Shaft sleeve (126) installation, Impeller (101) installation, Warning – Goulds Pumps 3100 - IOM User Manual

Page 41: Casing (100) installation

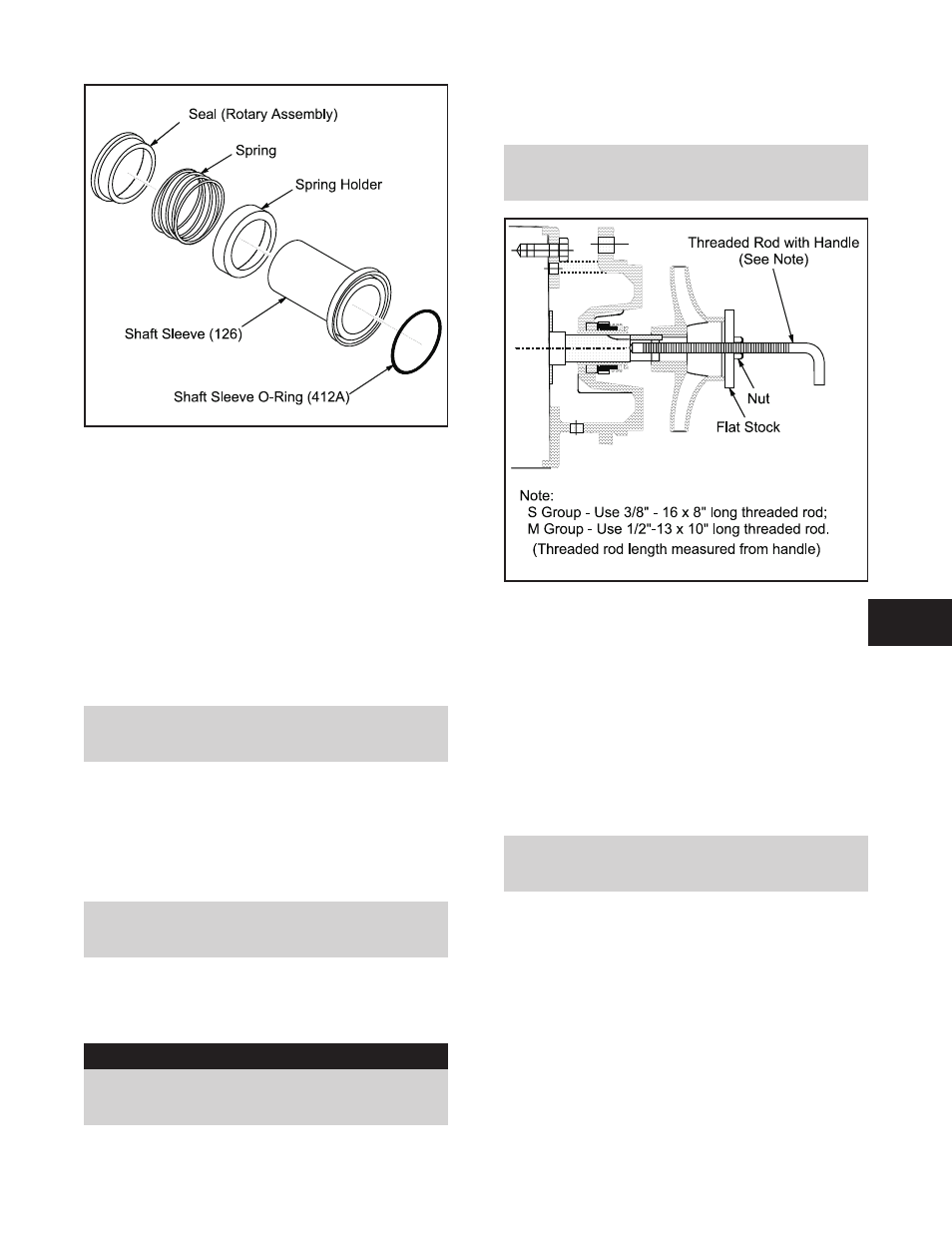

14. Install spring over shaft sleeve (126) against

spring holder.

15. Install seal (rotary assembly) onto shaft sleeve

(126) until face of seal is flush to open end of

sleeve.

SHAFT SLEEVE (126) INSTALLATION

16. Lubricate sleeve O-ring (412A) with the same

lubricant used for mechanical seal parts

(Table 6).

17. Install O-ring (412A) into O-ring groove on shaft

sleeve (126).

NOTE: Anti-galling compound can be applied

to shaft sleeve bore to aid in future

disassembly.

18. Install shaft sleeve (126) on motor shaft with

mechanical seal face towards the motor.

IMPELLER (101) INSTALLATION

19. Place impeller key (178) in keyway on motor

shaft.

NOTE: Impeller Key (178) will extend beyond

end of motor shaft at this point in the

reassembly procedure.

20. Apply anti-galling compound to motor shaft

outside diameter to aid in assembly and future

disassembly.

▲

!

WARNING

Wear heavy work gloves when handling

impeller (101) as sharp edges may cause

physical injury.

21. Align keyway in impeller (101) with impeller key

(178) on motor shaft. Install impeller (101) onto

shaft far enough to engage impeller nut (304).

NOTE: Do not force impeller onto shaft. If fit

is tight between motor shaft and impeller bore,

use puller (Fig. 30).

22. Lubricate impeller nut O-ring (412A) with the

same lubricant used for mechanical seal parts

(Table 6).

23. Install O-ring (412A) into O-ring groove on

impeller nut (304).

24. Thread impeller nut (304) into motor shaft.

Tighten impeller nut (304)

CASING (100) INSTALLATION

25. Install casing O-ring (412K) into casing (100).

NOTE: Anti-galling compound can be applied

to outside diameter of the seal chamber (184)

to aid in future disassembly.

26. Install casing:

M-Group - use hex cap screws (370).

S-Group - use hex cap screws (370) on 8-inch

pump, or hex nuts (425) and studs (356A) on

6-inch pump.

27. Tighten bolts in a criss-cross pattern to values

indicated in Table 7.

3100 IOM 1/97

33

6

Fig. 29

Fig. 30