Ke2 evaporator efficiency, Figure 4 - coil sensor placement, Additional inputs – Nor-Lake Enviro-Control IOM User Manual

Page 5

KE2 EvaporatorEfficiency

Installation Instructions

holder. Depress slightly and turn 1/4 turn counterclockwise to

remove. Replace by depressing slightly and turning 1/4 turn

clockwise. Do not overtighten.

The board uses a pluggable screw terminal connector to con-

nect incoming power. The terminal is located in the top right

corner of the controller when the terminals are facing the user.

See Figure 5.

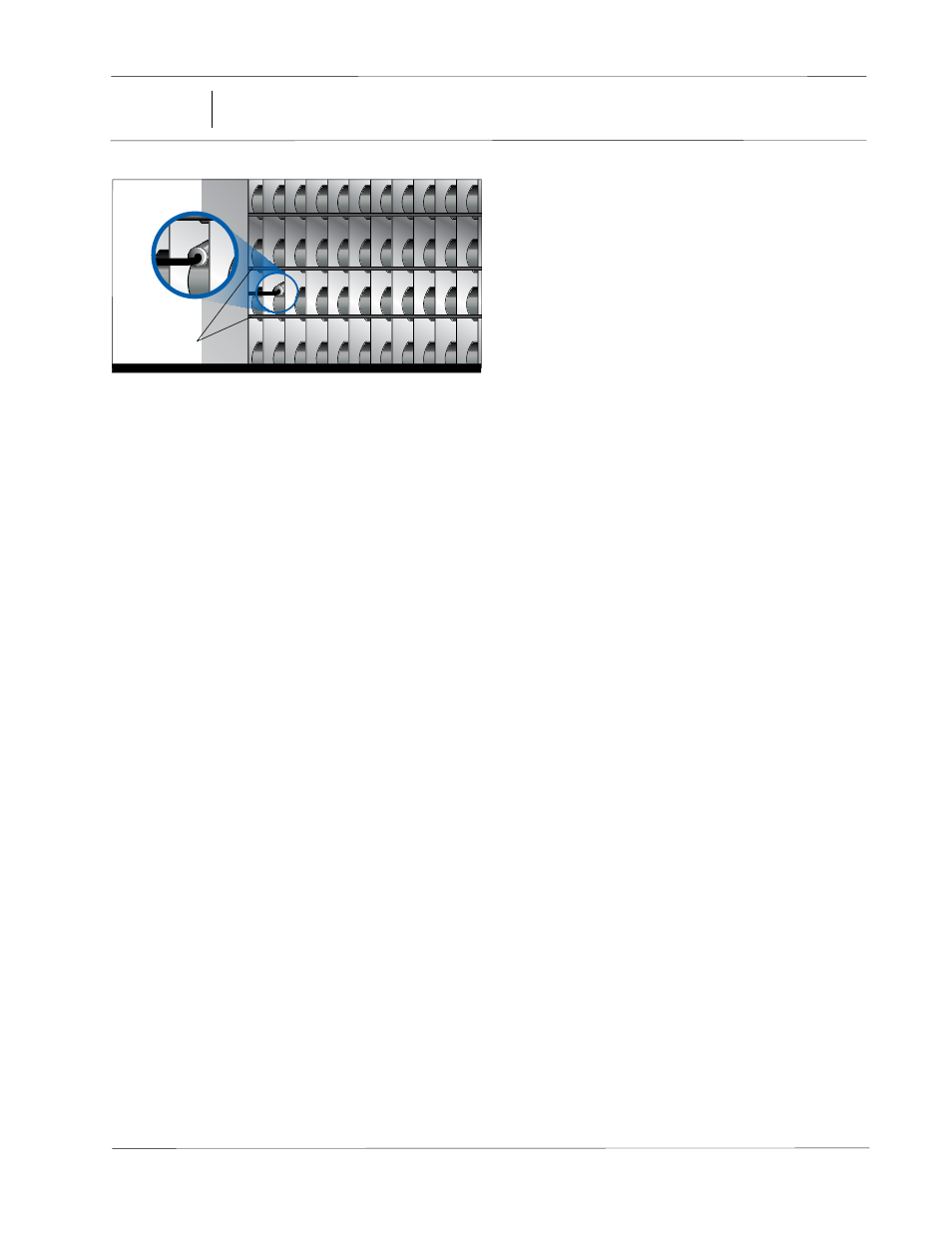

Coil

Sensor

Defrost

Heaters

Figure 4 - Coil Sensor Placement

Fan and Defrost Relays - There are 2 larger relays on the con-

troller with spade connectors. These are used for the evaporator

fans and defrost heaters. Due to the spacing of the enclosure

the spades require a 90 degree terminal. KE2 Therm has includ-

ed (4) spade connectors to assist in wiring the relays.

Evaporator Fan Relay - The fan relay is rated 10A inductive at

240V. One leg of the incoming power for the fans should be

connected to the COM terminal of the fan relay, the upper of the

two larger relays. The remaining leg, (L2) should be connected

to one lead of the fan. The remaining fan lead should be con-

nected to the NO (Normally Open) terminal on the fan relay. See

Figure 7.

Defrost Heater Relay - The heater relay is rated 20A resistive at

240V. One leg of the incoming power for the heaters should be

connected to the COM terminal of the heater relay, the lower

of the two larger relays. The remaining leg, (L2) should be con-

nected to one lead of the heater. The remaining heater lead

should be connected to the NO (Normally Open) terminal on

the heater relay.

Compressor/Liquid Line Solenoid Relay - The compressor re-

lay is rated at 3A induction at 240V. This relay uses the 3-position

pluggable screw terminal to make the connection to the board.

The relay is not intended to control the compressor directly. It is

designed to be used to control the liquid line solenoid or as a pi-

lot to the compressor contactor. One leg of the incoming power

supply (L1) should be connected to COM terminal of the com-

pressor relay, the upper of the two smaller relays. The remaining

leg, (L2), should be connected to one lead on the solenoid/com-

pressor contactor. The remaining lead, should be connected to

the normally open (NO) position on the terminal.

Alarm Relay - The alarm relay is rated at 3A inductive at 240V.

This relay uses the 3-position pluggable screw terminal to make

the connection to the board. The relay may be used to connect

an audible alarm, light, or to alert a 3rd party alarm system. One

leg of the incoming power supply (L1) should be connected to

COM terminal of the alarm relay, the lower of the two smaller

relays. The remaining leg, (L2), should be connected to one lead

on the alarm. The remaining alarm lead, should be connected to

the normally open (NO) position on the terminal.

After all high voltage wiring is completed the metal shield

must be replaced and screws tightened .

Additional Inputs

Suction Temperature Sensor - The suction temperature sen-

sor is required when applying the controller with an electronic

expansion valve. The sensor’s proximity to the evaporator out-

let differs slightly for electronically controlled valves from the

placement of a TEV bulb. Due to the more refined control from

an electronically controlled valve, the sensor must be placed

as close to the outlet of the coil as feasible. Although the dis-

tance from the outlet is different, the nature of the refrigerant’s

flow through the tube remains unchanged, thus the orientation

of the sensor remains at the 4 or 8 o’clock position. The sensor

should be secured to the suction line using the included wire

ties designed for low ambient operation.

Pressure Transducer - In addition to the suction temperature

sensor, a pressure transducer is also required for superheat

measurement when applying an electronic expansion valve.

The pressure tap should be mounted on the top of a horizontal

section of tube. It should be located near the suction sensor, ap-

proximately 3 inches downstream from the position of the tem-

perature sensor.

Auxiliary Temperature Sensor -The auxiliary temperature sen-

sor provides flexibility and may be used for any purpose desired

by the user. The placement of the sensor is dependent on the

requirements of the user’s intended application. The Auxiliary

Temperature sensor must be supplied by KE2 Therm.

Digital Inputs - The controller includes (3) digital inputs. See

Table 3 for configuration options.

5

01/13 Rev. A 151627

Enviro-Control™