Adjustment of zero point / span – WIKA S-10 User Manual

Page 8

1604457.14 GB/D/F/E 12/2009

14 WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio S-10, S-11

1604457.14 GB/D/F/E 12/2009

15

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio S-10, S-11

Specifications

Oxygen version of model S-10

Pressure ranges

bar

As of 0 ... 0.1 / 50 INWC

Type of pressure

Gauge pressure

Materials

Wetted parts

316 Ti (up to 40 bar / 600 psi F 1058)

Internal transmission fluid

1)

Halocarbon oil

1)

Not for model with pressure ranges > 25 bar / 300 psi

Permissible temperature of

Medium

-20 ... +60 °C

-4 ... +140 °F

Functional test

Open pressure connections only after the system is without pressure!

Observe the ambient and working conditions outlined in section 7 „Technical

data".

Please make sure that the pressure transmitter is only used within the over-

load threshold limit at all times!

The output signal must be proportional to the pressure. If not, this might point to a

damage of the diaphragm. In that case refer to chapter 10 „Troubleshooting“.

When touching the pressure transmitter, keep in mind that the surfaces of

the instrument components might get hot during operation.

7. Starting, operation

GB

Z = Zero

S = Span

Female

connector

Sealing

Clamping

nut

Male

connector

Sealing

Case with

pressure

connection

Recommended recalibration cycle: yearly

For further information (+49) 9372/132-295

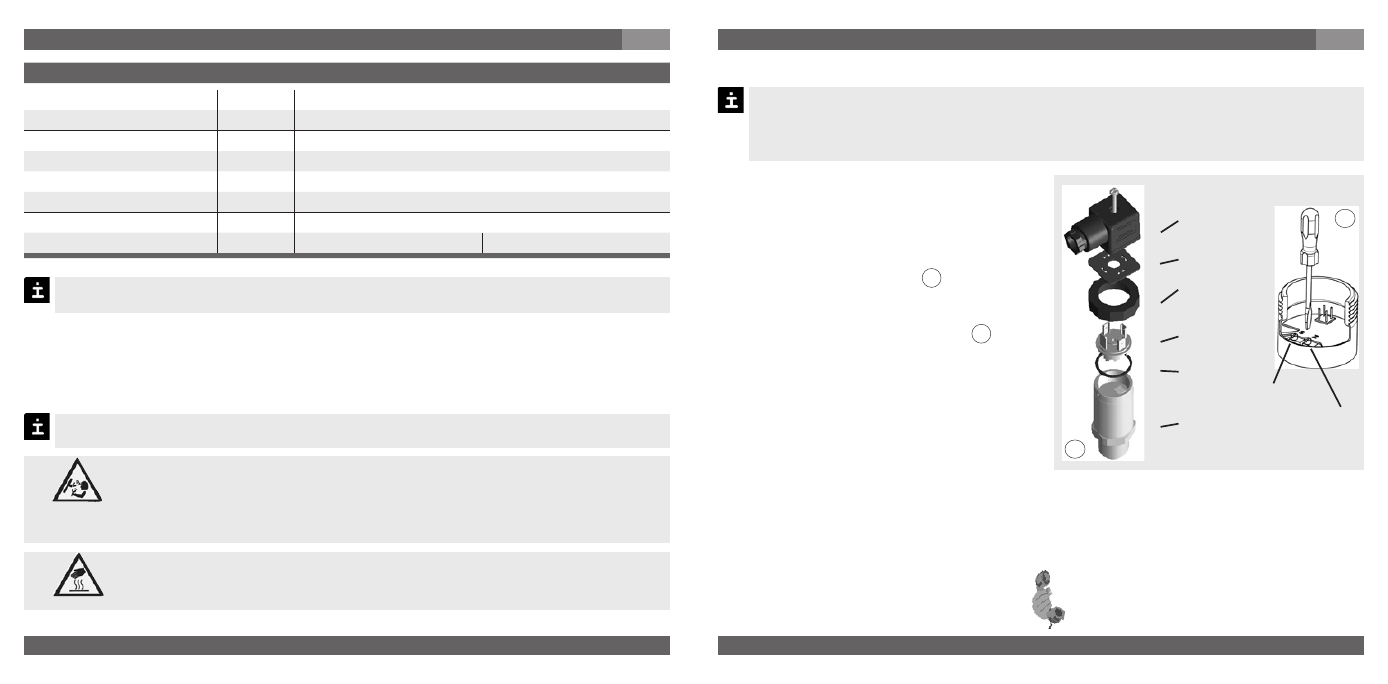

8. Adjustment of zero point / span

(only for pressure transmitter with clamping nut)

A

B

We do not recommend to adjust the span potentiometer. It is used for adjustment ex

factory and should not be adjusted by you unless you have adequate calibration equip-

ment at your disposal (at least three times more accurate than the instrument being

tested).

8. Adjustment of zero point / span

GB

Make sure wires are not cut or pinche

during disassembly and reassembly of

the connector.

Remove the female connector. Open

the pressure transmitter by detaching

the clamping nut (see Fig. A ). Carefully

remove the male connector from the

case.

Adjust the zero point (Z) (see Fig. B ) by

generating the lower limit of the pressure

range.

Adjust the span (S) by generating the

higher limit of the pressure range.

Check the zero point.

If the zero point is incorrect, repeat

procedure as required.

Reassemble the instrument carefully.

Make sure all sealings and o-rings are

not damaged and correctly installed to

assure the rated moisture ingress protec-

tion.

When designing your plant, take into account that the stated values (e.g.burst pressure,

over pressure safety) apply depending on the material, thread and sealing element used.

Warning

Caution