Electric defrost - surface heater, Electric defrost - dropped tube, Air defrost – Nor-Lake Enviro-Control IOM User Manual

Page 4: Ke2 evaporator efficiency, Figure 3 - proper sensor location

KE2 EvaporatorEfficiency

Installation Instructions

After the sensor is installed, route the wire back to the control-

ler location. When routing sensor wire, it is important to avoid

interference from high voltage lines. If sensor wire is run parallel

to the high voltage, there is a potential for inductance to affect

the sensor reading. This is of particular concern with long wire

runs. When extending sensors, use the 18 gage, shielded twist-

ed pair. Sensor wires can be run beyond 100 feet when using

special considerations. Contact KE2 Therm. After the wire has

been successfully routed, it may be connected to the pluggable

terminal on the controller.

Coil Temperature Sensor - As a critical input to the control-

ler, it is essential the sensor is located at the coldest point on

the evaporator coil for optimal operation. The coil sensor is an

integral part of the control algorithm used to determine coil ef-

ficiency, to initialize defrosts, and to terminate defrosts.

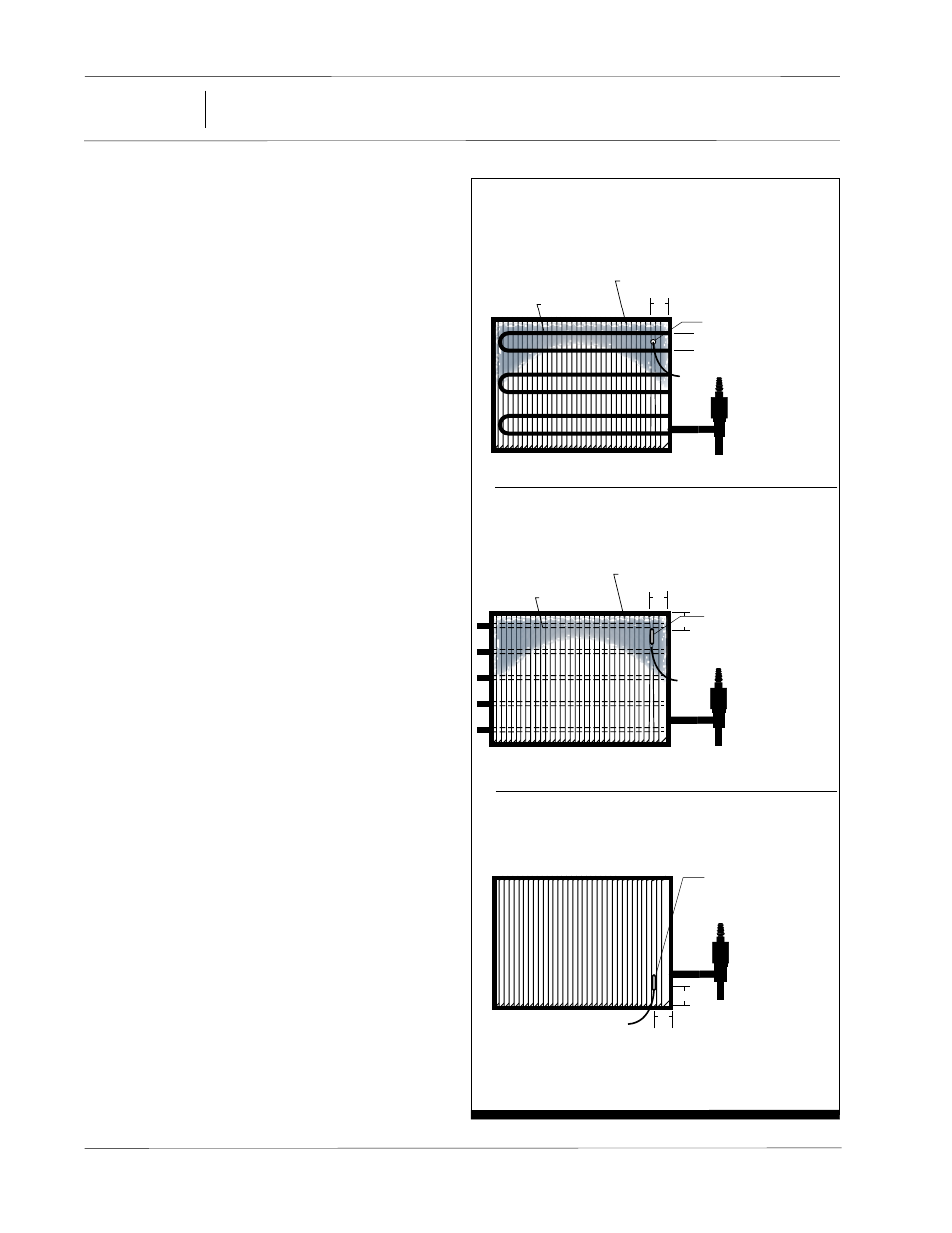

KE2 Therm offers general guidance for sensor locations based

on the coil construction. Figure 3 shows the recommended lo-

cations for the coil sensor for each evaporator type.

When installing on draw through models, the sensor should be

located behind the coil in the lower corner nearest the suction

header. Blow through models should be installed on the front of

the coil, in the upper corner also nearest to the suction header.

When installing the sensor into the coil, the sensor should be po-

sitioned half way between the circuit tubes and, perpendicular

to the face of the coil. When choosing the location, the sensor

should not be located adjacent to the electric heating elements.

Locating the sensor too close to the elements will cause false

defrost termination temperatures. The sensor should be ap-

proximately half the distance between the heaters if possible.

Figure 4 shows the proper sensor placement.

Due to the many factors influencing the evaporator perfor-

mance, it is impossible for KE2 Therm to provide the proper loca-

tion of every installation. However, the coil sensor is an integral

part of the control algorithm used to determine coil efficiency

to initiate, as well as, terminate defrosts. The coldest point in

the coil can be identified from existing system knowledge or by

monitoring the normal operation.

Controller Power - The high voltage wiring is protected by

a metal shield screwed to the back side of the controller. The

shield should be removed to gain access to the wiring connec-

tions, making note of the location of the screws. The screws in

the upper corners are coarse thread screws, while the screw in

the middle is a 4-40 machine screw.

The controller accepts either 115V or 208/240V incoming power.

The controller includes metal oxide varistors (MOVs), providing

protection from voltage spikes. MOVs use the same technology

commonly applied to protect consumer electronics. They func-

tion by filtering out voltages high enough to damage the board.

When the voltage exceeds the allowed amount, the MOVs short

to ground, protecting the circuitry. For additional protection,

the board has a replaceable BK/MDL-1/4 fuse in line. The grey

plug is accessible without removing the metal shield in the fuse

1/2 way

- 1/2 way between heater coils

- insert perpendicular to face of coil

- pinch fins together to hold

Heater Coil

Ideal Sensor Location

Higher Frost Zone

coldest part of

evaporator

Electric Defrost - Surface Heater

- 1/2 way between heater coils

- approx. 3” from top and 3”

from side

- insert parallel to face of coil

- pinch fins together to hold

Heater Coil

Ideal Sensor Location

Higher Frost Zone

coldest part of

evaporator

Electric Defrost - Dropped Tube

- lower corner nearest expansion

valve, approx. 3” from bottom,

and 3” from side

- insert parallel to face of coil

- pinch fins together to hold

Ideal Sensor Location

Air Defrost

3”

3”

3”

3”

3”

Figure 3 - Proper Sensor Location

4

01/13 Rev. A 151627

Enviro-Control™