Step 5 - install flue hood, Step 6 - install gas piping, Step 5 —install flue hood – Bryant 581C024--060 User Manual

Page 4: Step 6 —install gas piping

4

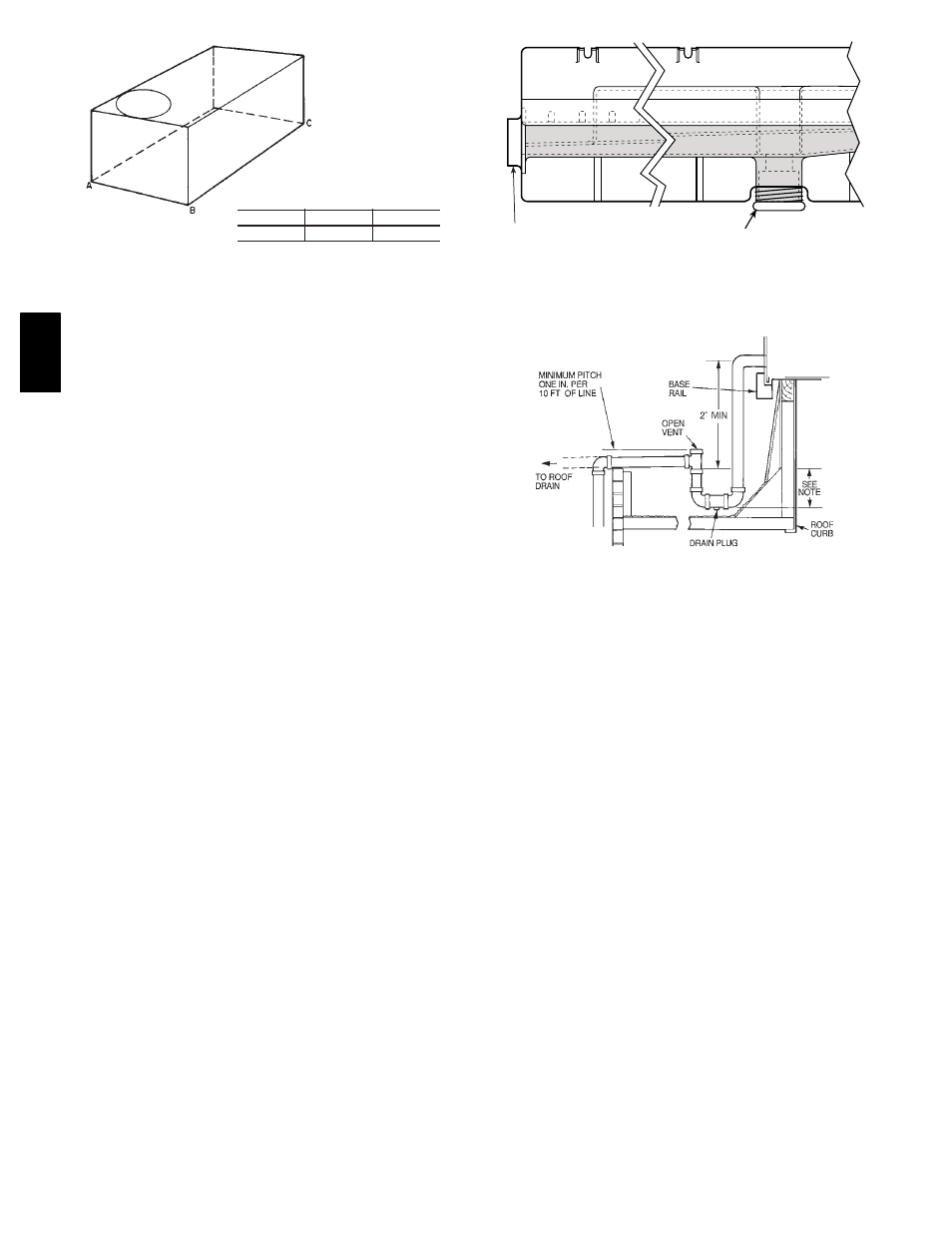

MAXIMUM ALLOWABLE

DIFFERENCE (in.)

A-B

B-C

A-C

0.5

1.0

1.0

C06110

Fig. 3

--- Unit Leveling Tolerances

Be sure that unit is installed such that snow will not block the

combustion intake or flue outlet.

Unit may be installed directly on wood flooring or on Class A, B,

or C roof-covering material when roof curb is used.

Although unit is weatherproof, guard against water from higher

level runoff and overhangs.

Locate mechanical draft system flue assembly at least 48 in. from

an adjacent building or combustible material. When unit is

located adjacent to public walkways, flue assembly must be at

least 7 ft above grade.

NOTE: When unit is equipped with an accessory flue discharge

deflector, allowable clearance is 18 inches.

Flue gas can deteriorate building materials. Orient unit such that

flue gas will not affect building materials.

Adequate combustion-air space must be provided for proper

operation of this equipment. Be sure that installation complies

with all local codes and Section 5.3, Air for Combustion and

Ventilation, NFGC (National Fuel Gas Code), ANSI (American

National Standards Institute) Z223.1-1984 and addendum

Z223.1a-1987. In Canada, installation must be in accordance with

the CAN1.B149.1 and CAN1.B149.2 installation codes for gas

burning appliances.

Flue vent discharge must have a minimum horizontal clearance of

4 ft from electric and gas meters, gas regulators, and gas relief

equipment.

After unit is in position, remove shipping materials and rigging

skids.

Step 5

—Install Flue Hood

Flue hood is shipped screwed to the burner compartment access

panel. Remove from shipping location and, using screws

provided, install flue hood in location shown in Fig. 8 and 9.

For units being installed in California Air Quality Management

Districts which require NOx emissions of 40 nanograms/joule or

less, a low NOx unit must be installed.

NOTE: Low NOx units are available for 2 to 5 ton units.

DRAIN PLUG

CONDENSATE PAN (SIDE VIEW)

HORIZONTAL

DRAIN OUTLET

NOTE: Drain plug is shown in factory-installed position.

C06003

Fig. 4

--- Condensate Drain Pan

NOTE: Trap should be deep enough to offset maximum unit static

difference. A 4-in. trap is recommended.

C06004

Fig. 5

--- Condensate Drain Piping Details

Step 6

—Install Gas Piping

Unit is equipped for use with type of gas shown on nameplate.

Refer to local

building codes, or in the absence of local codes,

to ANSI Z223.1-1984 and addendum Z223.1A-1987 entitled

National Fuel Gas Code. In Canada, installation must be in

accordance with the CAN1.B149.1

and CAN1.B149.2

installation codes for gas burning appliances.

For natural gas applications, gas pressure at unit gas connection

must not be less than 4 in. wg or greater than 13 in. wg while the

unit is operating. On 581B036--072 and 581C036--060 high-heat

units, the gas pressure at unit gas connection must not be less than

5 in. wg or greater than 13 in. wg while the unit is operating. For

propane applications, the gas pressure must not be less than 5 in.

wg or greater than 13 in. wg at the unit connection.

Size gas supply piping for 0.5 in. wg maximum pressure drop.

Do not use supply pipe smaller than unit gas connection.

581B

,C