Step 7 - make electrical connections, Warning, Step 7 —make electrical connections – Bryant 581C024--060 User Manual

Page 8

8

C06114

Fig. 10

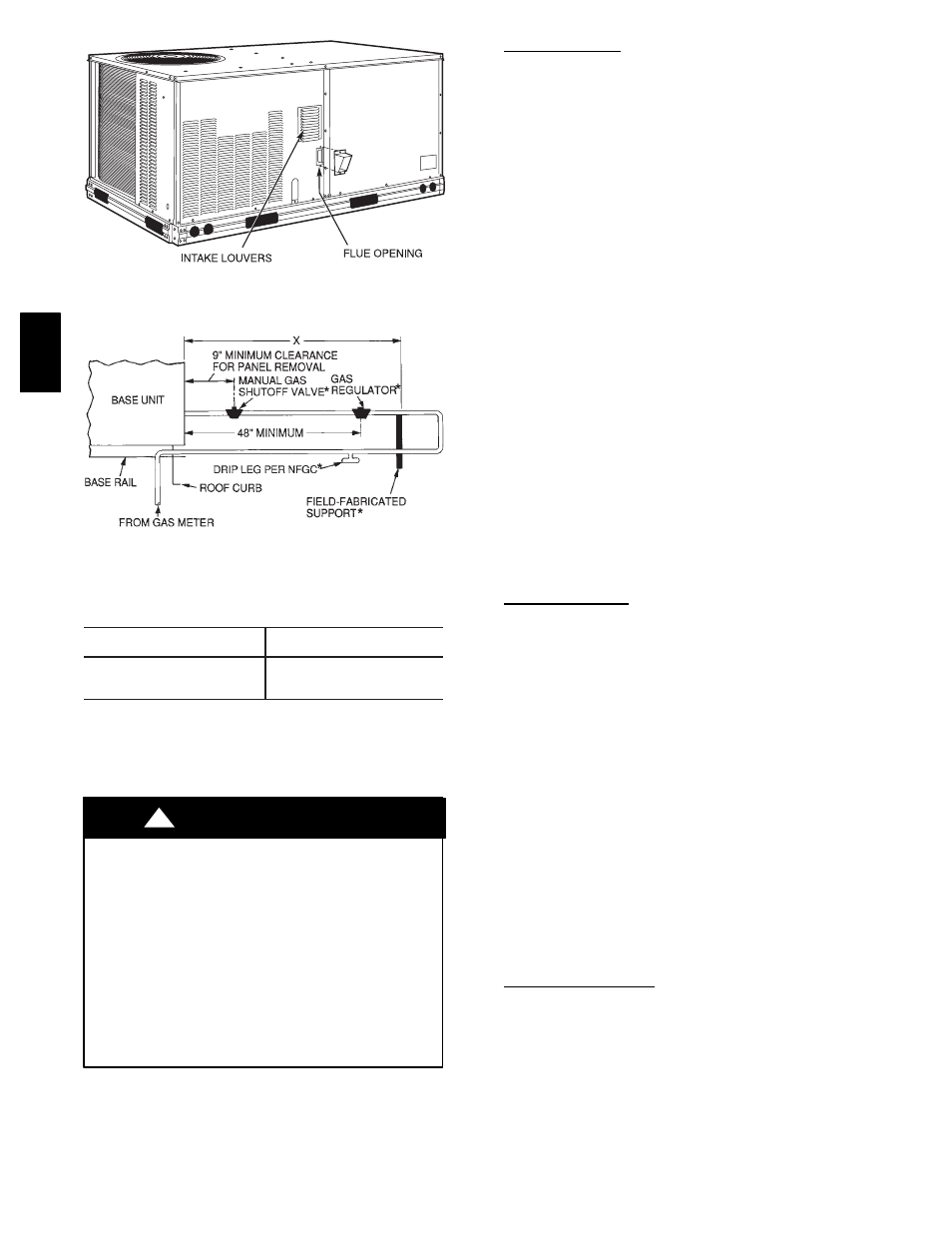

--- Flue Hood Details

LEGEND

*Field supplied.

NOTE: Follow all local codes.

SPACING OF SUPPORTS

NFGC — National Fuel Gas Code

STEEL PIPE

NOMINAL DIAMETER (in.)

SPACING OF SUPPORTS

X DIMENSION (ft)

1

/

2

3

/

4

or 1

1

1

/

4

or larger

6

8

10

C06115

Fig. 11

--- Gas Piping Guide (With Accessory

Thru--the--Curb Service Connections)

Step 7

—Make Electrical Connections

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Unit cabinet must have an uninterrupted, unbroken

electrical ground to minimize the possibility of personal

injury if an electrical fault should occur. This ground

may consist of electrical wire connected to unit ground

lug in control compartment, or conduit approved for

electrical ground when installed in accordance with

NEC (National Electrical Code), ANSI/NFPA (National

Fire Protection Association), latest edition, and local

electrical codes. Do not use gas piping as an electrical

ground.

!

WARNING

Field Power Supply

All units except 208/230-v units are factory wired for the voltage

shown on the nameplate. If the 208/230-v unit is to be connected

to a 208-v power supply, the transformer must be rewired by

moving the black wire from the 230-v terminal on the

transformer and connecting it to the 200-v terminal from the

transformer.

Refer to unit label diagram for additional information. Pigtails

are provided for field service. Use factory-supplied splices or UL

(Underwriters’ Laboratories) approved copper connector.

When installing units, provide a disconnect per NEC.

All field wiring must comply with NEC and local

requirements.

Install conduit through side panel openings indicated in Fig. 8.

Route power lines through connector to terminal connections as

shown in Fig. 12.

Voltage to compressor terminals during operation must be within

voltage range indicated on unit nameplate (also see Tables 3 and

4). On 3-phase units, voltages between phases must be balanced

within 2% and the current within 10%. Use the formula shown in

Tables 3 and 4, Note 3 to determine the percent voltage

imbalance. Operation on improper line voltage or excessive phase

imbalance constitutes abuse and may cause damage to electrical

components. Such operation would invalidate any applicable

Bryant warranty.

NOTE: If accessory thru-the-bottom connections and roof curb

are used, refer to the Thru-the-Bottom Accessory Installation

Instructions for information on power wiring and gas connection

piping. The power wiring, control wiring and gas piping can be

routed through field-drilled holes in the basepan. The basepan is

specially designed and dimpled for drilling the access connection

holes. (See Fig. 2.)

Field Control Wiring

Install a Bryant-approved accessory thermostat assembly

according to installation instructions included with the accessory.

Locate thermostat assembly on a solid wall in the conditioned

space to sense average temperature in accordance with thermostat

installation instructions.

Route thermostat cable or equivalent single leads of colored wire

from subbase terminals through connector on unit to low-voltage

connections (shown in Fig. 13 and 14).

Connect thermostat wires to matching screw terminals of

low-voltage connection board. (See Fig. 13 and 14.)

NOTE: For wire runs up to 50 ft, use no. 18 AWG (American

Wire Gauge) insulated wire (35_C minimum). For 50 to 75 ft, use

no. 16 AWG insulated wire (35_C minimum). For over 75 ft, use

no. 14 AWG insulated wire (35_C minimum). All wire larger

than no. 18 AWG cannot be directly connected to the thermostat

and will require a junction box and splice at the thermostat.

Pass the control wires through the hole provided in the

corner

post; then feed wires through the raceway built into the corner

post to the 24-v barrier located on the left side of the control box.

(See Fig. 15). The raceway provides the UL required clearance

between high and low-voltage wiring.

Heat Anticipator Settings

Set heat anticipator settings at 0.14 amp for first stage and 0.14

for second stage heating, when available.

581B

,C