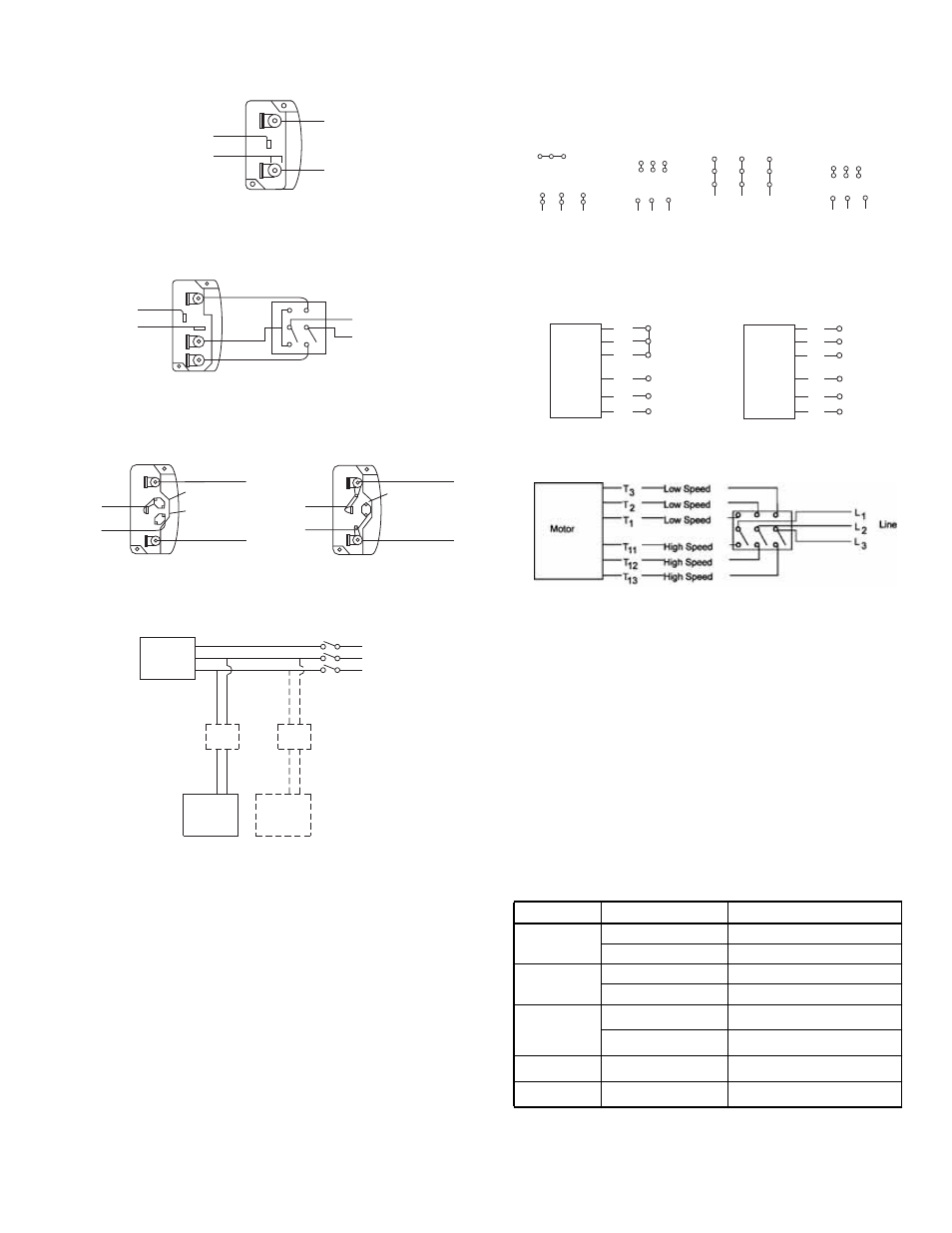

Wiring diagrams, Bearings, Fan bearings – COOK SRSH User Manual

Page 3: Single speed, single phase motor, 3 phase, 9 lead motor

3

4 5 6

1

7

2

8

3

9

L1 L2 L3

4 5 6

7 8 9

1 2

3

L1 L2 L3

Low Voltage

208/230 Volts

High Voltage

460 Volts

3 Phase, 9 Lead Motor

Y-Connection

7

1

6

7 8 9

4 5 6

1 2

3

Low Voltage

208/230 Volts

High Voltage

460 Volts

8

2

4

9

3

5

L1

L3

L2

L1

L3

L2

3 Phase, 9 Lead Motor

Delta-Connection

Wiring Diagrams

Wiring Diagrams

When ground is required, attach to ground A or B with no. 6 thread forming

screw. To reverse, interchange T-1 and T-4.

Single Speed, Single Phase Motor

To reverse, interchange any 2 line leads.

3 Phase, 9 Lead Motor

When ground required, attach to ground A or B with No. 6 thread forming

screw. To reverse, interchange T-1 and T-4 leads.

2 Speed, 2 Winding, Single Phase Motor

2 Speed, 1 Winding, 3 Phase Motor

To reverse, interchange any 2 line leads. Motors require magnetic control.

Single Speed, Single Phase, Dual Voltage

2 Speed, 2 Winding, 3 Phase

When ground required, attach to ground A or B with No. 6 thread forming

screw. To reverse, interchange T-5 and J-10 leads.

To reverse: High Speed-interchange leads T

11

and T

12

.

Low Speed-interchange leads T

1

and T

2

. Both Speeds-interchange any 2

line leads.

Typical Damper Motor Schematic

• Inspect for cleanliness. Clean exterior surfaces only.

Removing dust and grease on motor housing assures

proper motor cooling.

Fan Bearings

The fan bearings are provided prelubricated. Any spe-

cialized lubrication instructions on fan labels supersedes

information provided herein. Bearing grease is a petroleum

lubricant in a lithium base conforming to a NLGI #2 consis-

tency. If user desires to utilize another type of lubricant,

they take responsibility for flushing bearings and lines, and

maintaining a lubricant that is compatible with the installa-

tion.

A NLGI #2 grease is a light viscosity, low-torque, rust-

inhibiting lubricant that is water resistant. Its temperature

range is from -30°F to 200°F and capable of intermittent

highs of 250°F.

Bearings should be relubricated in accordance with the

following condition chart.

Conditions Chart

For moist or otherwise contaminated installations; divide the interval by a

factor of 3. For vertical shaft installations divide the interval by a factor of 2.

RPM

Temp °F

Greasing Interval

Up to 1000

-30 to 120

6 months

120 to 200

2 months

1000 to 3000

-30 to 120

3 months

120 to 200

1 month

Over 3000

-30 to 120

1 month

120 to 200

2 weeks

Any Speed

< -30

Consult Factory

Any Speed

> 200

1 week

For 3 phase, damper motor voltage should be the same between L

1

and

L

2

. For single phase application, disregard L

3

. *Damper motors may be

available in 115, 230 and 460 volt models. The damper motor nameplate

voltage should be verified prior to connection. ** A transformer may be

provided in some installations to correct the damper motor voltage to the

specified voltage.

Fan

Motor

Damper

Motor*

Second

Damper

Motor

Transformer**

Transformer**

L3

L2

L1

Ground A

Ground B

T-1

T-4

Low Speed

High Speed

L 1

L 2

Line

Ground B

J-10

T-5

Ground A

Link A

Link B

Low Voltage

Line

L 2

L 1

Ground A

Link A & B

L1

L 2

Line

Ground B

T-5

J-10

Motor

1

2

3

4

5

6

Together

High Speed

Line

L1

L2

L3

1

2

3

4

5

6

Open

Low Speed

Line

L1

L2

L3

Motor

T-1

T-4

Ground B

L2

L1

Ground A

Line