Appendix b design verification test procedure – BenQ DLP PROJECTOR PE8700 User Manual

Page 14

13

Appendix B Design Verification Test Procedure

1.Purpose

This standard establishes the environmental specification for projector related

products, which defines the level of product performance and reliability in the field. It is not

necessary the intent of these specification to simulate a typical user environment, but rather

to provide for a level of product robustness that when applied over a wide range of

manufacturing variability and environmental usage conditions.

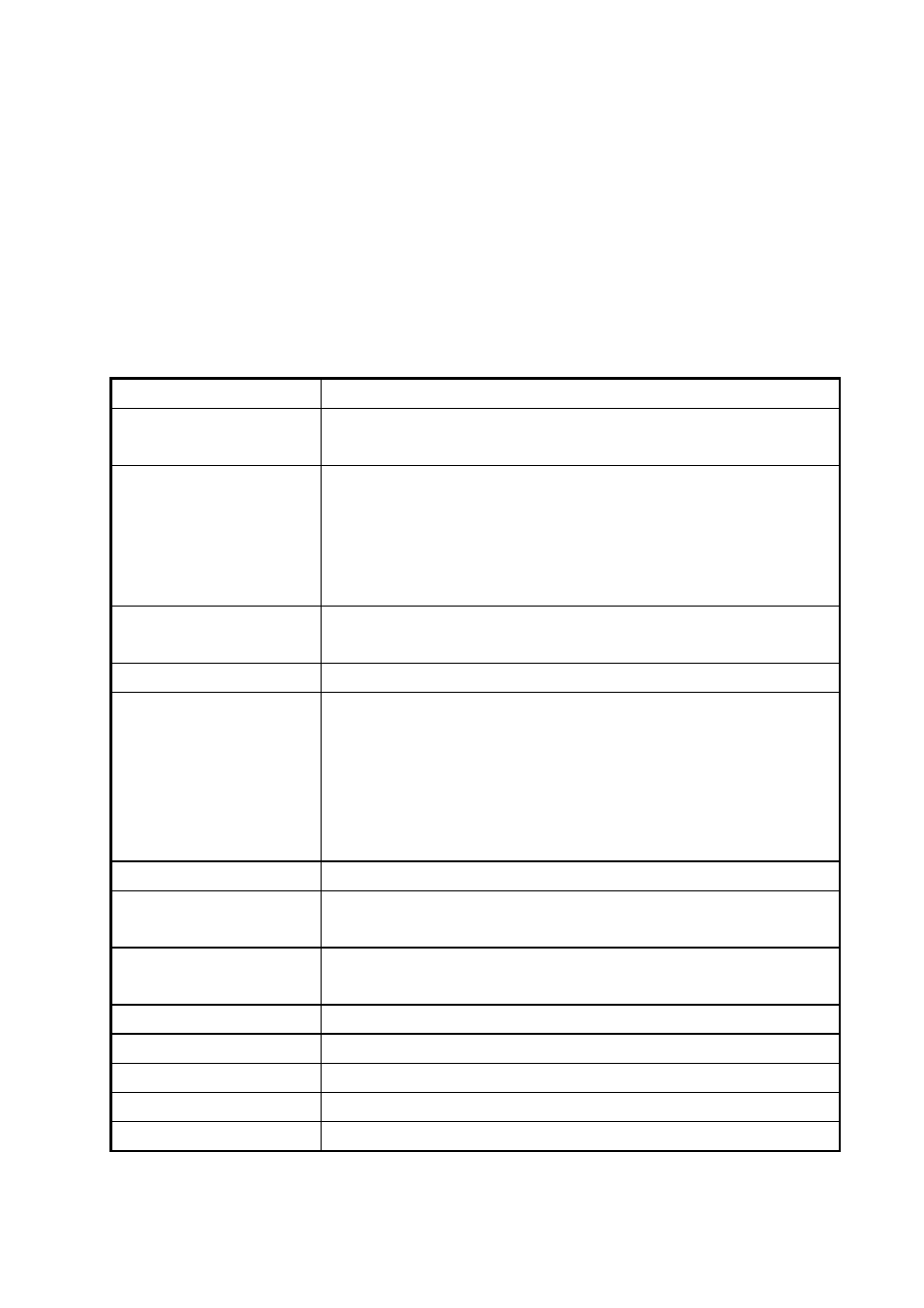

2.Test Summary

Dynamic Testing

Specification

Package Drop

76cm, 1 drop per orientation, all 6 primary surfaces, plus a selected

corners, and three selected edges, total of 10 drops

Package Vibration

Random

, 0.01g2/Hz, 5~100Hz, all primary axis, 20 min per orientation,

total of 60min

Sine

, 0.5g, 5~200Hz, 1 octave/min, 15 min dwell on each resonant

frequency, all primary axis, one sweep (30min minimum) per orientation,

total of 90+min

Shock, non-operating

50g, 20ms half-sine, all primary axis, 1 shock per orientation, total of 3

shocks

Security Lock

150N break away force

Fragility

Shock

, 50g, 20ms half-sine, all primary axis, 1 shock per orientation, total

of 3 shocks

Accelerate Life Test (operating)

, 65 oC, 72hr

Thermal shock(bare board),

-65~125 oC, 48hr

Input Voltage

, 90~264V

Input RGB signal

, 0.7V±0.1

Atmospherics

Temperature/Humidity,

operating

10~35oC/10~80RH, 48hr

Temperature/Humidity,

non-operating

-10~70oC/10~80RH, 48hr

Altitude, operation

0~6000ft@30oC, 4hr

Safety/EMC

UL/cUL

TUV Rheinland

Fcc/CE/C-Tick