Inspections, Removal of motor adapter - m group, Casing (100) – Goulds Pumps 3100 - IOM User Manual

Page 36: Impeller (101)

19a. If required, remove mechanical seal stationary

seat from seal chamber (184).

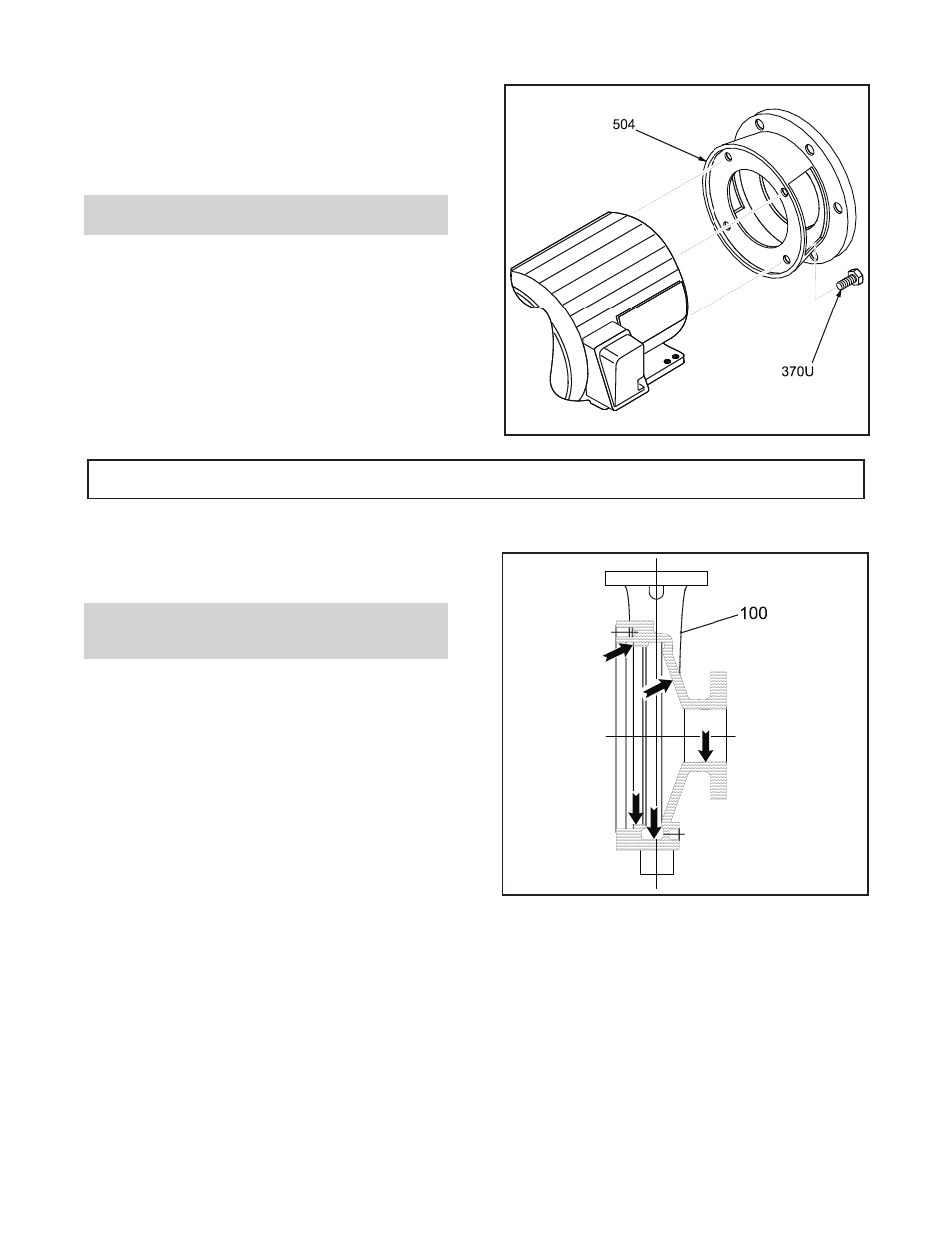

REMOVAL OF MOTOR ADAPTER -

M GROUP

NOTE: Removal of motor adapter (504) is only

required if repairing or replacing the motor.

20. Remove hex cap screws (370U) from motor.

21. Remove motor adapter (504)(Fig. 18).

INSPECTIONS

Model 3100 parts must be inspected to the following

criteria before they are reassembled to ensure the

pump will run properly. Any part not meeting the

required criteria should be replaced.

NOTE: Clean parts to remove oil, grease, or

dirt. Protect machine surfaces against

damage during cleaning.

CASING (100)

The casing (100) should be inspected for excessive

wear or pitting. It should be repaired or replaced if it

exceeds the following criteria (Fig. 19)

1.

Localized wear or grooving greater than 1/8”

(3.2 mm) deep.

2.

Pitting greater than 1/8” (3.2 mm) deep.

3.

Inspect case O-ring seat surface for

irregularities.

IMPELLER (101)

1.

Inspect wear ring surface for signs of pitting

2.

Inspect front and back wear ring clearance per

Table 3 (Fig. 20).

28

3100 IOM 1/97

Fig. 19

Fig. 18