Bryant 581C024--060 User Manual

Page 44

44

Heating -- Units With Economi$er IV

When the room temperature calls for heat, the heating controls are

energized as described in the Heating, Units Without Economizer

section. During the occupied mode, whenever the indoor fan

contactor is energized, the economizer damper moves to the

minimum position.

Units With Perfect Humidity™ Adaptive

Dehumidification System

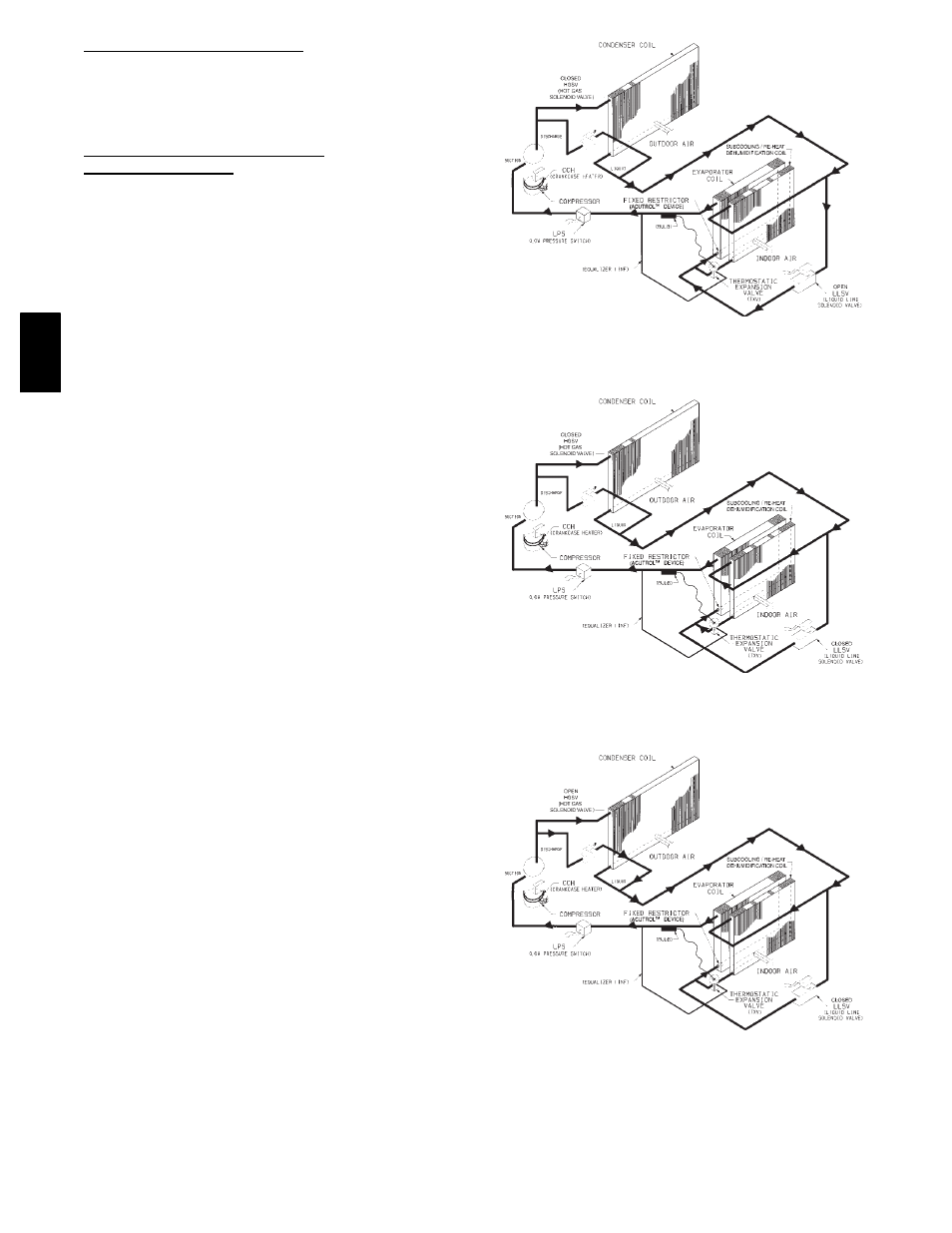

Normal Design Operation

When the rooftop operates under the normal sequence of

operation, the compressors will cycle to maintain indoor

conditions. (See Fig. 44.)

The Perfect Humidity adaptive dehumidification system includes

a factory-installed Motormaster® low ambient control to keep the

head and suction pressure high, allowing normal design cooling

mode operation down to 0°F.

Subcooling Mode

When subcooling mode is initiated, this will energize (close) the

liquid line solenoid valve (LLSV) forcing the hot liquid

refrigerant to enter into the subcooling coil. (See Fig. 45.)

As the hot liquid refrigerant passes through the subcooling/ reheat

dehumidification coil, it is exposed to the cold supply airflow

coming through the evaporator coil. The liquid is further

subcooled to a temperature approaching the evaporator

leaving-air temperature. The liquid then enters a thermostatic

expansion valve (TXV) where the liquid drops to a lower

pressure. The TXV does not have a pressure drop great enough to

change the liquid to a 2-phase fluid, so the liquid then enters the

Acutrol™ device at the evaporator coil.

The liquid enters the evaporator coil at a temperature lower than

in standard cooling operation. This lower temperature increases

the latent capacity of the rooftop unit. The refrigerant passes

through the evaporator and is turned into a vapor. The air passing

over the evaporator coil will become colder than during normal

operation. However, as this same air passes over the subcooling

coil, it will be slightly warmed, partially reheating the air.

Subcooling mode operates only when the outside air

temperature is warmer than 40_F. A factory-installed temperature

switch located in the condenser section will lock out subcooling

mode when the outside temperature is cooler than 40_F.

The scroll compressors are equipped with crankcase heaters to

provide protection for the compressors due to the additional

refrigerant charge required by the subcooling/reheat coil.

When in subcooling mode, there is a slight decrease in system

total gross capacity (5% less), a lower gross sensible capacity

(20% less), and a greatly increased latent capacity (up to 40%

more).

Hot Gas Reheat Mode

When the humidity levels in the space require humidity control, a

hot gas solenoid valve (specific to hot gas reheat mode only) will

open to bypass a portion of hot gas refrigerant around the

condenser coil. (See Fig. 46.)

This hot gas will mix with liquid refrigerant leaving the

condenser

coil

and

flow

to

the

subcooling/reheat

dehumidification coil. Now the conditioned air coming off the

evaporator will be cooled and dehumidified, but will be warmed

to neutral conditions (72_F to 75_F) by the subcooling/reheat

dehumidification coil.

C06135

Fig. 44

--- Perfect Humidityt Normal

Design Cooling Operation

C06136

Fig. 45

--- Perfect Humidity Subcooling

Mode Operation

C06137

Fig. 46

--- Perfect Humidity Hot Gas

Reheat Mode Operation

See Table 37 for the Perfect Humidity adaptive dehumidification

system sequence of operation.

581B

,C