3 self test mode, 4 error recovery – Pulsafeeder Pulsar ECA NEMA7 User Manual

Page 20

14

5.3 Self Test Mode

The ECA has a diagnostic test mode which can be used to verify performance and troubleshoot

problems. To initiate the self-test:

1. Remove power from the ECA, and remove the top cover.

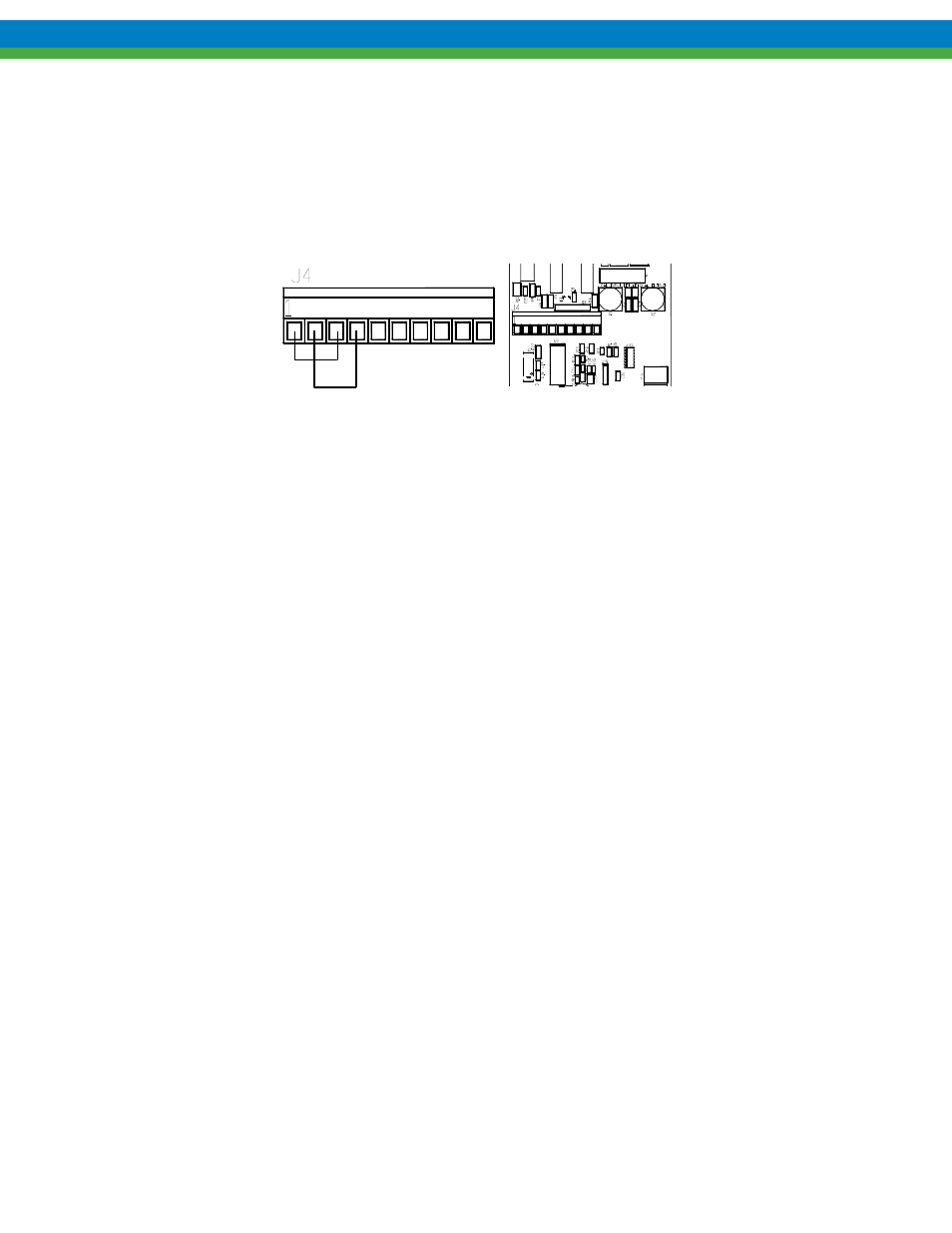

2. Disconnect any field wires attached to J4, and connect Analog Out to Analog In. (jumper J4-1 to

J4-3 and J4-2 to J4-4).

Figure 11

3. Press and hold the WHITE button.

4. Apply power to the ECA. The ECA will enter the self-test mode and perform the following tests:

1. Calibrates mechanical zero position, if necessary.

d) Drives to the 0% stroke position, testing the motor drive and the encoder. Both LED’s

will blink if the zero calibration fails.

e) Pauses for 30 seconds, then confirms that the analog output and the analog input are

correct. Sets trouble code 22 if analog ports do not agree.

f) Drives to the 100% stroke position, testing the motor drive and the encoder. Sets the

trouble code to 13 if the 100% position is not attainable.

g) Pauses for 30 seconds, then confirms that the analog output and the analog input are

correct. Sets trouble code 23 if analog ports do not agree.

h) Confirms that the motor thermistor is reading in correct range. Sets trouble code 24 if

thermistor readings are outside specifications.

i) Sets trouble code 33 to indicate test passed.

5. Turn power off to the ECA, and remove the jumpers installed in step 2. Re-connect field wires.

6. Replace the cover (see Section 4.3) and return power to the ECA.

5.4 Error

Recovery

In cases of abnormal operation, the following procedure is recommended:

1. First, check all power and process connections to ensure all wiring is secure and properly

connected.

2. Check the internal connections within the ECA, ensure that the molded plugs from the stroke

adjustment motor and encoder are secure.

3. Perform a Factory Re-initialization, as described in Section 4.9. This will also force a new

mechanical zero calibration to be performed. The pump motor should be operating during this

process as the ECA will adjust stroke to re-locate the zero position. Ensure that it is safe to

operate the pump during this step.

4. Perform a new analog input signal calibration as per Section 4.7.1.

5. Perform a new analog output signal calibration as per Section 4.7.3.