Goulds Pumps 3296M - IOM User Manual

Page 47

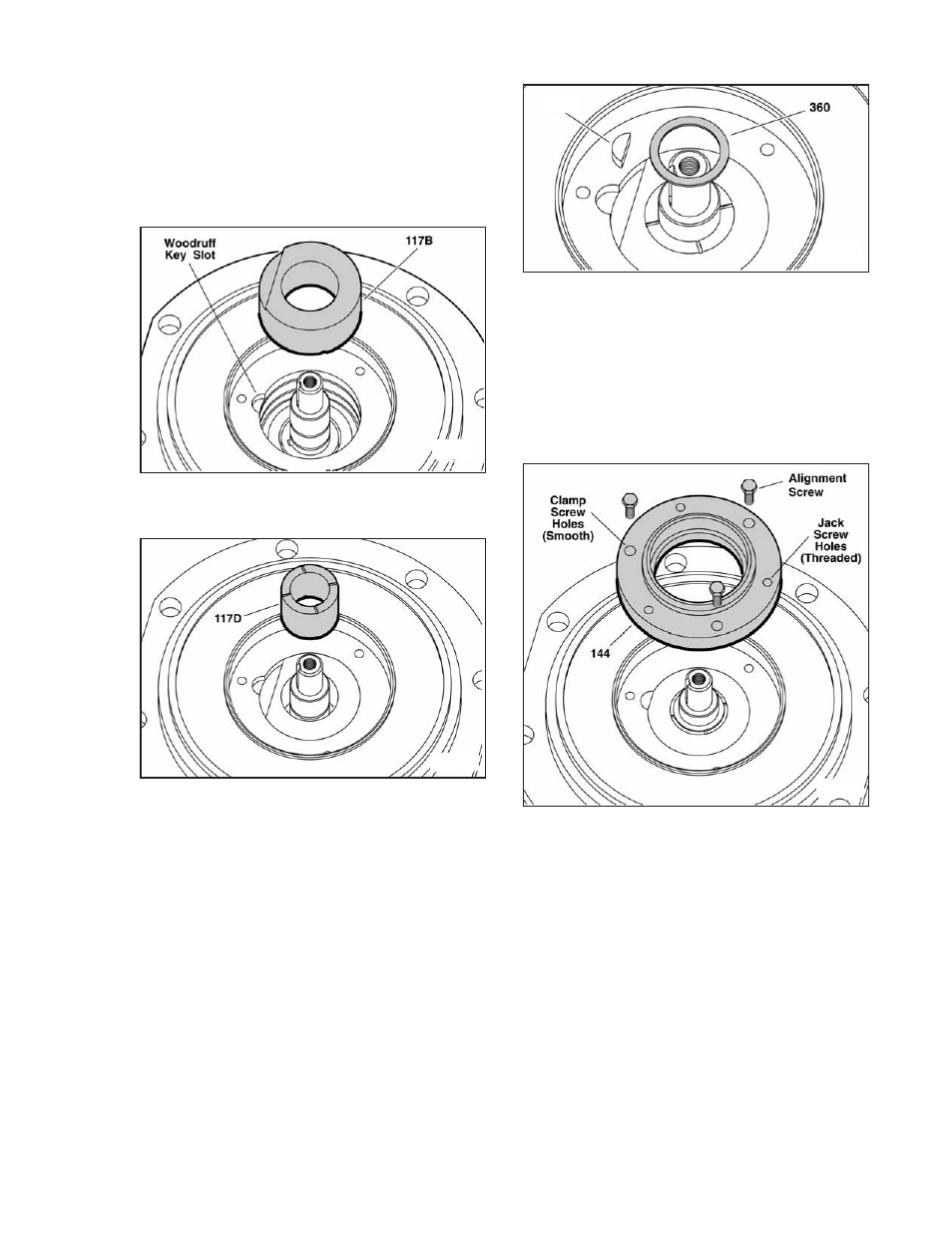

23. Press inboard stationary sleeve bearing (117B)

into frame adapter (108) by hand using bearing

driver. The stationary inboard key slot in the

inboard stationary bearing (117B) must line up

with the woodruff key slot in the frame adapter

(108) as shown. Press inboard stationary bearing

in by hand using bearing driver (Fig. M).

24. Press inboard rotary sleeve bearing (117D) onto

driven shaft (122A) using bearing driver (Fig. N).

25. Install stationary inboard bearing key (178K) in

frame adapter (108) (Fig. O).

26. Install the fourth spacer gasket (360) (Fig. O) and

shoulder against face of inboard rotary sleeve

bearing (117D).

27. Install wear ring (144) (Fig. P). Place wear ring

alignment screws through unthreaded holes in

wear ring (144) and thread into wear ring bolt

holes in frame adapter (108). These are used to

align the wear ring holes in the frame adapter

(108). Press wear ring (144) into the frame adapter

(108). Remove alignment screws after wear ring is

in place.

28. Install flush screen (187) (Fig. Q).

29. Install wear ring clamp screws (353B) (Fig. Q).

3296 M Group 6/05

43

Fig. M

Fig. N

Fig. O

178K

Fig. P