Using your saw – SawStop ICS73600 User Manual

Page 38

36

SawStop 10” Industrial Cabinet Saw

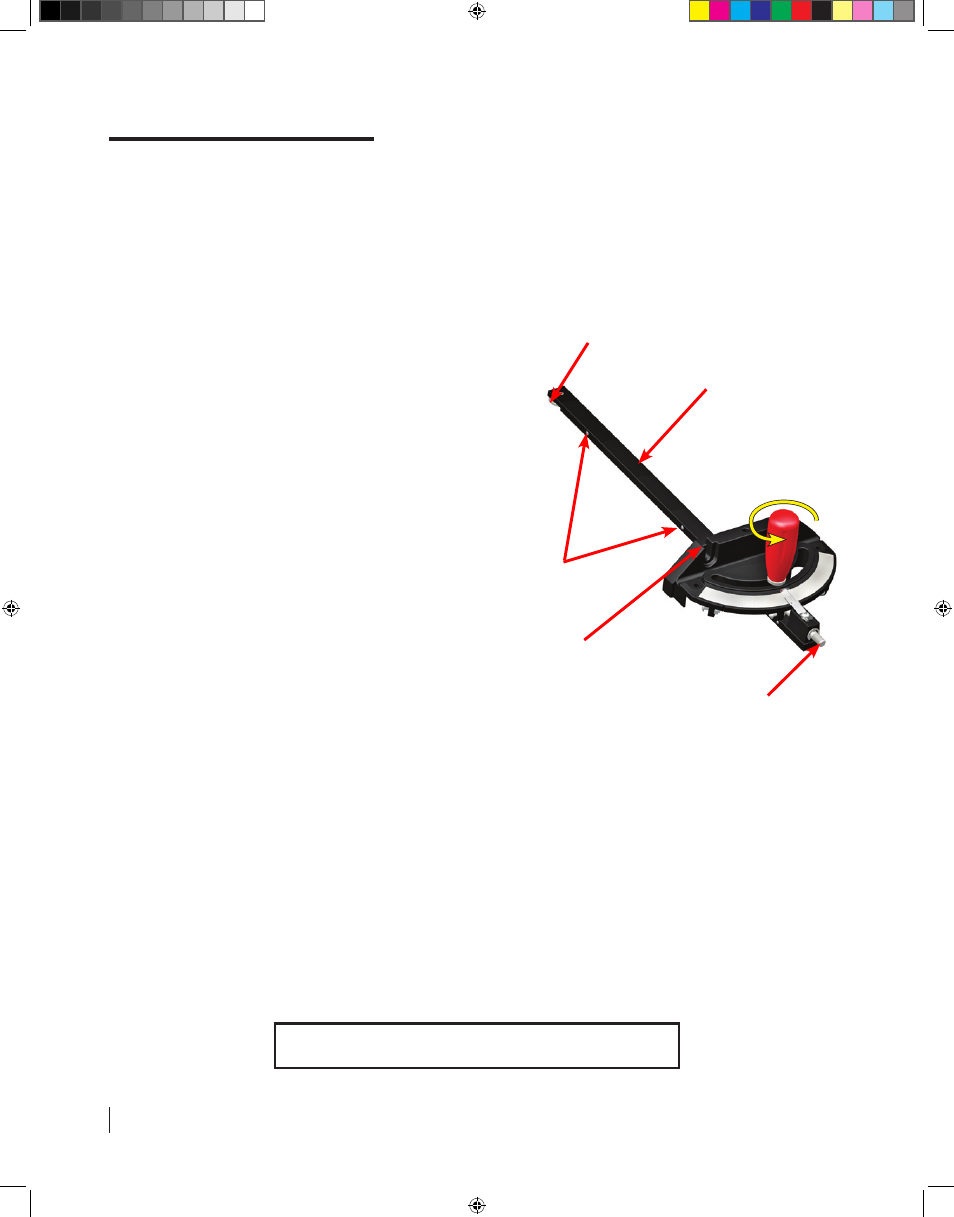

A guide plate is mounted on the end of the main bar (see Fig. 33) and fits in the bottom of the slots to hold the

front of the miter gauge in place when the miter gauge head is positioned in front of the forward edge of the

table. Three spring bearings are mounted in the side of the main bar to ensure the bar slides smoothly in the

slots without excessive play. These spring bearings are preset at the factory to allow smooth operation of the

miter gauge, and should not require further adjustment. If you wish to adjust the spring bearings, see page 66

for instructions.

The face of the miter gauge can be adjusted

between -60° and +60° relative to the blade. To

adjust the miter angle, turn the handle counter-

clockwise approximately

1

/

2

turn to unlock the miter

gauge head. Pull the indexing pin backwards until

it stops, and then rotate the head until the indicator

is positioned over the desired angle on the miter

gauge scale. Use an angle gauge to set the angle

between the miter gauge head and the blade if

precise alignment is needed. Once the angle is

correct, turn the handle clockwise to lock the miter

gauge head.

Adjustable index stops at -45°, 0°, and +45° are

provided to allow quick and precise alignment at

those angles. To use the index stops, rotate the

miter gauge head until the angle indicator reads

approximately 5° higher (more positive) than the

desired angle, and then push the indexing pin

forward until it stops. Next, rotate the miter gauge

head counter-clockwise until the index stop hits the

indexing pin, and then tighten the handle to lock

the gauge at the desired angle. The index stops

are preset at the factory to be within ± 0.5° of the

true angle, so further adjustment should not be

necessary. If you wish to adjust the index stops, see

page 66 for instructions.

For added safety, an optional wood face can be mounted to the miter gauge face to provide additional support

when cutting large or small workpieces. To mount the face, use wood screws with shanks sized to fit through

the slots in the miter gauge head. The wood face should be at least 1 inch higher than the maximum depth of

cut, and should extend beyond the edges of the miter gauge head.

When using the miter gauge, start with the workpiece and miter gauge well in front of the blade. Place your

hand closest to the blade on the miter gauge handle, and your other hand on the workpiece opposite the blade

(see Figs. 34 and 35 on page 37). Make sure the workpiece is held squarely and firmly against the miter gauge

face and the table. Move the miter gauge and workpiece slowly and smoothly past the blade. For through-cuts,

shift the workpiece slightly away from the blade before pulling the miter gauge and workpiece back toward

the front of the saw. Do not touch the portion of the workpiece that was cut off until the blade has completed

coast-down.

Using Your Saw

WARNING! Never make free-hand cuts. Never hold or touch

an unsupported piece of wood while the blade is spinning.

Fig. 33

guide plate

main bar

spring

bearings

miter gauge

head

indexing

pin

turn locking

handle to unlock

miter gauge head

Industrial Cabinet Saw Rev. 2 Ma36 36

3/9/2010 8:38:44 AM