Making adjustments to your saw – SawStop ICS73600 User Manual

Page 56

54

SawStop 10” Industrial Cabinet Saw

To do this, set the tilt angle back to 0° and reposition the dial test indicator as described above. When you slide

the dial indicator mount across the blade, you should see little or no change in the indicator readout since the

table was previously aligned. Now, slide the dial indicator toward the rear of the saw until the measurement arm

is about

1

/

2

inch inside the rear edge of the blade. Set the readout to zero.

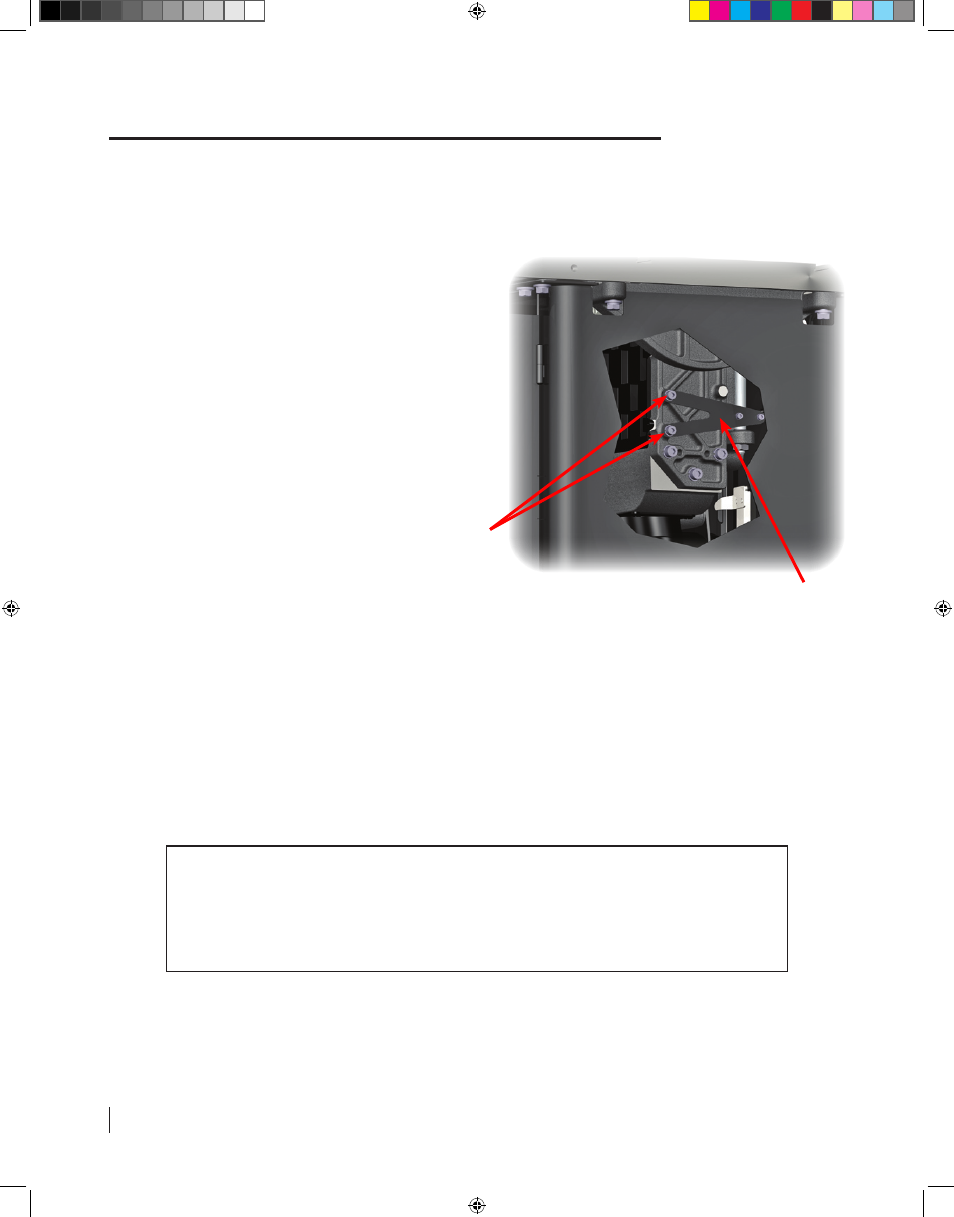

The angle of the blade relative to the tilt axis is

controlled by a v-bracket that connects the rear

elevation shaft to the rear trunnion (see Fig. 59). The

v-bracket is connected to the rear trunnion by two bolts

that extend through oversized holes in the v-bracket.

The oversized holes allow the position of the v-bracket

to be adjusted relative to the rear trunnion.

Using the 6 mm hex L-wrench, loosen the bolts just

enough to allow the v-bracket to move when force

is applied. You can access the bolts by opening the

motor cover.

Making Adjustments to Your Saw

For example:

if the difference between the first and second measurements was +0.006 inch,

then the misalignment at 0° should be adjusted to (-2.5)

x

(0.006) = -0.015 inch

To align the blade to the tilt axis, you need to adjust the position of the v-bracket until the misalignment

between the blade and the miter slot at a 0° tilt angle is 2.5 times the difference between the first and second

measurements, but in the opposite direction.

Fig. 59

v-bracket

bolts

Industrial Cabinet Saw Rev. 2 Ma54 54

3/9/2010 8:38:58 AM