Make-up valve, Bypass valve – Pulsafeeder Pulsa Series 200-680C User Manual

Page 11

11

Hydraulic Make-up Valves

To adjust the valve to a lower

3.

Restricted flow to the

Figure 12

Hydraulic make-up valves are

inlet strainer is plugged,

designed to maintain the

To check pressure setting it is

or someone closes an

correct volume of oil in the

necessary to install a gauge in

inlet valve thereby

hydraulic system between the

the discharge line between

restricting flow of fluid to

piston and the diaphragm.

the pump and a shut off valve.

the pump, the diaphragm

No adjustment or attention is

With the pump operating at

is then unable to follow

required, provided the oil is

maximum stroke a gradual

movement of the

clean and free of moisture

closing of the shut off valve

plunger. The vacuums

and chemical contamination.

will cause the bypass valve to

created between the

Since the valve operates only

reach its cracking pressure

diaphragm and the

occasionally and with very

which will be observed on the

plunger upset the make-

little movement it is not

gauge. When the bypass

up valve allowing oil to

considered a normal

valve is set for maximum

replace the vacuum

replacement item in a service

pump operating pressure

condition. This excess

schedule. If the valve is

(shown on nameplate),

oil will be displaced

replaced because of

cracking pressure is slightly

through the hydraulic

corrosion or fouling be sure

above maximum operating

bypass valve on the

tape or sealant is used on the

pressure so that it does not

discharge stroke of the

pipe threads to assure an air

weep during normal pump

plunger. Undersized

tight seal.

operation. Dead head

(restrictive) piping must

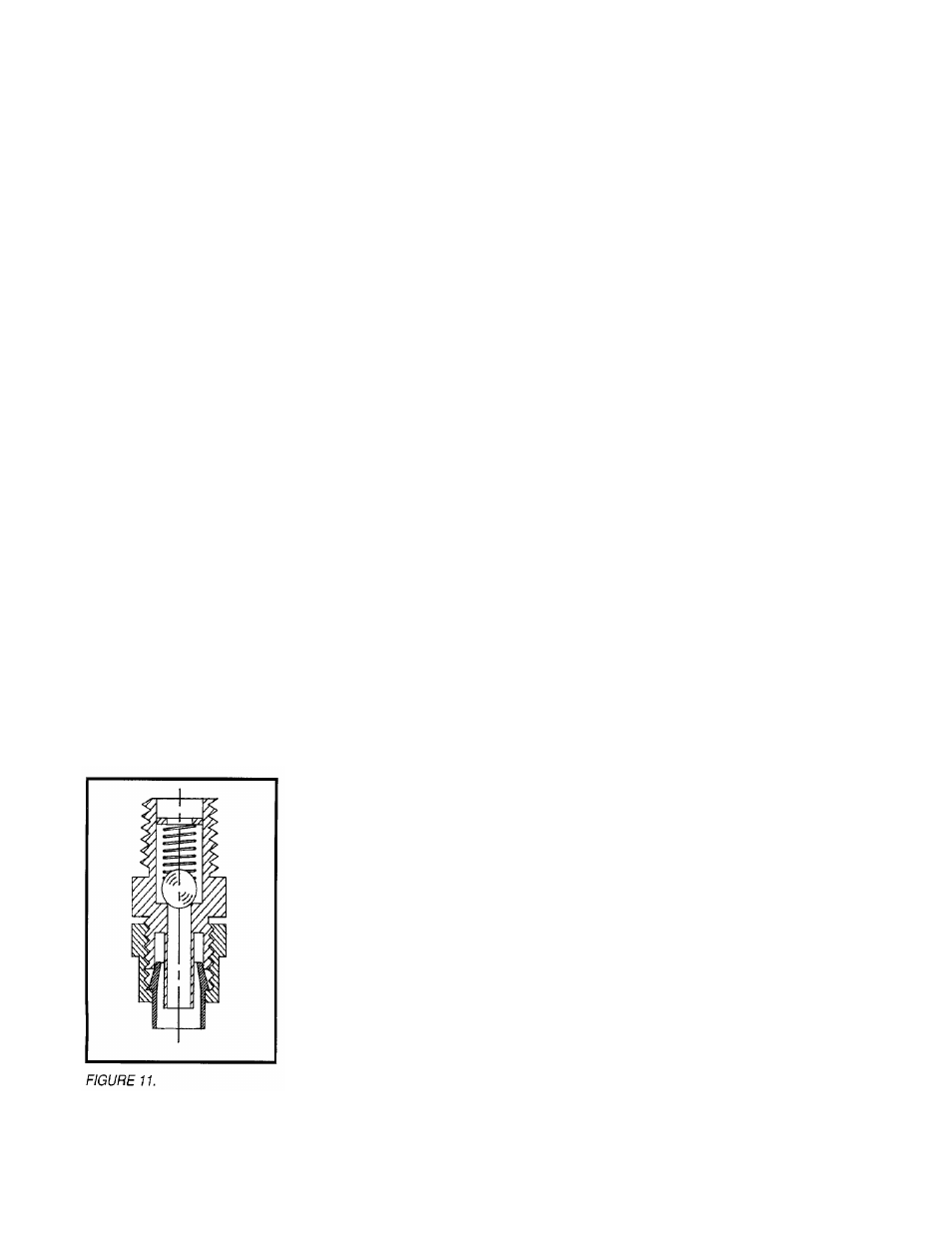

Hydraulic Bypass Valve

considerably higher than

page 5).

The bypass valve is an

large piston, fast stroke rate

Any unusual condition in the

adjustable spring loaded

models, so the internal

system which prevents free

valve. It is designed to protect

bypass valve should not be

movement of the diaphragm

the pump against excessive

considered a safety valve for

will cause a recirculating

hydraulic pressure. The valve

protection of the process

condition between the make-

is factory set to the setting

piping and instrumentation. A

up valve and the hydraulic

specified on the specification

separate process relief valve

bypass valve. Continuous oil

data sheet or set to allow

should be used for this

recirculation against the

operation at the maximum

purpose.

bypass valve will eventually

pump pressure, indicated on

cavitate the hydraulic prime

the pump nameplate, without

It is unusual for a hydraulic

plus introduce unnecessary

weeping.

bypass valve to operate

load conditions within the

set pressure, turn counter-

pump causing the make-

clockwise.

up valve to operate. If an

dumping pressure can be

be avoided (see "Piping"

cracking pressure on some

during normal pump

pump mechanism.

operation. The following

conditions will cause valve

operation:

1.

Excessive pressure

buildup in the process

which the pump is

injecting into.

2.

A plugged discharge line

or someone shutting off

a valve in the discharge

line while the pump is

operating.