Iso2 manifold mount variant, Installation, Pneumatic installation – Norgren VP51 DeviceNet Installation Instructions User Manual

Page 4: Electrical installation

4

5. INSTALLATION

Pneumatic Installation

• Supply Pressure:

15psig above maximum output required

(200psig

max.)

• Output Pressure Range:

0-150psig

• Media:

clean, dry 50µ filtered air

• Porting:

G1/4; 1/4NPT; ISO2 Manifold Mount

• Use oil-free air

• Do not use PTFE tape

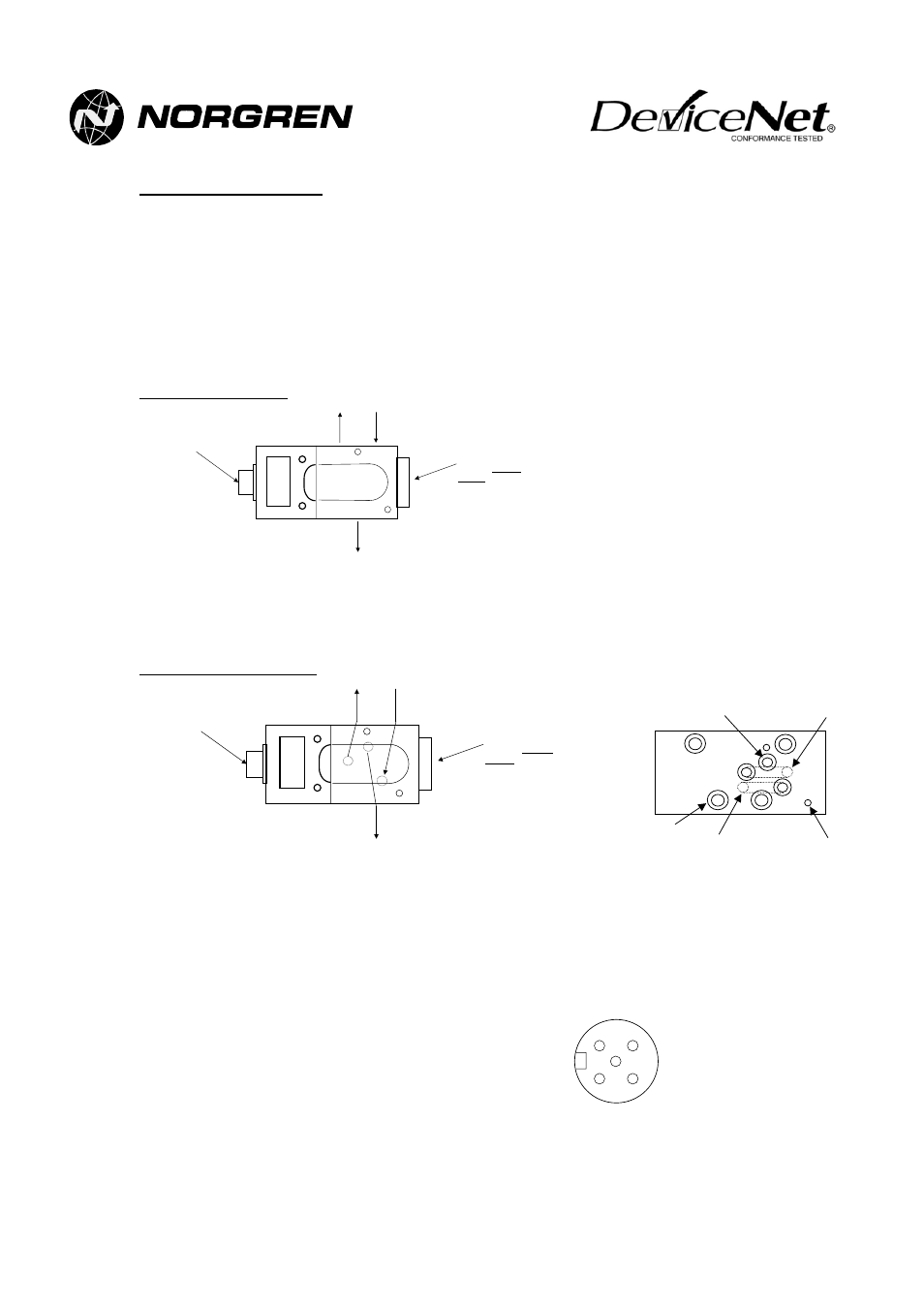

G1/4 & 1/4NPT variants

Electrical

connector

Return spring

housing. Do not

adjust.

Exhaust port (3

)

Supply

port

(1)

Output port (2)

1

3

2

• Connect pipe-work using 10mm OD, 8mm ID, plastic pipe, cut cleanly at right angles, with push-fit pipe

connections.

• Fit an exhaust silencer to Port 3 if required (this will only slightly degrade exhaust performance)

ISO2 Manifold Mount variant

Electrical

connector

Return spring

housing. Do not

adjust.

Exhaust port (3

)

Supply

port

(1)

Output port (2)

Output port (2)

Exhaust port (3)

Supply port (1)

ISO-2 sub base

mounting holes

VP51 mounting holes

(M4 tapped) x 2

• Use grub screws provided to plug cross drilled holes in interface plate

• Mount interface plate to ISO-2 sub base with four M6 screws, with gasket between plate and sub base.

• Place three O-rings in three counterbored holes in plate and mount VP51 with two M4 screws.

Electrical Installation

Connect the unit as follows using DeviceNet approved screened cable and a M12 female connector or with a

ready made M12 DeviceNet cable:

1

2

4

5

3

Connector pinout

looking onto the end of

the instrument

Pin 1:

Drain (bare)

Pin 2:

V+ (red)

Pin 3:

V- (black)

Pin 4:

CAN_H (white)

Pin 5:

CAN_L (blue)