Step 1 - provide unit support, Step 2 - field fabricate ductwork, Step 4 - rig and place unit – Bryant 581C024--060 User Manual

Page 2: Warning, Step 1 —provide unit support, Step 2 —field fabricate ductwork, Step 3 —install external trap for condensate drain, Step 4 —rig and place unit

2

C06108

Fig. 1

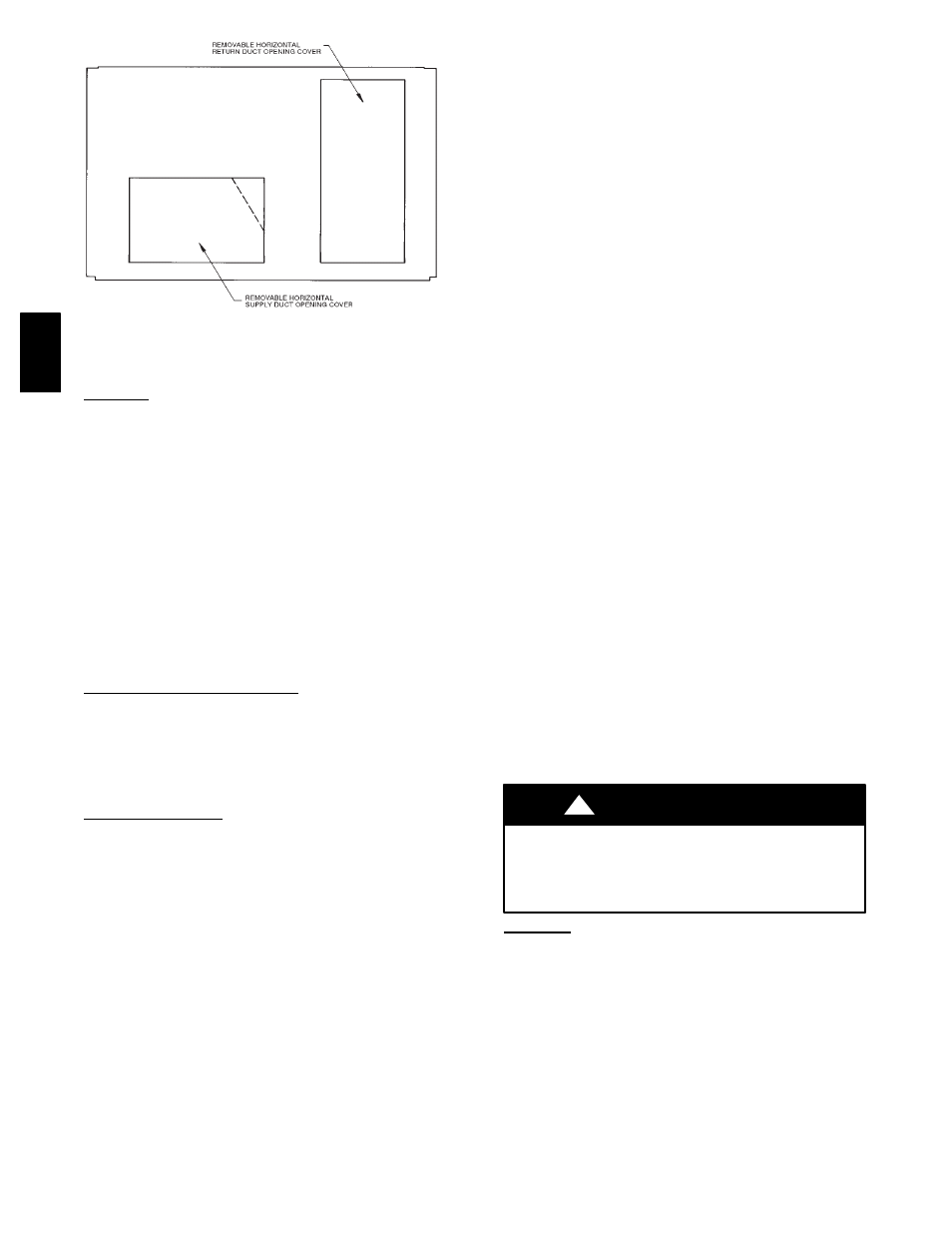

--- Horizontal Conversion Panels

Step 1

—Provide Unit Support

Roof Curb

Assemble and install accessory roof curb in accordance with

instructions shipped with curb. (See Fig. 2.) Install insulation,

cant strips, roofing felt, and counter flashing as shown. Ductwork

must be attached to curb, not to the unit. If electric control power

or gas service is to be routed through the basepan, attach the

accessory thru-the-bottom service connections to the basepan in

accordance with

the accessory

installation instructions.

Connections must be installed before unit is set on roof curb.

IMPORTANT: The gasketing of the unit to the roof curb is

critical for a watertight seal. Install gasket supplied with the roof

curb as shown in Fig. 2. Improperly applied gasket can result in

air leaks and poor unit performance.

Curb should be level. Unit leveling tolerances are shown in Fig.

3. This is necessary for unit drain to function properly. Refer to

Accessory Roof Curb Installation Instructions for additional

information as required.

Slab Mount (Horizontal Units Only)

Provide a level concrete slab that extends a minimum of 6 in.

beyond unit cabinet. Install a gravel apron in front of

condenser-coil air inlet to prevent grass and foliage from

obstructing airflow.

NOTE: Horizontal units may be installed on a roof curb if

required.

Alternate Unit Support

When the curb or adapter cannot be used, support unit with

sleeper rails using unit curb or adapter support area. If sleeper

rails cannot be used, support the long sides of the unit with a

minimum of 3 equally spaced 4-in. x 4-in. pads on each side.

Step 2

—Field Fabricate Ductwork

Secure all ducts to roof curb and building structure on vertical

discharge units. Do not connect ductwork to unit. For horizontal

applications, field-supplied isolation flanges should be attached to

horizontal discharge openings and all ductwork should be secured

to the flanges. Insulate and weatherproof all external ductwork,

joints, and roof openings with counter flashing and mastic in

accordance with applicable codes.

Ducts passing through an unconditioned space must be insulated

and covered with a vapor barrier.

If a plenum return is used on a vertical unit, the return should be

ducted through the roof deck to comply with applicable fire

codes.

A minimum clearance is not required around ductwork. Cabinet

return-air static pressure (a negative condition) shall not exceed

0.35 in. wg with economizer or 0.45 in. wg without economizer.

These units are designed for a minimum continuous return-air

temperature in heating of 50_F (dry bulb), or an intermittent

operation down to 45_F (dry bulb), such as when used with a

night setback thermostat.

To operate at lower return-air temperatures, a field-supplied

outdoor air temperature control must be used to initiate both

stages of heat when the temperature is below 45_F. Indoor

comfort may be compromised when these lower air temperatures

are used with insufficient heating temperature rise.

Step 3

—Install External Trap for Condensate

Drain

The unit’s

3

/

4

-in. condensate drain connections are located on the

bottom and side of the unit. Unit discharge connections do not

determine the use of drain connections; either drain connection

can be used with vertical or horizontal applications.

When using the standard side drain connection, ensure the plug

(Red) in the alternate bottom connection is tight before installing

the unit.

To use the bottom drain connection for a roof curb installation,

relocate the factory-installed plug (Red) from the bottom

connection to the side connection. The center drain plug looks

like a star connection, however it can be removed with a

1

/

2

-in.

socket drive extension. (See Fig. 4.) The piping for the

condensate drain and external trap can be completed after the unit

is in place.

All units must have an external trap for condensate drainage.

Install a trap 4-in. deep and protect against freeze-up. If drain line

is installed downstream from the external trap, pitch the line away

from the unit at 1 in. per 10 ft of run. Do not use a pipe size

smaller than the unit connection (

3

/

4

in.). (See Fig. 5.)

Step 4

—Rig and Place Unit

Inspect unit for transportation damage, and file any claim with

transportation agency. Keep unit upright and do not drop.

Spreader bars are not required if top crating is left on unit, and

rollers may be used to move unit across a roof. Level by using

unit frame as a reference. See Table 1 and 2 and Fig. 6 for

additional information. Operating weight is shown in Table 1 and

2 and Fig. 6.

Lifting holes are provided in base rails as shown in Fig. 8 and 9.

Refer to rigging instructions on unit.

PROPERTY DAMAGE HAZARD

Failure to follow this warning could result in personal

injury, death and property damage.

All panels must be in place when rigging and lifting.

!

WARNING

Positioning

Maintain clearance around and above unit to provide minimum

distance from combustible materials, proper airflow, and service

access. (See Fig. 7, 8 and 9.)

Position unit on roof curb so that the following clearances are

maintained:

1

/

4

in. clearance between the roof curb and the base

rail inside the front and rear, 0.0 in. clearance between the roof

curb and the base rail inside on the duct end of the unit. This will

result in the distance between the roof curb and the base rail

inside on the condenser end of the unit being approximately

equal to Fig. 2, section C-C.

Do not install unit in an indoor location. Do not locate unit air

inlets near exhaust vents or other sources of contaminated air.

581B

,C