Warning – Goulds Pumps 3296M - IOM User Manual

Page 45

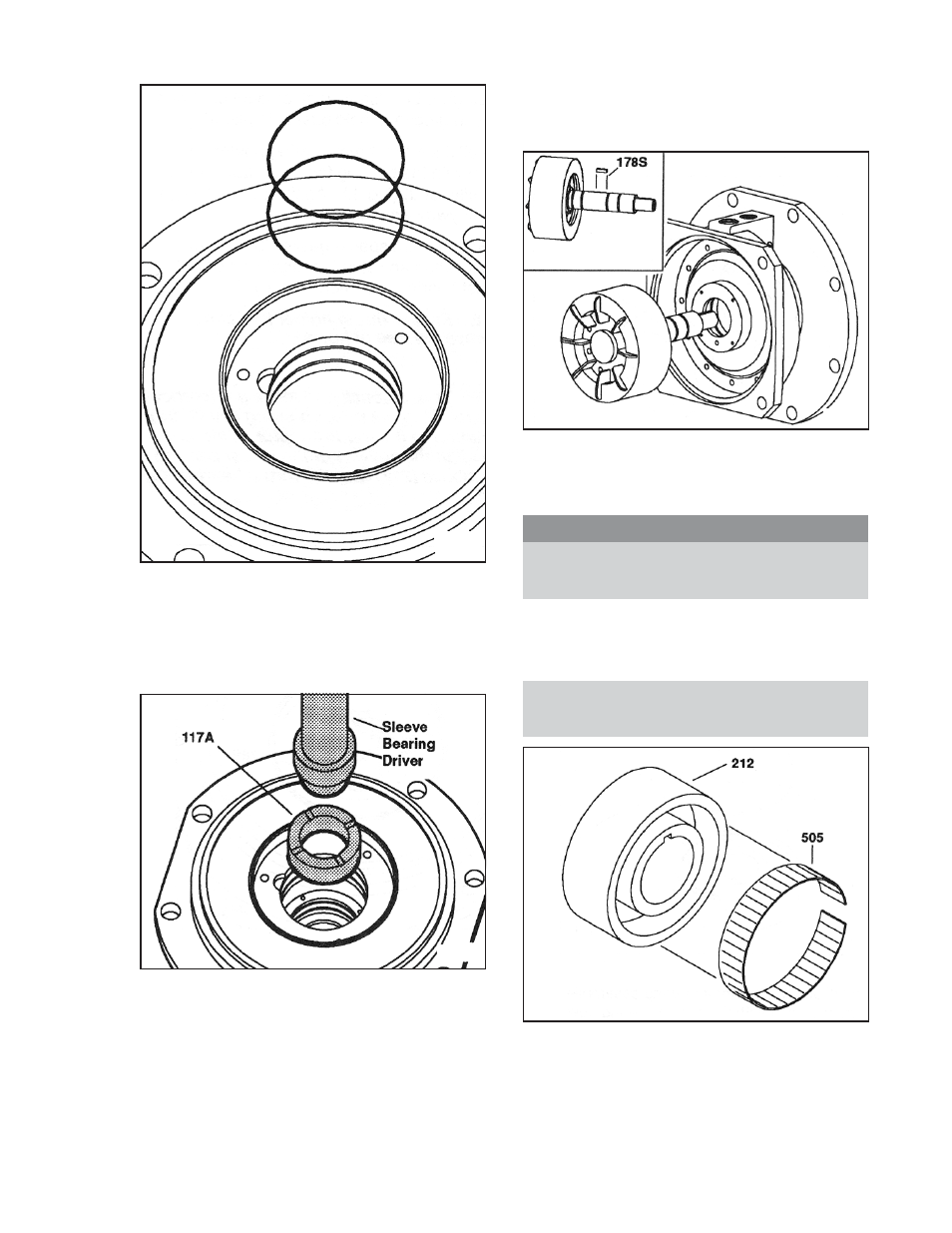

12. Install outboard stationary sleeve bearing (117A)

(Fig. G). The anti-rotation slot in bearing (117A)

must line up with anti-rotation pin (445B) in

outboard end of frame adapter (108). Press

outboard stationary sleeve bearing (117A) in by

hand using sleeve bearing driver.

13. Install thrust bearing holder key (178S) into driven

shaft (122A) (Fig. H). Use a small amount of

O-ring lube in keyway to hold key in place.

14. With partially assembled rotating assembly

positioned as shown install into partially built

frame adapter assembly (Fig. H).

15. Carefully roll adapter with rotary assembly onto

face of rotary assembly (impeller end of shaft

facing up).

s

!

WARNING

Ensure rotary assembly does not fall out of

adapter. This could cause bodily injury and

damaged parts.

16. Install a tolerance ring (505) into both thrust

bearing holders (212) (Fig. I). Shoulder tolerance

ring against face in thrust bearing holder.

NOTE: It may be necessary to form ring with your

fingers to insure good contact between ring OD

and holder bore.

3296 M Group 6/05

41

Fig. H

Fig. I

Fig. G

Fig. F