2 boost stage design steps, An364 – Cirrus Logic AN364 User Manual

Page 22

AN364

22

AN364REV3

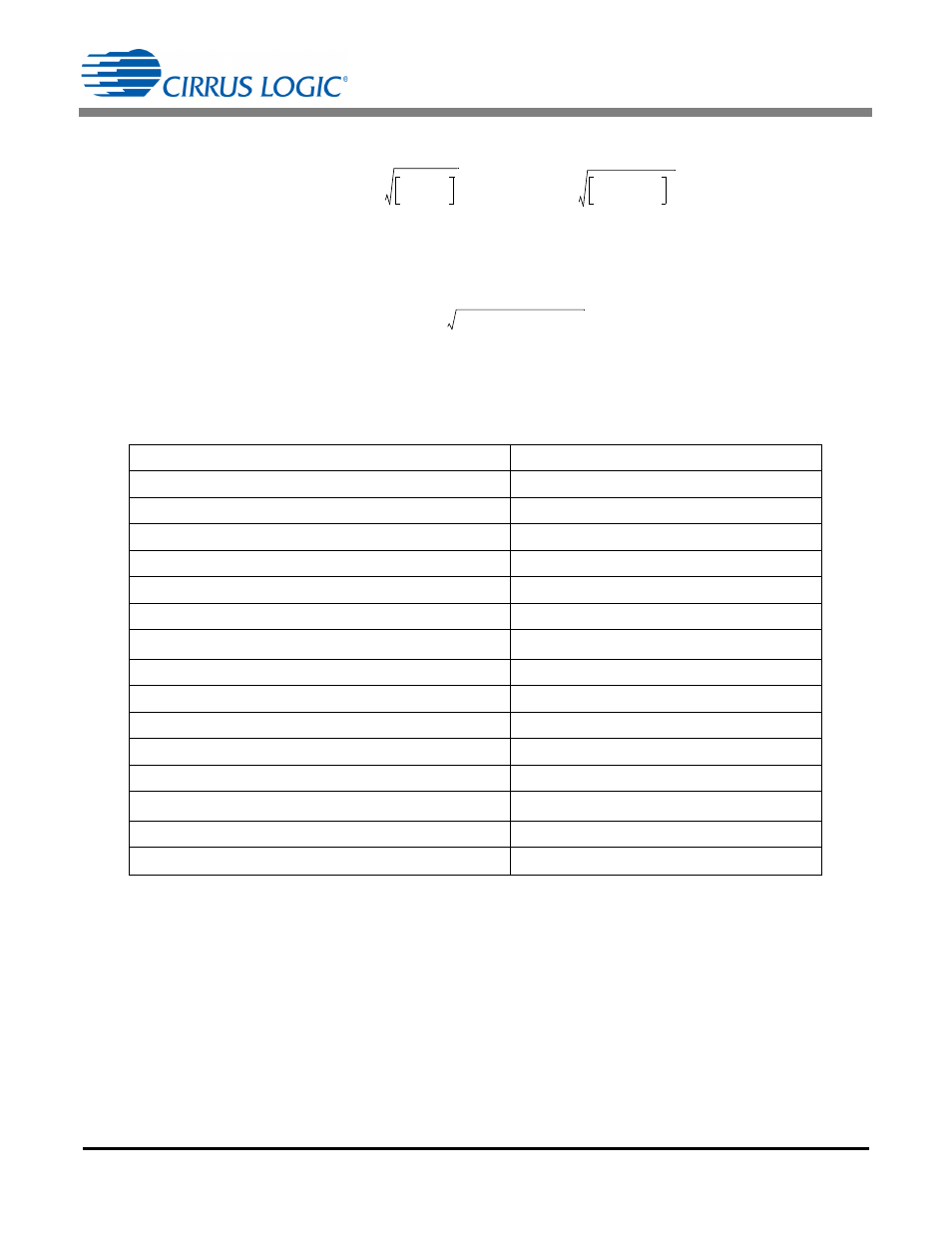

calculate the transformer T1 secondary RMS current:

Step 11) Determine Output Capacitor

Output capacitor C5 ripple current I

Ripple(RMS)

is the vectorial difference between transformer T1 secondary

current and the DC load current. See Equation 39.

Output capacitor C5 is selected as a 100

F, 25V capacitor.

Step 12) Flyback Transformer Specification

Specifications for the flyback transformer T1 can now be compiled to enable suppliers to design within size

and cost constraints.

Step 13) Circuit Adjustments

Now that the transformer has been defined and built, it may need to be adjusted. For more information, see

Circuit Adjustments on page 11.

Validate that the system meets the operating criteria. This may require adjusting components like R

Sense

and

R

FBGAIN

. For more information, see Recalculate R

4.2 Boost Stage Design Steps

Using Equation 19, calculate I

PK(BST)

:

Parameter

Value

Output DC Power

6.6W

Converter Topology

CRM flyback

Switching Frequency

85kHz

Primary Inductance

11.3 mH

10%

Peak Primary Current

0.15A

Primary RMS Current

43mA

Turns Ratio N

P

/N

S

14.3

Secondary Voltage

15.4V

Secondary RMS Current

0.85A

Primary Leakage Inductance

<100

H

Primary Voltage

405V

Electrostatic Shield

Between primary and secondary winding

Auxiliary Winding Turns Ratio (N

P

/N

AUX

)

20

Auxiliary Wire

Any convenient gauge

Rigidity Sec

Core/Primary/Aux/Shield

>2,500V

I

RMS

I

PK FB

N

T

current

3 TT

--------------------

=

0.131A 14.3

7.45

s

3 12.5

s

----------------------------

850mA

=

=

[Eq. 38]

I

Ripple RMS

0.85A

2

0.44A

2

–

0.73A

=

=

[Eq. 39]

I

PK BST

3.64 P

IN

V

RMS

---------------------------

3.64 7.3W

230V

--------------------------------

116mA

=

=

=

[Eq. 40]