Making adjustments to your saw – SawStop ICS73600 User Manual

Page 64

62

SawStop 10” Industrial Cabinet Saw

Making Adjustments to Your Saw

Next, loosen the horizontal positioning bolts using an 8 mm hex L-wrench. Loosen the bolts just enough to

allow the clamp mounting bracket to slide along its mounting surface. Reinstall the blade and raise the blade

to the fully elevated position.

Place a straight edge along the right side of the blade, making sure the straight edge runs between the teeth of

the blade. Now adjust the position of the clamp until the right side of the spreader is flush and flat against the

straight edge. If necessary, pivot the right anti-kickback pawl up out of the way while performing this step.

Note: if you are using a thin-kerf blade (i.e., kerf

is 0.080 to 0.094 in.), you may need to place one

or more shims between the straight edge and

the side of the blade to ensure the spreader is

centered with the blade.

Once the spreader is positioned parallel to the

blade, check the distance between the curved,

front edge of the spreader and the edge of the

blade. There should be a gap of approximately

5-7 mm between the center-point of the arc on

the front of the spreader and the rear edge of the

blade (see Fig. 72). If necessary, slide the clamp

forward or backward until the spacing between the

blade and the spreader is approximately correct.

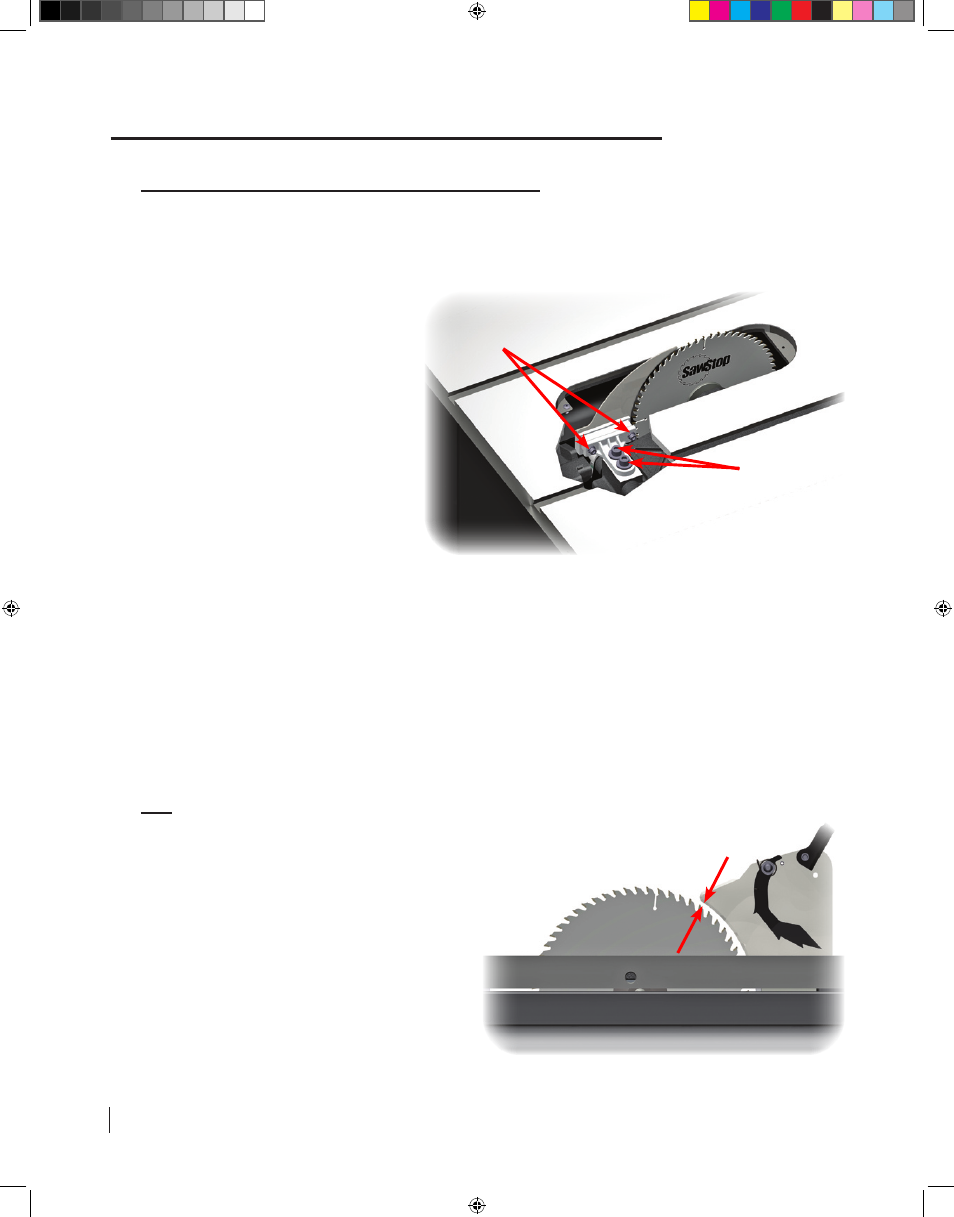

7. Aligning the Riving Knife and Spreader to the Blade:

For safe operation, the spreader and riving knife should be aligned parallel to the blade, and positioned inside

the kerf of the blade. The spreader, or alternatively, the riving knife, is held in position by a quick-release clamp

mounted under the table and behind the blade (see Fig. 71). Once the clamp is properly adjusted, the spreader

and riving knife will automatically align to the blade when installed in the clamp.

To adjust the clamp, set the tilt angle to

0° and remove the table insert. Remove

the blade and set it aside for a moment.

Make sure the spreader is installed, and

lower the blade elevation to zero.

Fig. 72

gap should be

approximately 5-7mm

Fig. 71

horizontal

positioning bolts

vertical

positioning bolts

Industrial Cabinet Saw Rev. 2 Ma62 62

3/9/2010 8:39:03 AM