The sawstop safety system – SawStop ICS73600 User Manual

Page 12

10

SawStop 10” Industrial Cabinet Saw

The SawStop Safety System

This table saw is equipped with the SawStop

®

safety system. This revolutionary technology was developed to

reduce the potential for a serious injury in the event of accidental contact with the saw blade. SawStop

®

table saws

are the first saws ever built to be smart enough to know the difference between you and the wood you are cutting.

The SawStop

®

safety system includes

two components, an electronic detection

unit and a fast-acting brake. The electronic

detection unit detects when a person contacts

the blade. A small electrical signal is induced

onto the blade by electrodes placed around

the arbor. Although this low voltage, high

frequency signal is too small to feel, it can

be measured by the detection system. When

human skin comes into contact with the blade

(or arbor), a portion of the signal is absorbed

by the body due to the inherent electrical

capacitance of the human body. As a result,

the signal on the blade gets smaller and the

detection unit recognizes this as contact.

Wood and other non-conductive

materials such as plastic, foam, cardboard,

Corian

®

, melamine, etc., do not cause a drop

in the signal because those materials do not

absorb the signal on the blade. Conductive

materials such as aluminum and other metals,

carbon fiber materials, mirrored acrylic, carbon-filled materials, etc., will typically cause the brake to activate. If you

need to cut these conductive materials, the safety system can be placed in “Bypass” mode to temporarily disable

the brake. (See page 33 for instructions on how to use the saw in Bypass mode.)

The fast-acting brake includes a small fuse that holds a strong spring in compression. If the electronic detection

unit detects contact while the blade is spinning (including during coast down), the fuse is burned by a surge of

electric current. The spring then pushes an aluminum brake into the teeth of the spinning blade. The teeth cut into

the brake, stopping the blade. The total time between the detection of contact and stopping the blade is just a few

milliseconds. If the brake is activated while the blade is at or near full speed, the blade will also quickly retract below

the table. The system will not activate the brake when the blade is stopped–even if you spin the blade by hand. This

allows you to touch or change the blade when the motor is off just as with ordinary table saws. However, for safety,

always switch the Main Power and Disconnect switches to OFF when changing the blade.

The SawStop

®

safety system is active whenever the Main Power is on. The safety system continuously performs

many different self-checks to ensure that the components of the system are operating properly. If any problems are

detected, the safety system will disable the motor and display a system status code to identify the problem (see

page 30 for a description of the system status codes and the corrective action). If the problem is detected while the

motor is spinning, the motor will be shut off. The safety system will not allow the motor to be started, even in Bypass

mode, as long as a problem is detected.

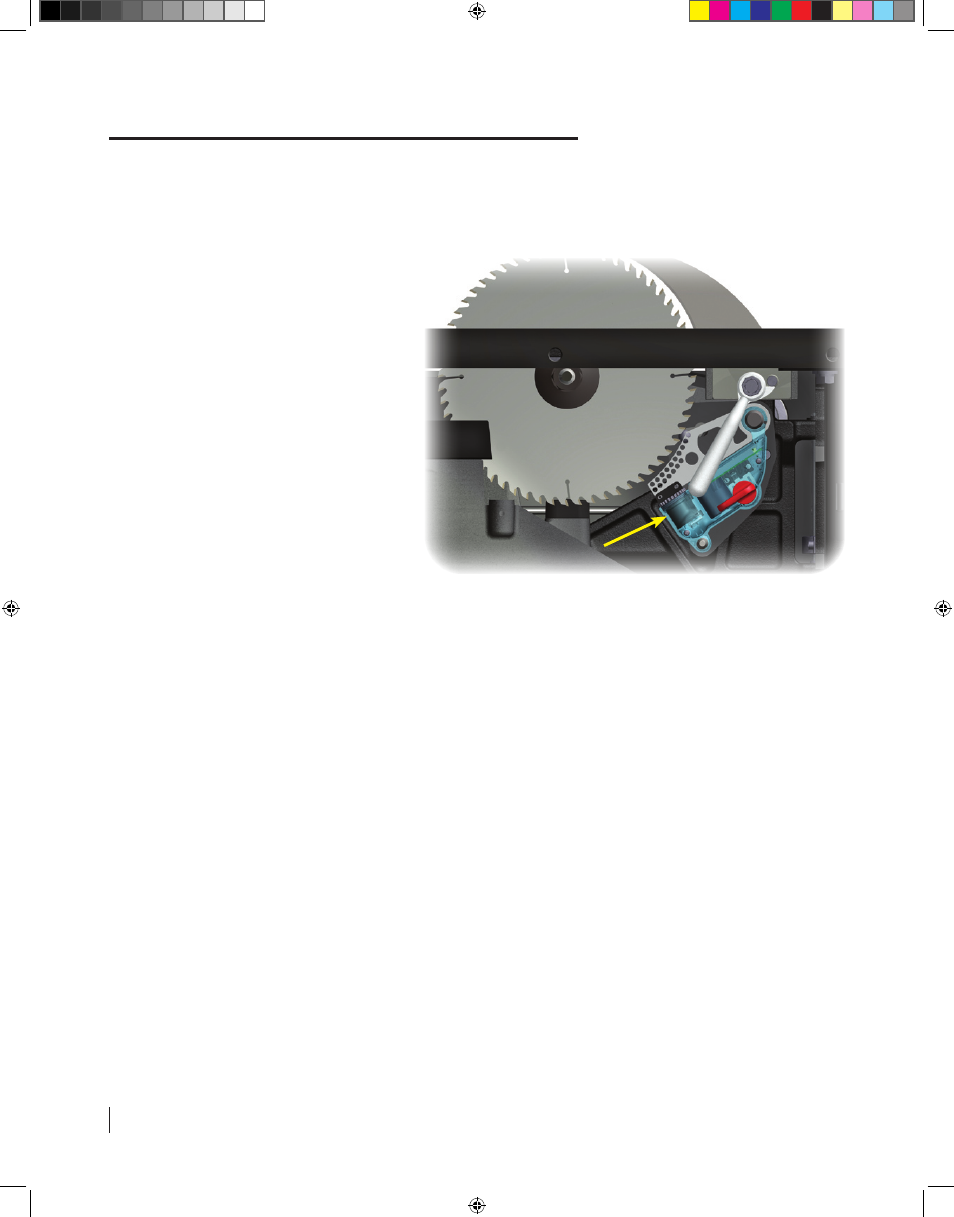

The electronic detection unit and fast-acting brake are contained in the “brake cartridge,” which is positioned

under the table and just behind the blade (see Fig. 1). The brake cartridge must be correctly installed before the

motor can be started (see page 40 for instructions on removing/installing the brake cartridge). In the event that the

brake is activated, a new brake cartridge must be installed before the saw can be used again.

Fig. 1

Brake Cartridge

Industrial Cabinet Saw Rev. 2 Ma10 10

3/9/2010 8:38:30 AM