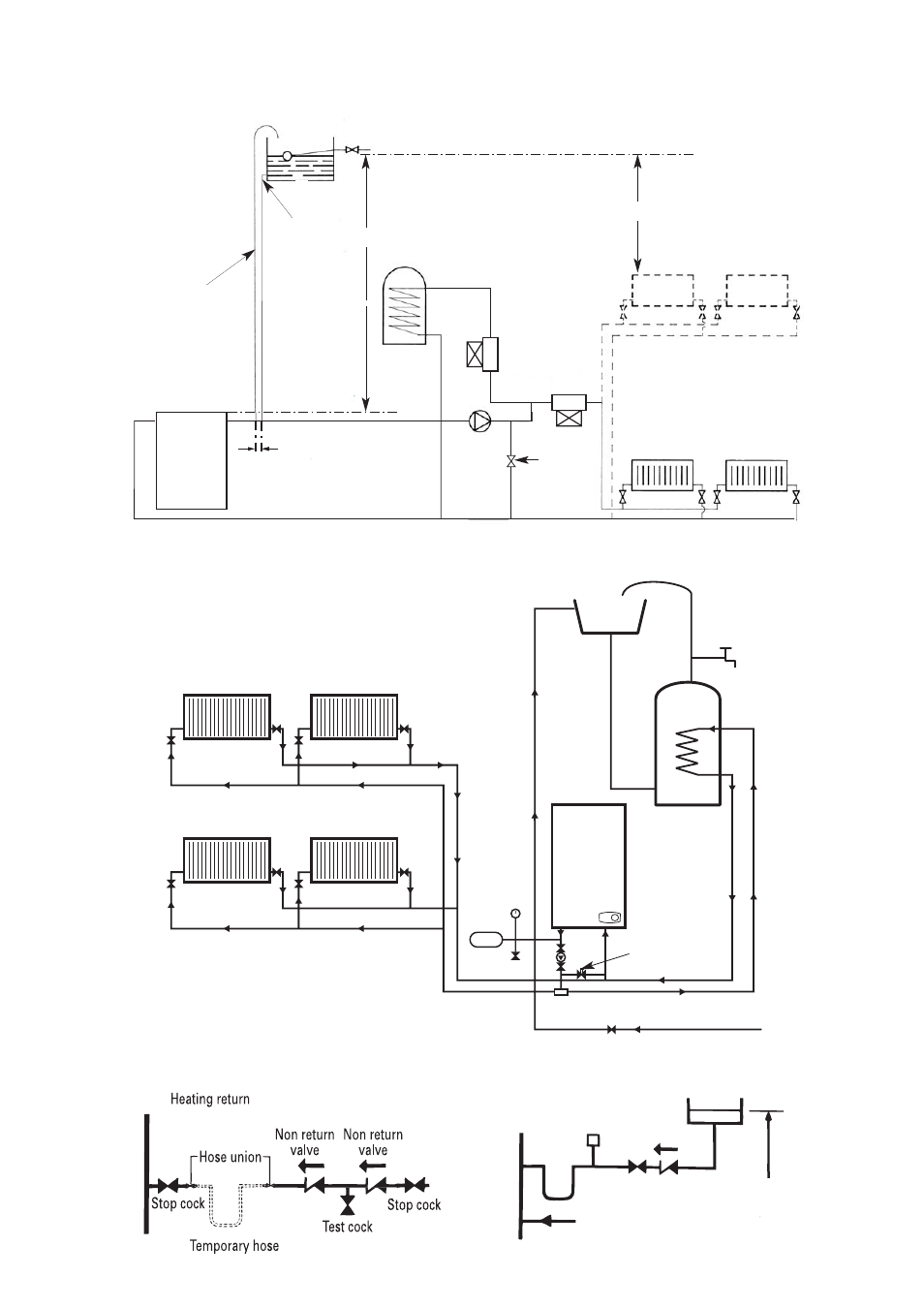

Fig. 7. fully pumped sealed system, Fig. 6. system layout if using honeywell 's' plan, Fig. 8. sealed system filling and make-up – Bosch 14/19CBI User Manual

Page 9

Heating return

Non return

valve

Non return

valve

Hose union

Test cock

Temporary hose

Stop cock

Auto

air vent

Heating return

Stop

cock

Fill point

Non return

valve

Make up

vessel

1200mm (48 in)

above the highest

point of the system.

9

Note:

A drain cock

should be fitted

at the lowest

point of the

heating circuit

and beneath

the appliance

Fig. 7. Fully pumped sealed system.

RV

LV

LV

RV

RV

RV

LV

LV

INDIRECT

CYLINDER

APPLIANCE

Heating R

eturn

Heating Flow

Cylinder R

eturn

Hot W

ater Flow

BS

Stop Valve Fixed Cylinder Type or sealed systems - Approved connection

Mains Cold Water

Radiator Valve - Flow RV

Lockshield Valve - Return LV

Expansion

Vessel

For system

wiring

please refer to

Fig. 10. and the

controls

manufacturers

details.

Bypass

balancing valve or

bathroom

radiatior with two

lockshield valves

Pressure

Gauge

Relief

Valve

Fig. 8. Sealed system filling and make-up.

Primary

cold feed

(15mm min.)

Heating vent

(22mm min.)

Feed and

Vent Cistern

Diverting

valves

Boiler

Pump

Radiator

S.H. – Minimum static head 1.2m

measured from the highest point in the

heating system (top surface of the appliance

or highest point in the heating system) to the

water level in the feed and expansion tank

N.B. A drain cock should be

installed at the lowest point of

the heating circuit

Domestic hot

water cylinder

S.H.

S.H.

150mm max

Fig. 6. System layout if using Honeywell 'S' plan

For system wiring please refer to

Fig. 10. and the controls

manufacturers details.

Bypass or

uncontrolled

radiator