3 analog output signal calibration – Pulsafeeder Pulsar ECA NEMA7 User Manual

Page 17

11

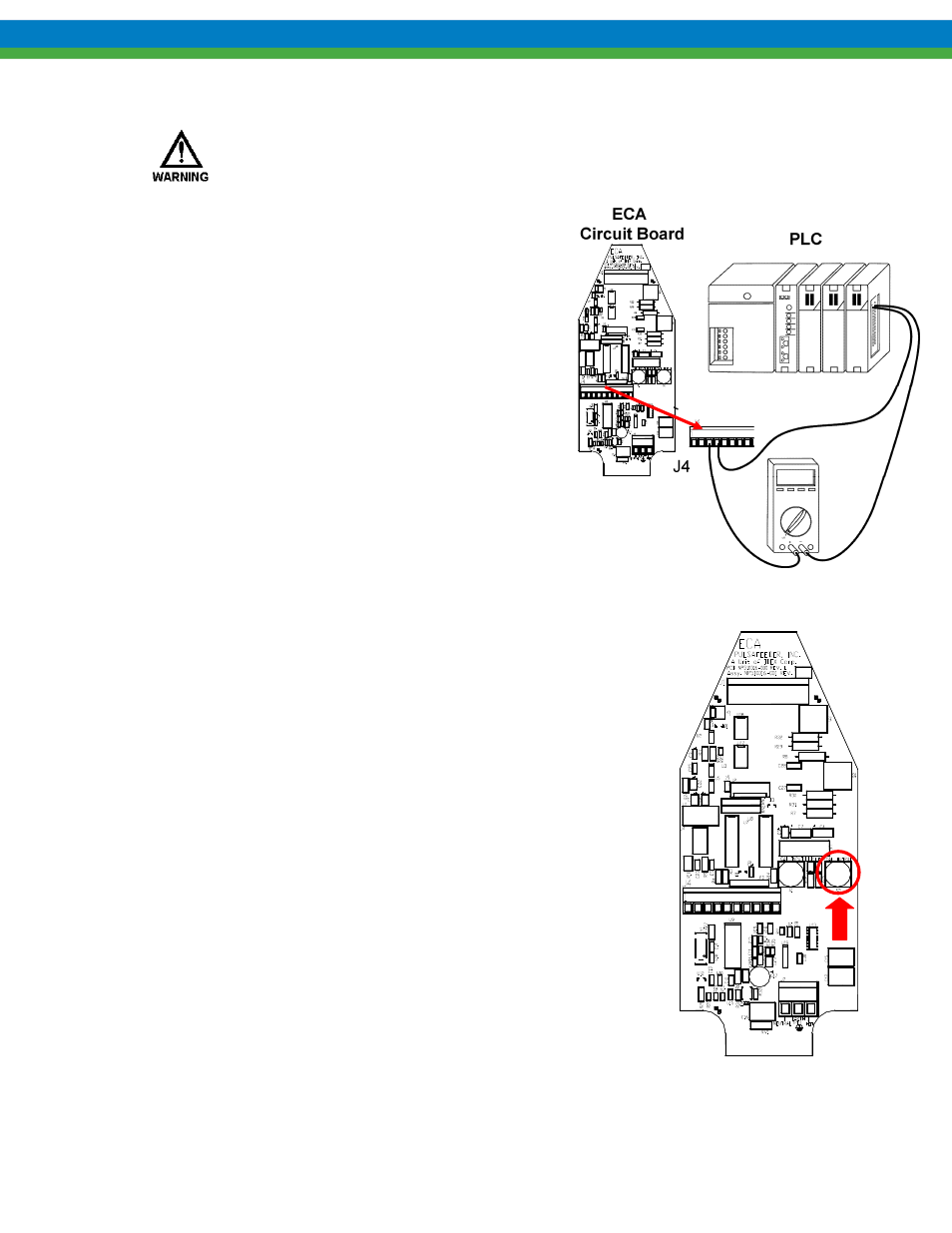

4.7.3 Analog Output Signal Calibration

T

HIS PROCEDURE REQUIRES REMOVAL OF THE ENCLOSURE COVER

.

T

HIS SHOULD BE

DONE ONLY IF THE AREA IS KNOWN TO BE NON

-

HAZARDOUS

.

To calibrate the analog output, you need to attach

an ammeter to the output circuit, or have the ECA

wired to the PLC or other device. It is

recommended that you calibrate to the actual

remote equipment and set the analog output values

at whatever is required by that equipment. For

example, the ECA output can be adjusted at the

zero point so that the screen on the PLC system

reads zero %, regardless of the actual mA value of

the signal. The ECA will not actuate to change

stroke length during this process.

Figure 9

1. With the cover removed and power supplied to the ECA, press the

black Output Cal pushbutton. The Cal Output LED will blink

slowly and current output will be set to the present analog out low

calibration value. (4 mA factory default)

2. Press and hold the white Input Cal pushbutton to increase current

output until the desired low setpoint is reached. Release and press

again to decrease current output. Current will change in steps of

approximately 0.02 mA, at a rate of 20 steps per second.

3. Press the black Output Cal pushbutton. The Cal Output LED will

blink rapidly and current output will be set to the present analog

out high calibration value. (20 mA factory default)

4. Press and hold the white Input Cal pushbutton to decrease current

output until desired high setpoint is reached. Release and press

again to increase current output. Current will change in steps of

0.125 mA at a rate of 20 steps per second.

5. Press the black Output Cal pushbutton. The Cal Output LED will

extinguish, unless the minimum span of 2.0 mA is violated, then

the ECA will return to step 1 above.

6. Replace the cover (see Section 4.3) and return power to the ECA.

Figure 10