Goulds Pumps 3100 - IOM User Manual

Page 34

MAINTENANCE ON MECHANICAL SEAL

4.

Place sling from hoist through webbing of motor

adapter (504) or seal chamber/adapter (184).

5.

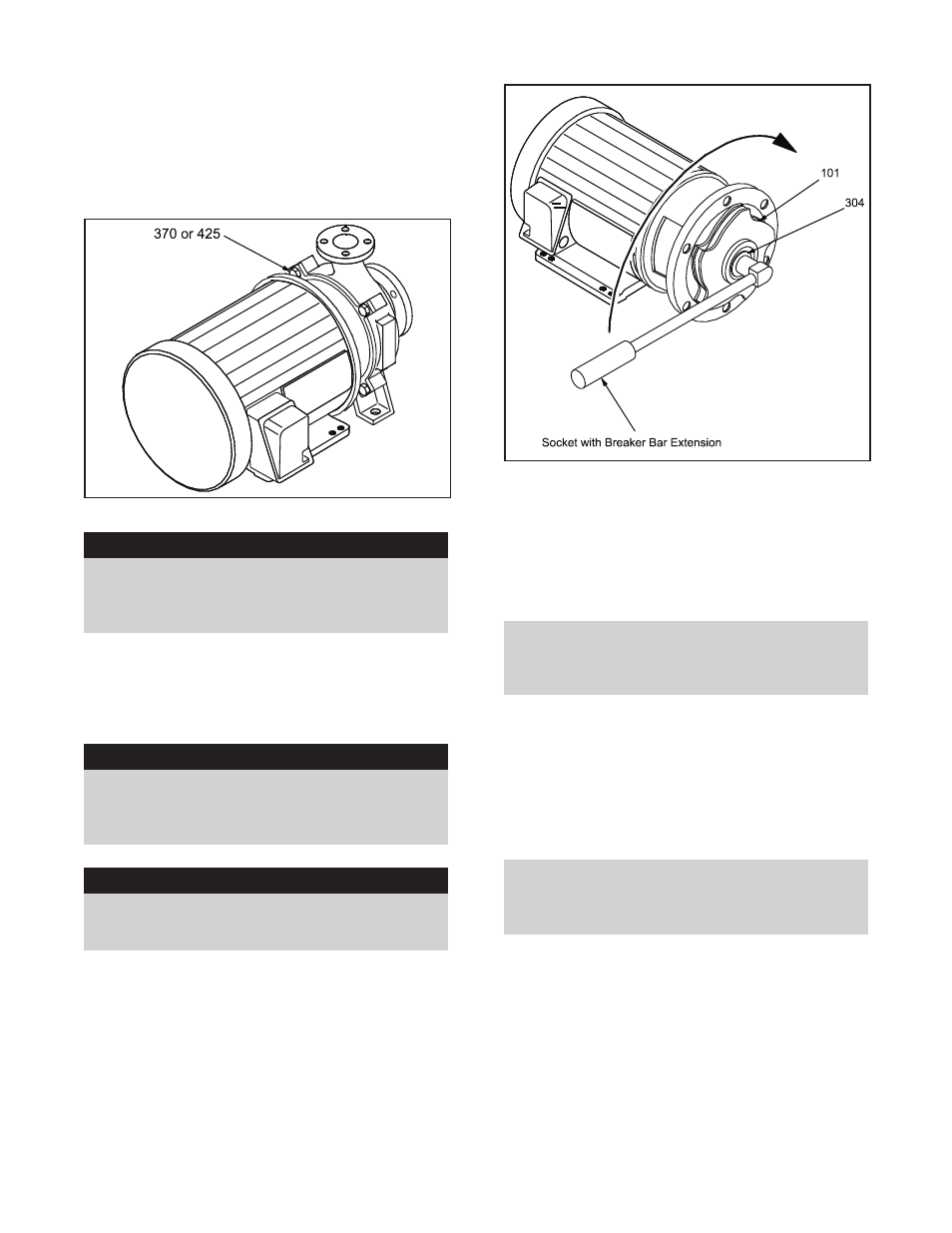

Remove casing bolts (370) or casing nuts (425),

then slide back pull-out assembly away from

casing (Fig. 12).

▲

!

WARNING

Never apply heat to remove parts. Use of heat

may cause an explosion due to trapped fluid,

resulting in severe physical injury and

property damage.

6.

Remove casing O-ring (412K) and discard.

(Replace with new O-ring during reassembly).

REMOVAL OF IMPELLER

▲

!

WARNING

Never apply heat to remove parts. Use of heat

may cause an explosion due to trapped fluid,

resulting in severe physical injury and

property damage.

▲

!

WARNING

Wear heavy work gloves when handling

impeller (101) as sharp edges may cause

physical injury.

7.

Rotate impeller (101) clockwise (viewed from

impeller end of shaft) raising breaker bar off

work surface to the 9 o’clock position.

8.

Quickly turn breaker bar clockwise (viewed from

impeller end of shaft) until the breaker bar

handle impacts against the work bench and

loosens the impeller nut (304) (Fig. 13).

9.

Remove impeller nut (304) (Fig. 13).

10. Remove O-ring (412A) from impeller nut (304)

and discard. (Replace with new O-ring during

reassembly.)

11. Remove impeller (101) from motor shaft.

NOTE: It may be necessary to use a puller.

Puller must be placed under vanes so as not

to damage the impeller. Protection for motor

shaft should also be provided.

12. Remove and discard sleeve O-ring (412A).

(Replace with new O-ring during reassembly.)

REMOVAL OF SLEEVE/ MECHANICAL

SEAL (M GROUP)

13. Remove shaft sleeve (126) and rotary portion of

mechanical seal (383) (Fig. 14).

NOTE: Mechanical seal (383) is mounted to

shaft sleeve (126). Rotary portion of

mechanical seal must be removed by sliding it

off the sleeve.

26

3100 IOM 1/97

Fig. 12

Fig. 13