Reassembly, Shaft sleeve (126), Motor adapter (504) - m group only – Goulds Pumps 3100 - IOM User Manual

Page 39: Motor inspection, Table 5 motor inspection specifications

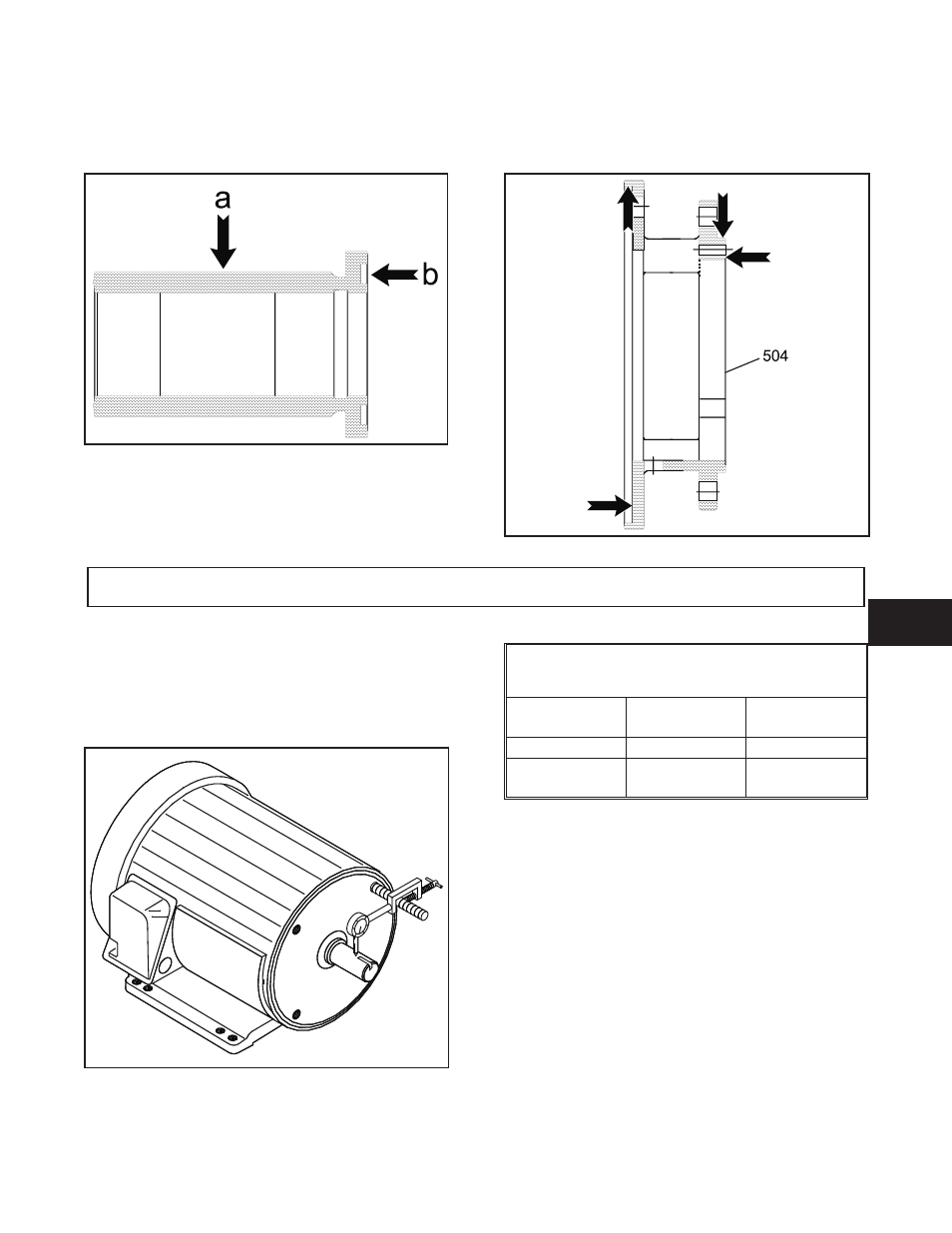

SHAFT SLEEVE (126)

1.

Check shaft sleeve surface for grooves and/or

pitting (Area “a” in Fig. 24). Replace if any are

found.

2.

Inspect O-ring groove on face of shaft sleeve.

(Area “b” in Fig. 24). Surface should be free of

pits, grooves and scratches.

MOTOR ADAPTER (504) - M GROUP ONLY

1.

Check motor adapter (504) for cracks or

excessive corrosion damage. Replace if any of

these conditions exist. (Fig. 25)

REASSEMBLY

MOTOR INSPECTION

1.

Check shaft runout. Rotate shaft by hand 360

degrees (Fig. 26). If total indicator reading (TIR)

is greater than the values indicated in Table 5,

check the motor for cause of the runout

(possible bent shaft).

Table 5

Motor Inspection Specifications

Motor Size

Shaft Runout

(TIR)

Shaft End Play

140JM-250JM

.002

.004

280JM-320JM,

364TZC

.003

.006

2.

Check shaft endplay on the motor (Fig. 27).

Move shaft forward and backward by hand,

noting indicator movement. If movement is

greater than values indicated in Table 6, check

the motor for cause of looseness (possible

failed motor bearings).

3100 IOM 1/97

31

6

Fig. 24

Fig. 25

Fig. 26