Caution – Goulds Pumps 3296M - IOM User Manual

Page 37

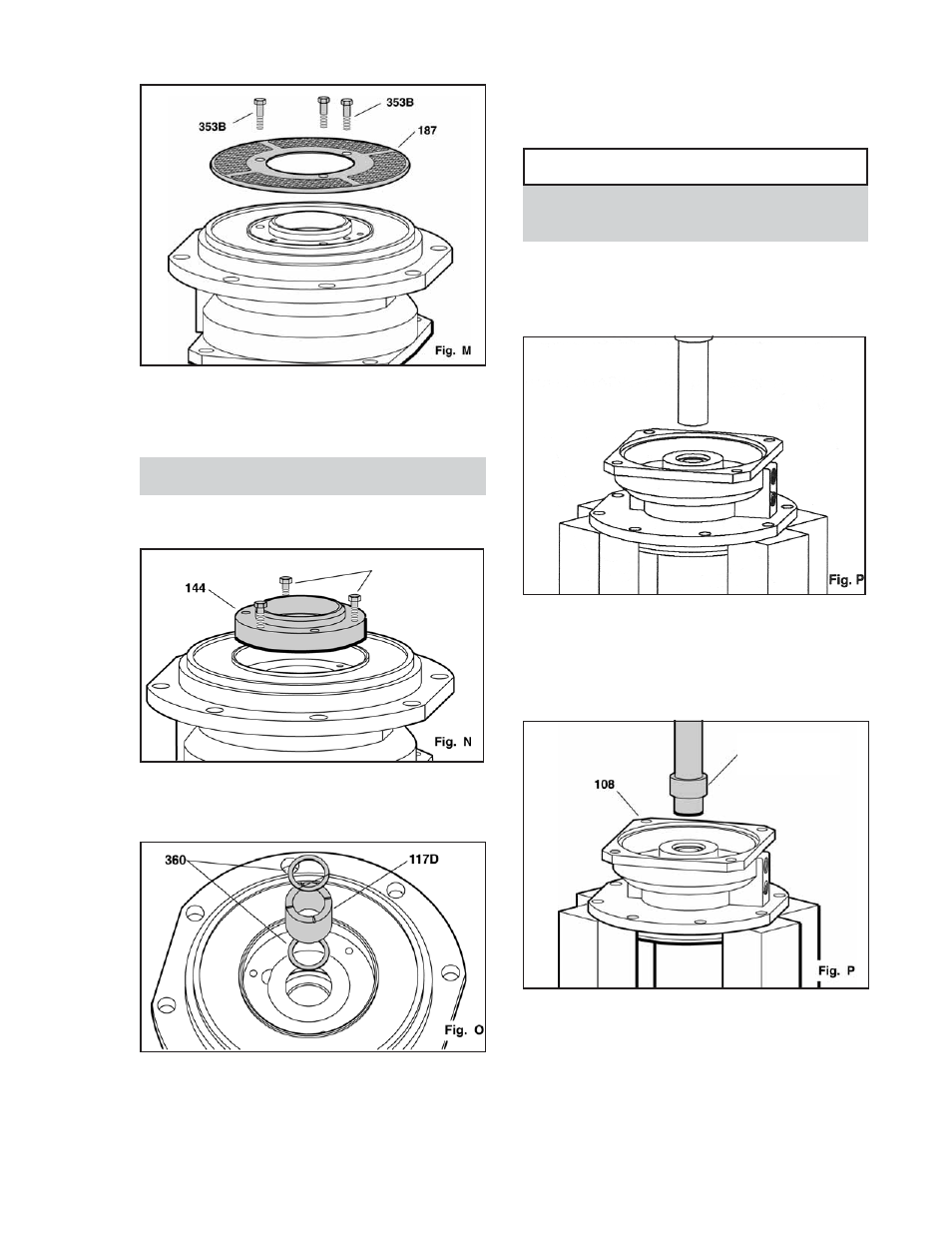

22. Place wear ring jacking screws in threaded jacking

screw holes in wear ring (144) as shown. Tighten

bolts evenly and in sequence until wear ring (144)

can be removed (Fig. N).

NOTE: Do not over tighten jacking bolts. Tighten

until snug and move to next one in sequence.

23. Remove wear ring (144) and stationary bearing

key (178K) (Fig. N).

24. Remove inboard rotary sleeve bearing (117D) and

two spacer gaskets (360) (Fig. O). Discard

gaskets.

25. Set frame adapter (108) on blocks, impeller side

down, and place clean cloth underneath as shown

to absorb impact when bearings drop (Fig. P).

l

!

CAUTION

The bearing material is extremely brittle. Take

every precaution necessary to avoid shock to the

bearings.

26. Press out thrust bearing assembly (212) and

inboard stationary sleeve bearing (117B) using

hand pressure and sleeve bearing driver oriented

as shown (Fig. P).

27. Set aside thrust bearing assemblies (212) and

outboard stationary sleeve bearing (117B).

28. Press outboard stationary sleeve bearing (117A)

out of frame adapter (108) using sleeve bearing

driver oriented as shown (Fig. Q).

29. Invert frame adapter (108), impeller end up, and set on

bench. Remove outboard stationary O-rings (496A)

and inboard stationary O-rings (496B). Discard

O-rings (Fig. R).

3296 M Group 6/05

33

Jacking Screws

Sleeve Bearing

Driver