Goulds Pumps 3296M - IOM User Manual

Page 29

3296 M Group 6/05

25

Table 6

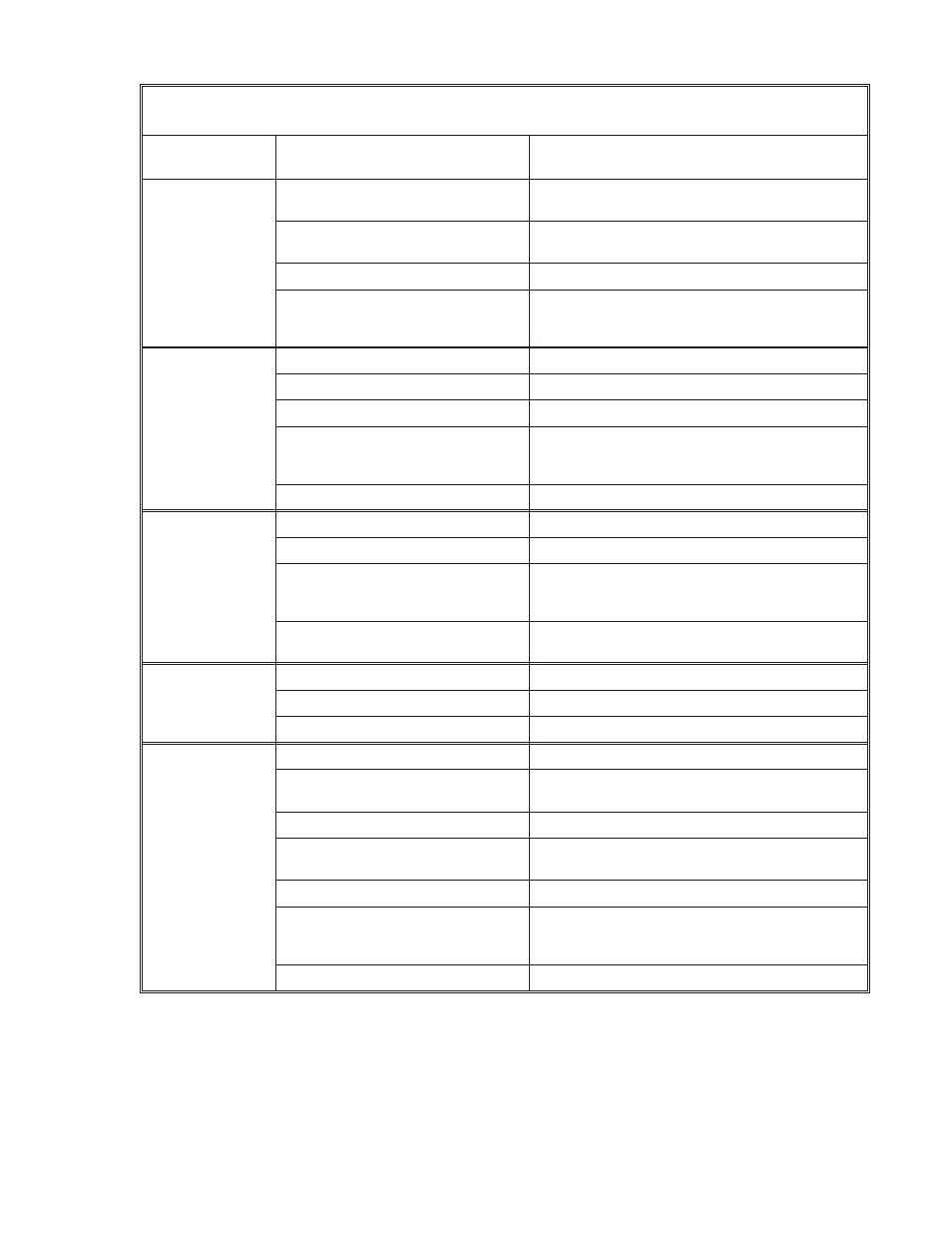

Troubleshooting Pump

PROBLEM /

MALFUNCTION

PROBABLE CAUSE

REMEDY

No liquid delivered

Pump not primed.

Reprime pump, check that pump and

suction line are full of liquid.

Suction line clogged.

Check suction line pressure. If low,

locate and remove obstructions.

Impeller clogged with foreign material.

Disassemble and remove blockage.

Magnet de-coupling

Shut down. Check temperature and

viscosity of pumpage. Check magnets

with breakaway torque test.

Pump not

producing rated

flow or head

Air leak in suction line

Check for leakage and correct.

Impeller partly clogged

Back flush pump to clean impeller

Worn impeller rings

Replace defective part as required

Insufficient suction head

Ensure that suction line shutoff valve is

fully open and line is unobstructed.

Check suction pressure

Worn or broken impeller

Inspect and replace if necessary

Pump starts then

stops pumping

Improperly primed pump

Reprime pump

Air leak in suction line

Check for leakage and correct

Magnet de-coupling

Shut down. Check temperature and

viscosity of pumpage. Check magnets

with breakaway torque test.

Air or vapor pockets in suction line

Rearrange piping as necessary, to

eliminate air pockets

Bearings run hot

Improper lubrication

Check lubricant for suitability and level

Lube cooling

Check cooling system

Improper alignment

Check pump alignment

Pump is noisy or

vibrates

Improper pump/driver alignment

Align shafts

Partly clogged impeller causing

imbalance

Disassemble and remove blockage

Broken or bent impeller or shaft

Replace as required

Base not rigid enough

Tighten hold down bolts of pump and

motor or adjust stilts. Check grout.

Worn bearings

Replace

Suction or discharge piping not

anchored or properly supported

Anchor per Hydraulic Institute Standards

recommendations (Edition 14, Centrifugal pump

section).

Pump is cavitating

Increase NPSH available.