Maintenance of bearings, Oil lubricated bearings – Goulds Pumps 3296M - IOM User Manual

Page 28

MAINTENANCE OF BEARINGS

OIL LUBRICATED BEARINGS

Oil level is measured through sight glass. Oil level

must not fall below center of site glass. An increase in

level may be noted after start up due to oil circulation

within the bearing frame. Change Oil after 200 hours

for new bearings, thereafter every 4000 operating

hours or 6 months, which ever period is shorter.

Change oil every 2000 operating hours under severe

operating conditions, such as high temperature services

[pumpage temperatures in excess of 325°F (160°C)].

We recommend using Table 5 to help determine your

lubricating oil needs.

24

3296 M Group 6/05

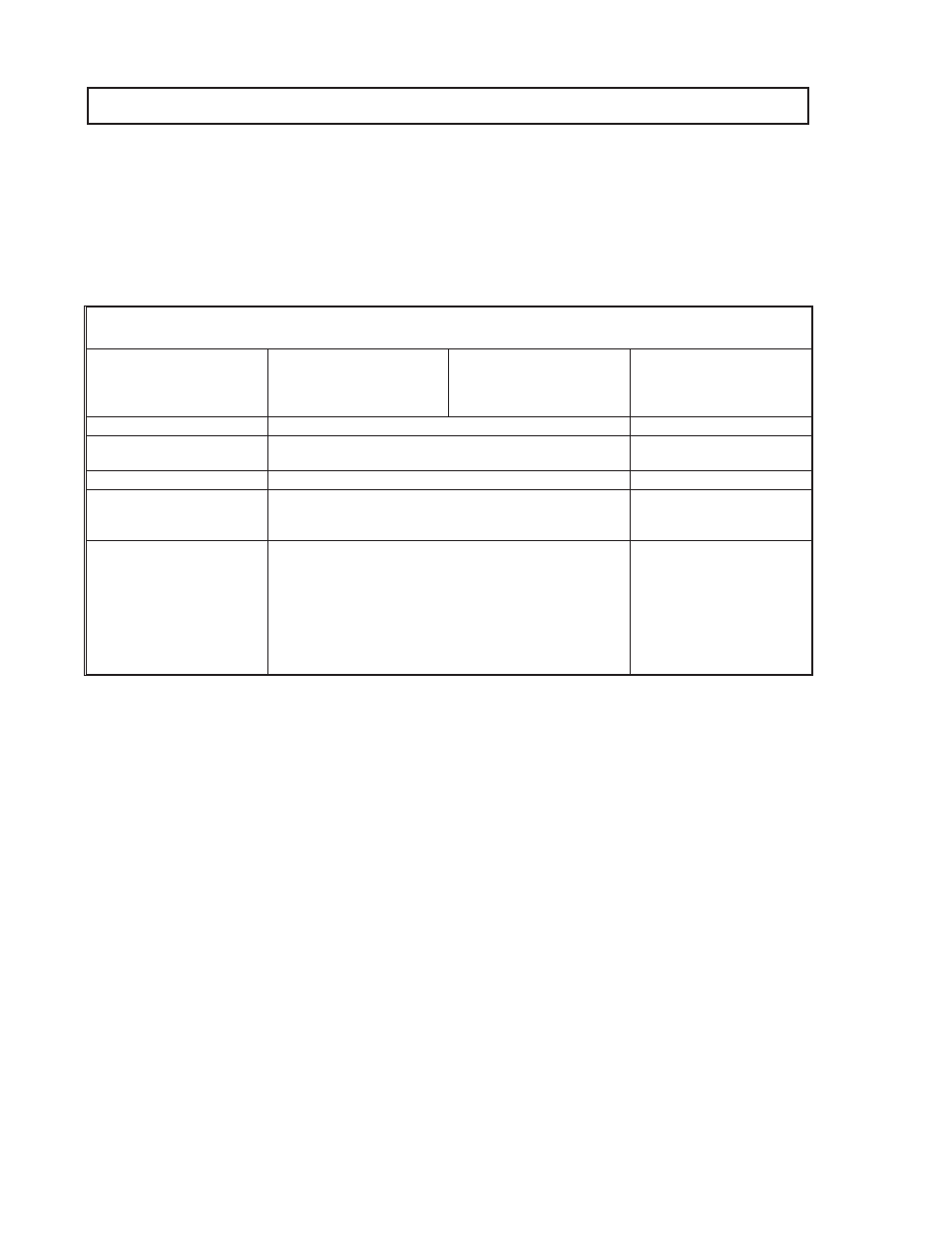

Table 5

Bearing Frame Lubrication Requirement

Oil Grades

Pumpage Temp. of

less than 325°F (160°C)

Pumpage Temp. of

325° - 375°F

(160° - 190C°)

with bearing frame cooling

Pumpage Temp. of

greater than 375°F

(190°C)

with bearing frame cooling

ISO Grade

VG 68

Synthetic VG 68

Approximate SSU

100°F (38°C)

300

Synthetic 300

DIN 51517

C 68

Synthetic C68

Kenematic Viscosity at 40°C

(105°F)

(mm

2

/sec)

68

Synthetic 68

Acceptable

Exxon

Teresstic EP 68

Chevron

GTS Oil 68

Mobil

DTE 26

Gulf

Harmony 68

Shell

Tellus Oil 68

Phillips

Mangus Oil 315

Phillips

MM SAE 20-20W

Phillips

HDS SAE 20-20W

Royal Purple Synfilm 68

NOTE: This is a list of oils that meet the lubrication requirements of this pump. It is not intended to be an

endorsement of products listed nor exclude other oils that meet these requirements.