Repriming the hydraulics – Pulsafeeder Pulsa Series 200-680C User Manual

Page 10

10

13. Diaphragm can be

3.

Connect inlet piping.

removed from the

4.

With discharge line

8.

Add PULSAlube oil to

reagent head by applying

bypassed around

front and rear oil

air pressure to one of the

process or to drain, start

reservoirs to bring oil

valve ports while

motor and prime reagent

level up to top of

blocking the other. Be

head.

partition.

sure diaphragm is

5.

Set stroke length

9.

After pump has run for

directed away from

adjustment to maximum

several hours, again

personnel so that it does

stroke.

check for any last traces

not strike the body when

6.

If not already lose,

of air at the bypass valve.

being expelled from the

counting turns, loosen

head.

the hydraulic bypass

Check Valve

14. Diaphragms which are

valve located at the top

punctured or show

of the hydraulic system

evidence of tearing or

to atmosphere and any

Operating experience on

abrasion at the sealing

air present will vent back

thousands of installations has

edge should be

into the gearbox oil

indicated that many pump

replaced. If diaphragm

reservoir as the

troubles have to do with check

shows evidence of

automatic make-up valve

valves. Problems usually

hardening so as to be

fills the piston/diaphragm

stem from (a) an

non-flexible it should be

chamber. Air bubbles

accumulation of trash

replaced.

will be evident at the vent

between the valve and seat,

Repriming Hydraulic

head in back of return

seating surfaces, (c) erosion

Systems on HYDRACONE

spring.

from high velocity flow, or (d)

Models

7.

When last traces of air

normal physical damage after

1.

Reassemble diaphragm

retighten the bypass

and reagent head,

valve the same number

When inspecting the valves,

tightening all bolts

of turns or to a desired

separate the assembly and

securely and evenly.

setting using a pressure

examine the components for

2.

Reassemble valve

gauge in the process

wear, damage or

housing, valves, seats

line. Approximately a 1/2

accumulation of solids. A ball

and seat gaskets and

turn more after process

valve seat should have a

take care in inserting

pressure setting has

sharp 90 edge, free of any

gaskets that they are

been reached will seat

nicks or dents. Hold the ball

properly placed. Tighten

valve. The valve can be

firmly on the seat and

securely.

set higher if desired but

examine against a light. If

hole, top center of pump

(b) corrosion which damages

have been expelled

extended service.

do not exceed MAX.

light is visible between the two

OPERATING

then replace the seat and/or

PRESSURE indicated on

ball.

the nameplate.

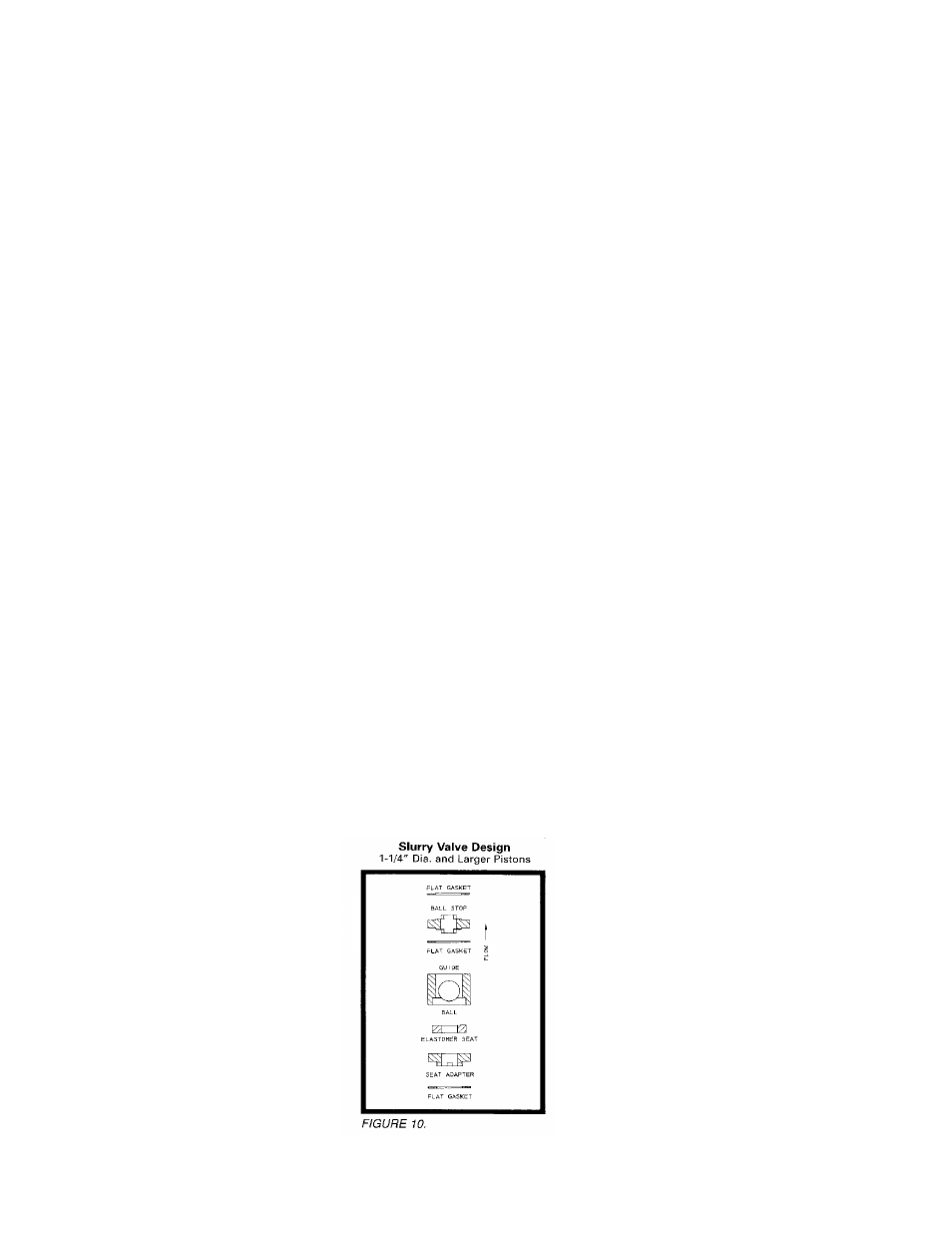

Figure 7, 8, 9 and 10

o

When reassembling after

cleaning or replacement be

sure to use new seals.