DuraVent PelletVent Pro User Manual

Page 9

9

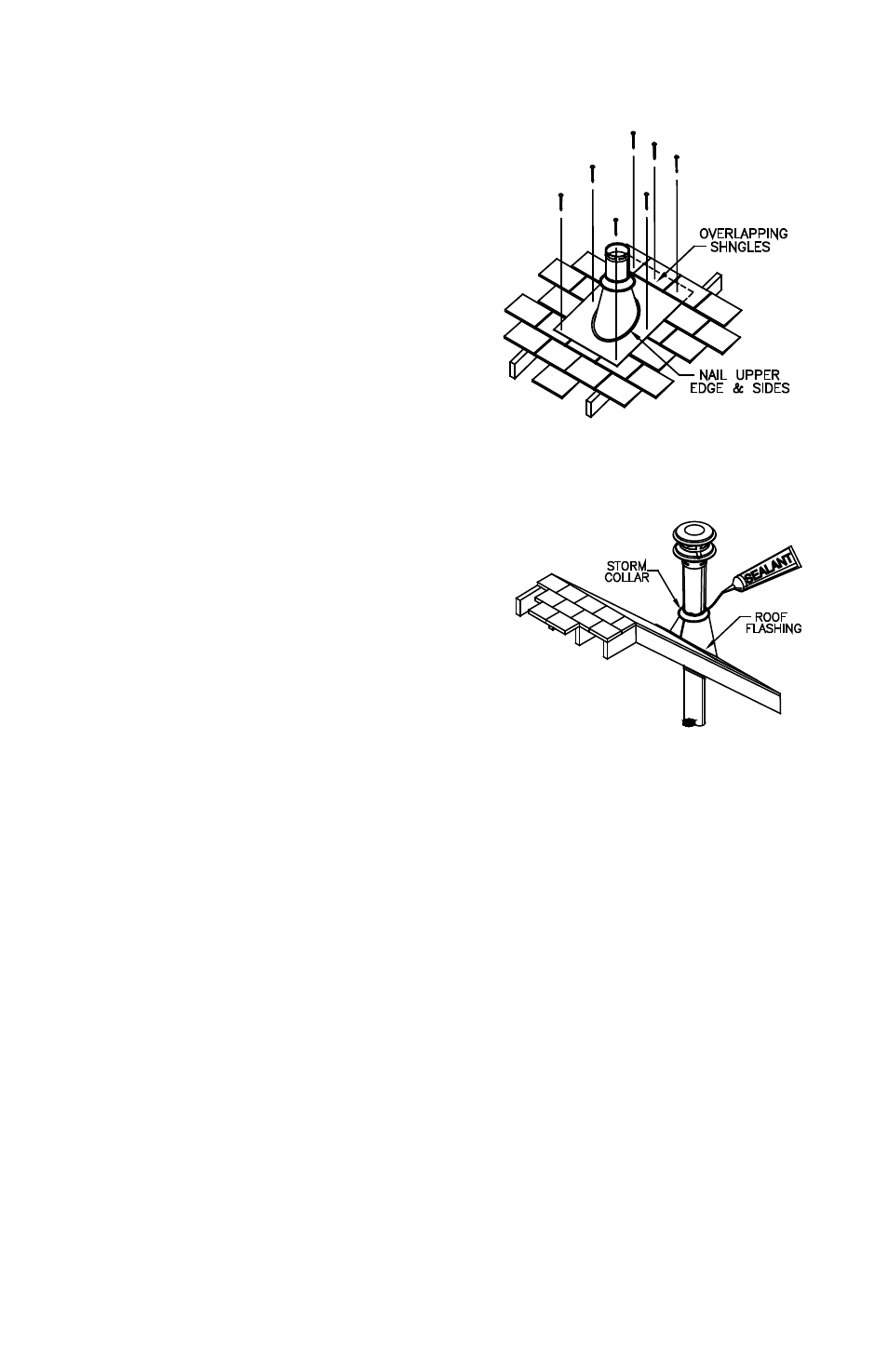

Figure 8

Pro pipe sections do not require any sealant;

however in certain instances high temp

silicone sealant may be used. Seal connection

where the inner liners overlap for best results

(Figure 5). Screws are not needed, but 1/4”

screws can be used if desired, however, be

sure you do not penetrate the inner liner.

E. When the pipe passes through the Ceiling

Support Firestop Spacer at ceiling, tighten

bolt and clamp around pipe. Where the vent

passes through additional floors and ceilings,

always install a Ceiling Support Firestop

Spacer.

F. ALWAYS MAINTAIN AT LEAST 1”

CLEARANCE FROM COMBUSTIBLE

MATERIALS TO THE VENT PIPE.

G. When the PelletVent Pro enters the attic,

install an Attic Insulation Shield around the

vent (Figure 6). This will prevent insulation

and debris from collecting near the vent

pipe. Use (4) nails or wood screws to secure

the base of the Attic Insulation Shield to the

framed opening. Adjust the height of the Attic

Insulation Shield by sliding the top cylindrical

shield over the one from the base. Ensure

that the top of the Shield is above the level

of building insulation. Secure the Shield in

place with at least two (2) sheet metal screws

through the side of the cylindrical shield.

Attach collar around pipe, then lower to the top

of the Attic Insulation shield.

H. After lining up for the hole in roof, using

the same method as 2. (B), cut either a round

or square hole in the roof (Figure 7). Always

cut the hole with the proper clearance to the

vent pipe. Install the upper edge and sides

of Flashing under the roofing materials and

nail to the roof along the upper edge and

sides (Figure 8). Do not nail across the lower

edge. Seal all nail heads with non-hardening

waterproof sealant.

I. To finish, apply non-hardening waterproof

sealant where the Storm Collar will meet the

vent and Flashing; slide Storm Collar down

until it rests upon the Roof Flashing (Figure 9).

Holding the base of Cap, firmly twist lock your

Vertical Termination Cap onto, supported Pipe

Section protruding through the roof line.

Figure 9