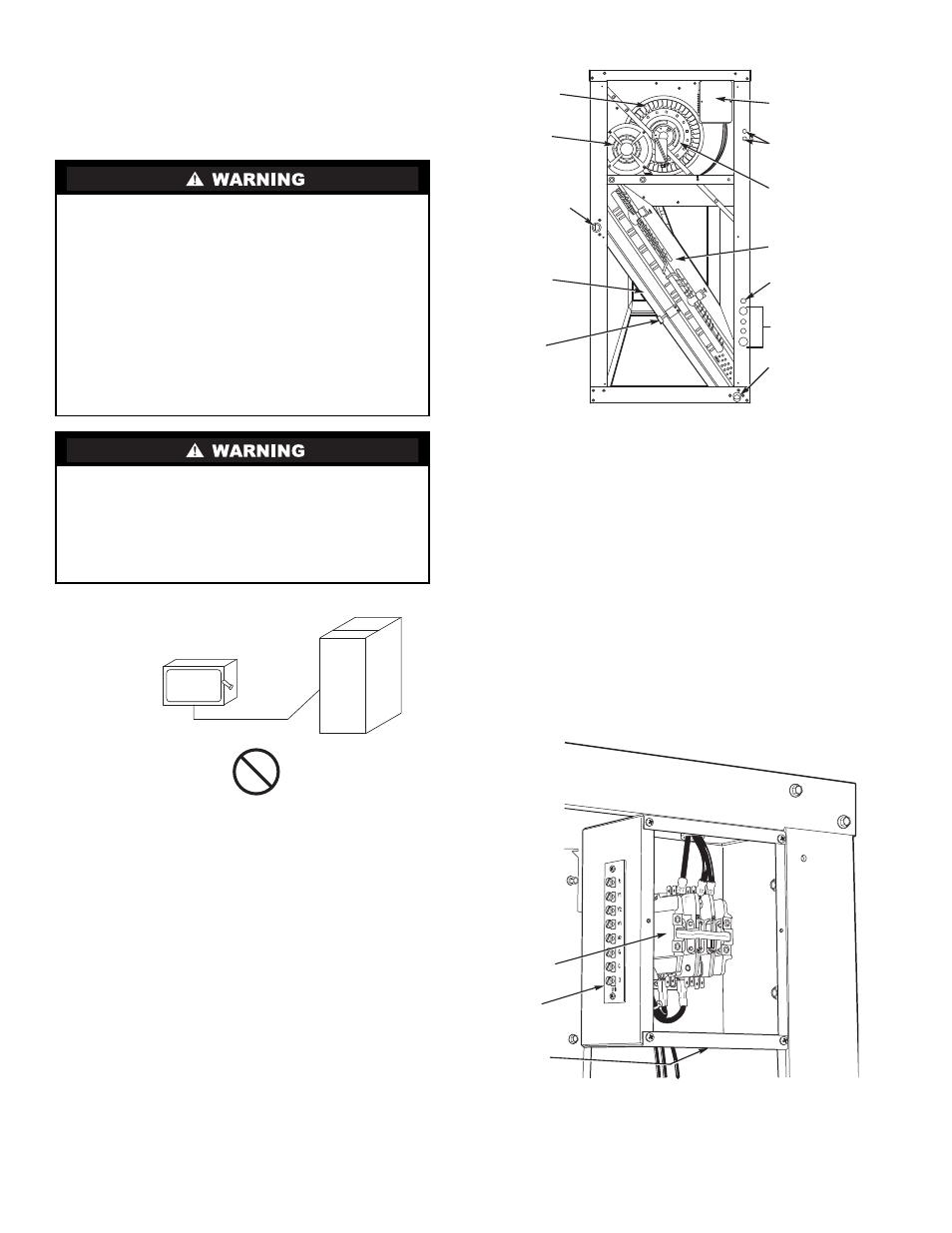

Fig. 13 — Disconnect Switch and Unit

Install disconnect switch and power wiring in accordance with

all applicable local codes. See Fig. 14-16 and the unit label

diagram. For units with motor sizes less than 5 Hp (3.7 kW),

connect power wiring to unit with no. 10 ring terminal. For

units with motor sizes of 5 Hp (3.7 kW) or more, connect

power wiring with

1

/

4

-in. ring terminal.

Fig. 14 — Wiring and Service Access

(Side Panel Removed)

The 524J size 07-16 units that have motors wired for 460-v,

3-ph, 60 Hz operation can be field-converted to 208/230-v,

3-ph, 60 Hz operation. Rewire the motor according to the

diagram plate on the motor. After reconfiguring the motor,

mark the motor specifying 208-v or 230-v operation replacing

the 460-v sticker information on the units’ corner post.

Fan motors are factory-installed on all units. Indoor-fan

contactors are located in the fan contactor box behind the side

access panel (see Fig. 14 and 15). Wire the thermostat to the

24-v control circuit terminal block located in the side of the fan

contactor control box, according to Fig. 16 or the unit label

diagram. If the air handler is part of a split system, complete the

wiring from the condensing unit to the thermostat shown in

Fig. 16.

Fig. 15 — Fan Contactor Box and Terminal Block

(Cover Removed) (Typical)

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Do not use gas piping as an electrical ground. Unit cabinet

must have an uninterrupted, unbroken electrical ground to

minimize the possibility of personal injury if an electrical

fault should occur. This ground may consist of electrical

wire connected to unit ground lug in control compartment,

or conduit approved for electrical ground when installed in

accordance with NEC (National Electrical Code); ANSI/

NFPA 70, latest edition (in Canada, Canadian Electrical

Code CSA [Canadian Standards Association] C22.1), and

local electrical codes.

FIRE HAZARD

Failure to follow this warning could result in intermittent

operation or performance satisfaction.

Do not connect aluminum wire between disconnect switch

and condensing unit. Use only copper wire.

(See Fig. 13.)

COPPER

WIRE ONLY

ELECTRIC

DISCONNECT

SWITCH

ALUMINUM

WIRE

FILTER

ELEMENTS

FILTER

RETAINER

CLIP

FAN SCROLL

CONDENSATE

DRAIN

CONNECTION

(HORIZONTAL)

MOTOR

AND DRIVE

FAN

CONTACTOR

BOX

WIRE

ACCESS

COIL

FAN DRIVE

PULLEY

TXV BULB

ACCESS

REFRIGERANT/

CHILLED WATER

PIPING ACCESS

CONDENSATE

DRAIN

CONNNECTION

(VERTICAL)

LEGEND

TXV — Thermostatic Expansion Valve

2 3

2 2

2 1

1 3

1 2

1 1

1

0

5

°

C

6

00

V

R

J

A

W

FAN

CONTACTOR

24V

TERMINAL

BLOCK

POWER

WIRING

KNOCKOUT