Dc drive configuration, Jumpers, Potentiometer descriptions – Pulsafeeder Pulsa Series Cruise Control User Manual

Page 14: Dc d, Rive, Onfiguration, 1 jumpers, 2 potentiometer descriptions

8. DC

Drive

Configuration

The Control Techniques DC Drive is properly configured for your application during assembly. The following

information is for reference only.

Some panels may be supplied with an alternate drive to conform to the user’s specification. If your

panel is so equipped, please refer to the appropriate manufacturer’s literature for this information.

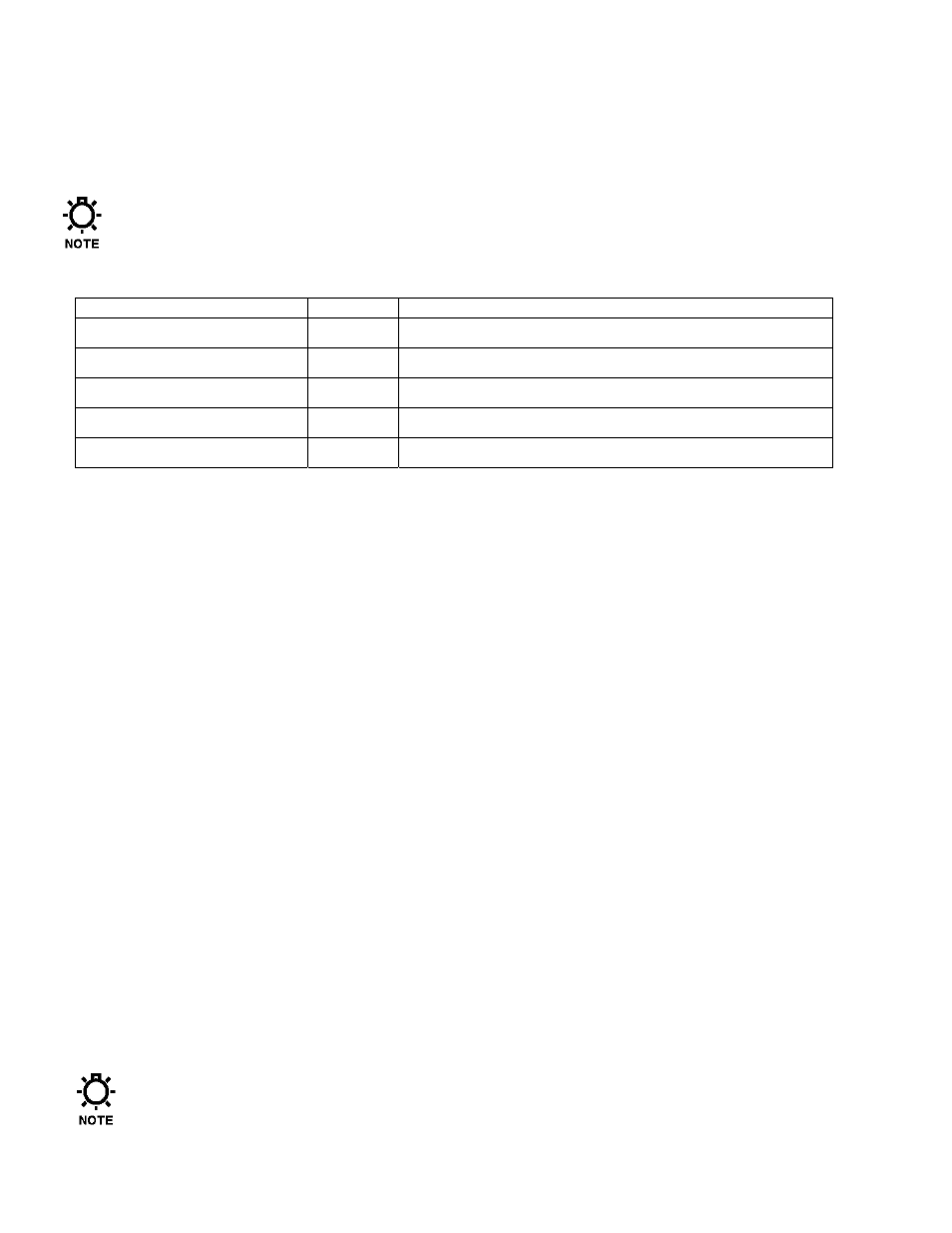

8.1 Jumpers

Description Jumper

Position

Input Voltage

JP11

A-E and B-D (120 VAC) or A-C and B-C (240 VAC)

Speed Feedback Selector

JP4

ARM (Armature) or TACH (Tachometer)

Armature Voltage Level

JP8

LOW (90 VDC) or HI (180 VDC)

Current Feedback Range

JP9

No Jumper (2.6A) A (5.5A) B (7.5A)

Tachometer Feedback Range

JP3

LOW (6.5-17.4 VDC) or HI (60-160 VDC)

(Note: feedback range is based on tachometer output at maximum motor speed)

8.2 Potentiometer

Descriptions

1. Acceleration Time (ACCEL) and Deceleration Time (DECEL). Adjust the ACCEL and DECEL

potentiometers clockwise to increase the linear acceleration and deceleration times (.3-30 seconds).

2. Maximum Speed (MAX. SPEED) and Minimum Speed (MIN. SPEED). These potentiometers adjust the

maximum speed (70-120% of motor base speed) and minimum speed (0-30% of maximum speed setting)

at which the motor will run.

3. Speed Loop Offset (OFFSET SPEED). This potentiometer is used to zero out any offsets in the speed

loop amplifier. With the door mounted speed potentiometer and drive minimum speed potentiometer

(MIN. SPEED) set to zero, adjust the OFFSET SPEED potentiometer so any remaining motor rotation is

eliminated.

4. Speed Signal Follower Gain (SPEED REF. GAIN). The Speed Signal Follower Gain should be adjusted

so the motor is at its rated voltage/speed when the door-mounted potentiometer is at its full clockwise

position.

5. Signal Follower Zero Bias (ZERO BIAS). The Signal Follower Zero Bias potentiometer should be

adjusted so the motor is at zero speed when the minimum current reference input signal (4mA) is applied.

6. Current Signal Follower Gain (CURRENT REF GAIN). The Current Signal Follower Gain should be

adjusted so the motor is at its rated voltage/speed when the maximum current reference input signal

(20mA) is applied.

7. Internal Resistance Compensation (IR COMP). The IR compensation potentiometer is used to overcome

the motor’s natural tendency to slow down as the load increases. If the motor slows down excessively as

it is loaded, adjust the IR COMP potentiometer clockwise. The speed of the motor will oscillate or ‘hunt’

if the IR COMP potentiometer is adjusted too far clockwise. If this pulsing occurs, adjust the IR COMP

potentiometer counterclockwise until the motor speed stabilizes.

Refer to Control Techniques Focus 3

™

User Guide page 20 for additional information.

10