Bryant Single Package Rooftop Electric Heating/Electric Cooling Unit 558D User Manual

Page 19

of cooling is satisfied, the compressor and OFM will be deen-

ergized. The damper position will be determined by the supply-

air temperature. When the first stage of cooling is satisfied,

there is a 30-second delay before the evaporator fan shuts

off. The damper then moves to the fully closed position. When

using a continous fan, the damper moves to the minimum

position. Additional information on economizer operation is

provided in the Ventilation Sequence section on page 27.

Cooling, Units With PARABLADE Economizer

When the outdoor-air is above the enthalpy control setting,

and the room thermostat calls for cooling, the compressor con-

tactor is energized to start the compressor and the outdoor

(condenser) fan motor. The indoor (evaporator) fan motor is

energized and the economizer damper moves to the mini-

mum position. After the room thermostat is satisfied the damper

will spring return to the fully closed position.

When the outdoor-air is below the enthalpy control setting

and the thermostat calls for cooling, the economizer outdoor-

air damper is opened proportionally to maintain between 50

and 56 F at the mixed-air sensor. If outside air alone cannot

satisfy the cooling requirements, economizer cooling is inte-

grated with mechanical cooling. When the room thermostat

is satisfied, the damper will spring return to the full closed

position. Additional information on economizer operation is

provided in the Ventilation Sequence section on page 27.

Time Guard

II Device

If the unit is equipped with accessory Time Guard II recycle

timer, the unit will delay 5 minutes between compressor starts.

Controls Kit

Loss-of-Charge/Low-Pressure Switch (LPS) — When the liq-

uid line pressure drops below 7 psig, the LPS opens 24-v power

to the compressor contactor and stops the compressor. When

the pressure reaches 22 psig, the switch resets and the com-

pressor is allowed to come back on.

High-Pressure Switch (HPS) — When the refrigerant high-

side pressure reaches 428 psig, the HPS opens 24-v power to

the compressor contactor and stops the compressor. When the

pressure drops to 320 psig, the switch resets and the com-

pressor is allowed to restart.

Freeze-Protection Thermostat (FPT) — When the evaporator-

coil leaving refrigerant temperature drops below 30 F, the FPT

opens 24-v power to the compressor contactor and stops the

compressor. When the leaving refrigerant temperature warms

to 45 F, the switch resets and the compressor is allowed to

restart.

III. INDOOR AIRFLOW AND AIRFLOW ADJUSTMENTS

CAUTION:

For cooling operation, the recommended

airflow is 300 to 500 cfm per each 12,000 Btuh of rated

cooling capacity. For heating operation, the airflow must

produce a temperature rise that falls within the range

stamped on the unit rating plate.

Adjust evaporator-fan speed to meet jobsite conditions.

Table 3 shows fan rpm at motor pulley settings. Table 4 shows

maximum amp draw of belt drive motor. Refer to Tables 5-18

to determine fan speed settings.

A. Direct Drive Motors

The evaporator-fan motor factory speed setting is shown on

label diagram affixed to base unit. If other than factory set-

ting is desired, refer to label diagram for motor reconnection.

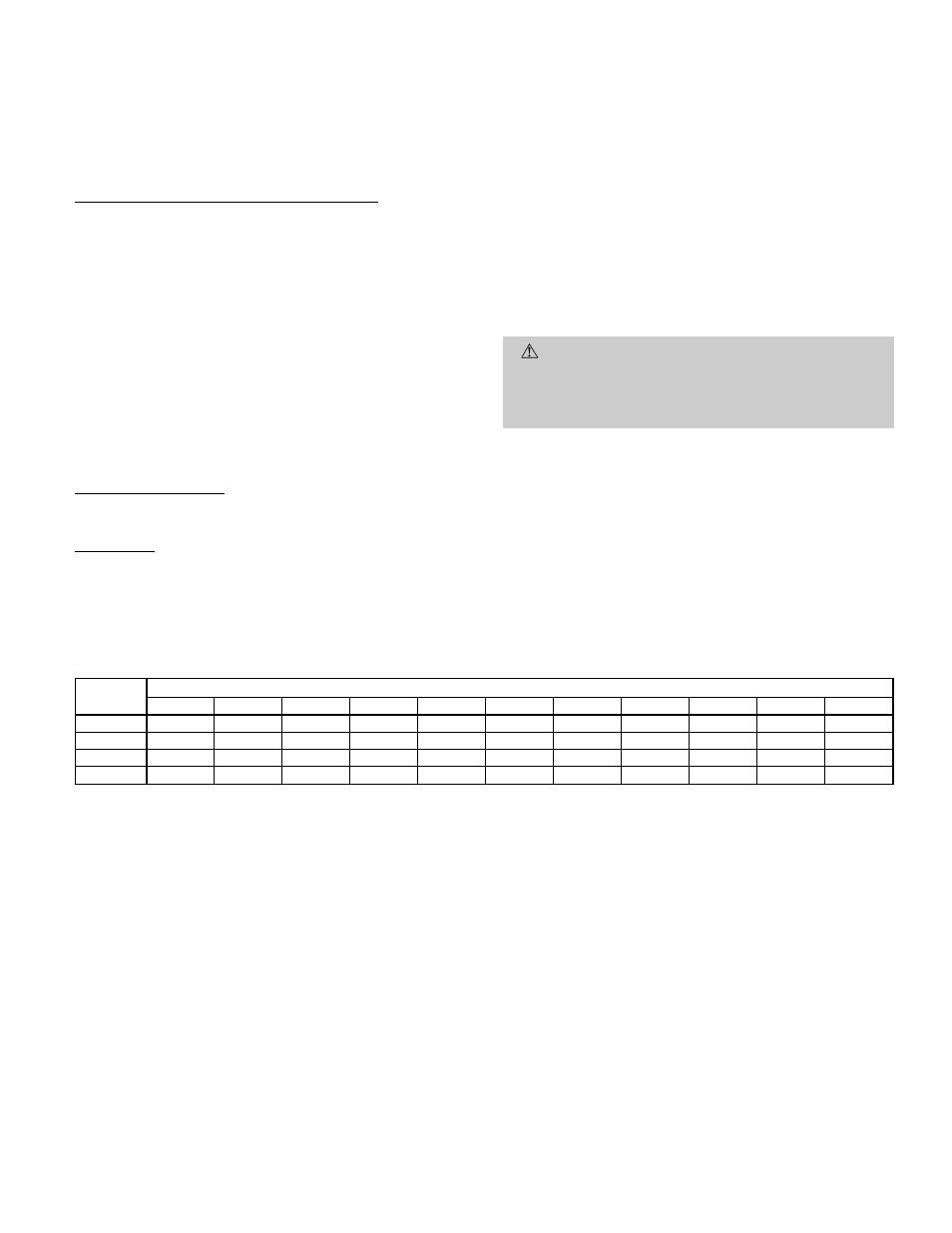

Table 3 — Fan Rpm at Motor Pulley Settings*

UNIT

558D

MOTOR PULLEY TURNS OPEN

0

1

⁄

2

1

1

1

⁄

2

2

2

1

⁄

2

3

3

1

⁄

2

4

4

1

⁄

2

5

036†

1090

1055

1025

990

960

925

890

860

825

795

760

048†

1185

1150

1115

1080

1045

1015

980

945

910

875

840

060†

1300

1260

1220

1180

1140

1100

1060

1020

980

940

900

072**

1460

1420

1380

1345

1305

1265

1225

1185

1150

1110

1070

*Approximate fan rpm shown.

†Indicates alternate motor and drive package.

**Indicates standard motor and drive package.

—19—