7 system calibration, 1 analog input signal calibration, 2 analog input signal loss – Pulsafeeder Pulsar ECA NEMA7 User Manual

Page 16

10

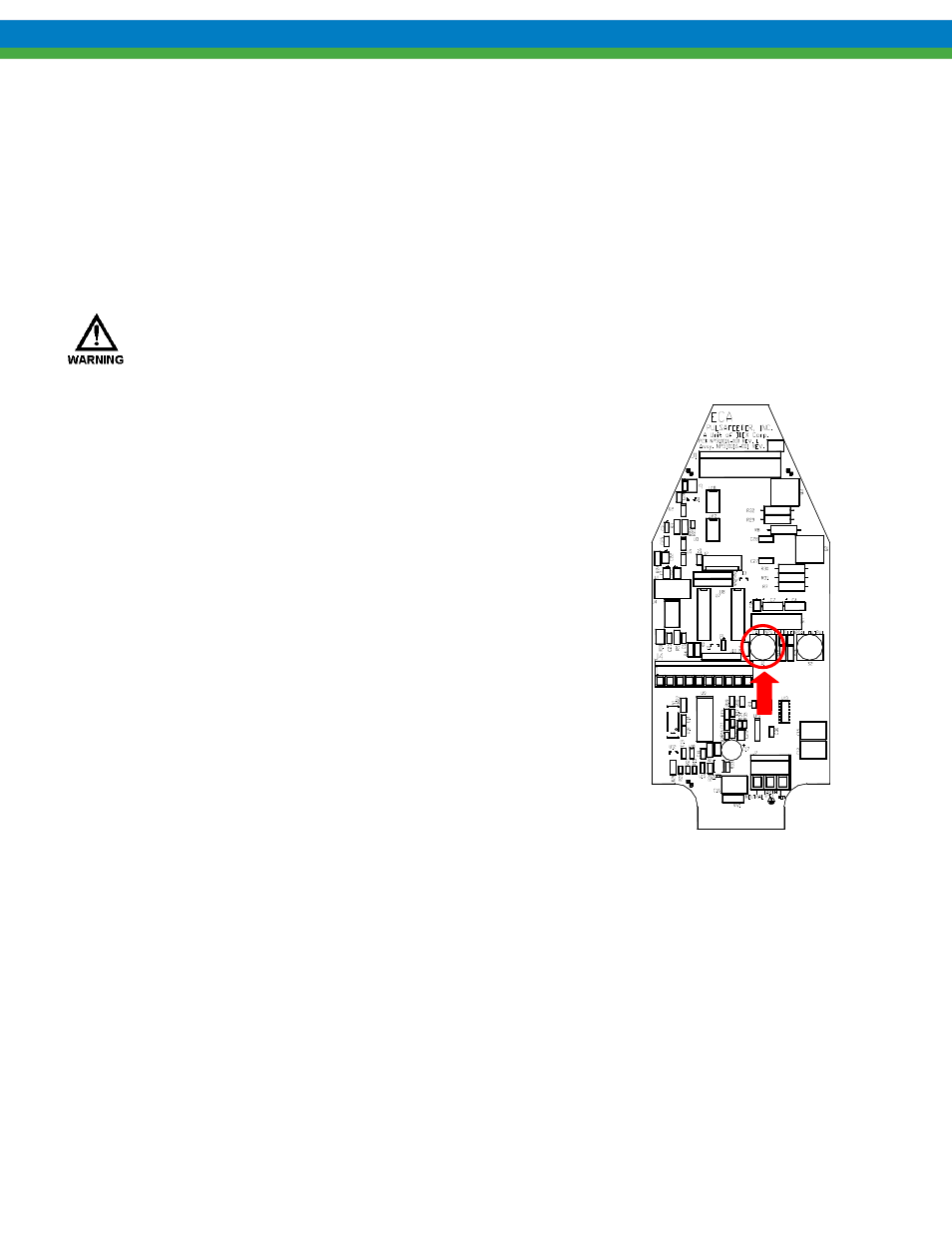

Figure 7

4.7 System

Calibration

4.7.1 Analog Input Signal Calibration

The analog input signal should be calibrated to each system. To perform a calibration, the signal-

generating device (e.g., PLC) must be powered up, wired to the ECA and capable of altering its

output from the minimum to the maximum signal. Note that the minimum span, or difference

between low and high values, is 2.0 mA. The ECA will not actuate to change stroke length during

this process.

T

HIS PROCEDURE REQUIRES REMOVAL OF THE ENCLOSURE COVER

.

T

HIS PROCEDURE

SHOULD BE PERFORMED ONLY IF THE AREA IS KNOWN TO BE NON

-

HAZARDOUS

.

1. With the cover removed and power supplied to the ECA, press and

release the white Input Cal pushbutton. The Cal Input LED will blink

slowly, indicating the ECA is ready to accept the low (0% stroke)

analog input value.

2. Send the low analog signal to the ECA (generally 4 mA) from the

signal-generating device (e.g., PLC). It is highly recommended that

you use the actual signal the ECA will be receiving during calibration.

3. When the low analog input value has stabilized (allow 10-15 seconds),

press the white Input Cal pushbutton to accept it as the 0% flow

analog signal value. The Cal Input LED will now blink rapidly.

4. Send the desired analog high signal (generally 20 mA).

5. When the high analog input value has stabilized (allow 10-15

seconds), press the white Input Cal pushbutton to accept it as the high

(100% stroke) analog signal value. The Cal Input LED will

extinguish, unless the minimum span of 2.0 mA is violated, then the

ECA will return to step 1 above.

Reverse-acting calibration is accomplished by input of a high signal

(i.e., 20 mA) as the low (0% stroke) analog input value, and a low

signal (i.e. 4 mA) as the high (100% stroke) analog signal.

6. Replace the cover (see Section 4.3) and continue with the output

calibration if that function is being utilized.

Figure 8

4.7.2 Analog Input Signal Loss

A failure of the analog input signal is detected if the input signal falls below the calibrated 0%

stroke signal by 0.3 mA. For example, if the ECA is calibrated with a range of 4-20 mA and the

signal falls to 3.6 mA then a failure will be logged. If the calibrated 0% stroke signal is 0.3 mA or

less, no signal loss failure will be generated. Input signals above the calibrated 100% stroke signal

are simply ignored, the stroke position will be driven to 100% and no error condition occurs.

In the event of a loss of analog signal or an abnormally low signal, the ECA will drive to the zero

stroke position. The ECA will recover once a valid analog signal is present and resume control to

the appropriate setpoint.

Jumper J6 should be left in the factory default position. Do not change the position of this jumper.