Inspection, Filter, Maintenance – COOK ETS User Manual

Page 4: Lubricants, Motor bearings, Fan bearings, Motor services, Changing shaft speed

4

Start Up

Turn the fan on. In variable speed units, set the fan to its

lowest speed. Inspect for the following:

• Direction of rotation.

• Excessive vibration.

• Unusual noise.

• Bearing noise.

• Improper belt alignment or tension (listen for a continu-

ous squealing noise).

• Improper motor amperage or voltage.

If a problem is discovered, immediately shut off the

fan. Lock out all electrical power and check for the

cause of the trouble. Refer to Troubleshooting, page 5.

Inspection

Inspection of the fan should be conducted at the first 30

minute, 8 hour and 24 hour intervals of satisfactory opera-

tion. During the inspections, stop the fan and inspect as per

the chart below.

30 Minute Interval

Inspect bolts, setscrews, and motor mounting bolts.

Adjust and tighten as necessary.

8 Hour Interval

Inspect belt alignment and tension. Adjust and tighten as

necessary.

24 Hour Interval

Inspect belt tension. Adjust and tighten as necessary.

Filter

If you fan is not supplied with filters proceed to Mainte-

nance.

Inspect filters within the first two weeks of operation. If

there is no excessive build-up, monthly servicing should be

adequate.

To clean reusable aluminum filters, back flush with soap

and water. When clean, shake off excess water and allow

the filter to air-dry before reinstalling it.

Maintenance

Establish a schedule for inspecting all parts of the fan.

The frequency of inspection depends on the operating con-

ditions and location of the fan.

Inspect fans exhausting corrosive or contaminated air

within the first month of operation. Fans exhausting contam-

inated air (airborne abrasives) should be inspected every

three months. Clean the propeller and air inlets if material

build-up is excessive. Excessive build-up can cause imbal-

ance and failure of the propeller.

Regular inspections are recommended for fans exhaust-

ing non-contaminated air.

It is recommended the following inspections be con-

ducted twice per year.

• Inspect bolts and setscrews for tightness. Tighten as

necessary.

• Inspect belt wear and alignment. Replace worn belts

with new belts and adjust alignment as needed. See

WARNING

Disconnect power before checking and cleaning

filters. Inadvertent operation of the fan could pull

objects from the roof into the propeller.

Belt and Pulley Installation, page 2.

• Bearings should be inspected as recommended in the

Conditions Chart.

• Inspect for cleanliness. Clean exterior surfaces only.

Removing dust and grease on motor housing assures

proper motor cooling.

Lubricants

Loren Cook Company uses petroleum lubricant in a lith-

ium base conforming to NLGI grade 2 consistency. Other

grades of grease should not be used unless the bearings

and lines have been flushed clean. If another grade of

grease is used, it should be lithium-based.

A NLGI grade 2 grease is a light viscosity, low-torque,

rust-inhibiting lubricant that is water resistant. Its tempera-

ture range is from -30

°F to +200°F and capable of intermit-

tent highs of +250

°F.

Motor Bearings

Motor bearings are pre-lubricated and sealed. Under nor-

mal conditions they will not require further maintenance for

a period of ten years. However, it is advisable to have your

maintenance department remove and disassemble the

motor, and lubricate the bearings after three years of oper-

ation in excessive heat and or in a contaminated airstream

consisting of airborne abrasives.

Fan Bearings

Fan bearings are lubricated through a grease connector

and should be lubricated by the schedule, Conditions

Chart, shown above.

For best results, lubricate the bearing while the fan is

rotating. Slowly pump grease into the bearing until a slight

bead forms around the bearing seals. Excessive grease

can burst seals thus reduce bearing life.

In the event the bearing cannot be seen, use no more

than three injections with a hand-operated grease gun.

Motor Services

Should the motor prove defective within a one-year

period, contact your local Loren Cook representative or

your nearest authorized electric motor service representa-

tive.

Changing Shaft Speed

All belt driven propeller roof fans with motors up to and

including 5HP are equipped with variable pitch pulleys. To

change the fan speed, perform the following:

a. Loosen setscrew on driver (motor) pulley and remove

key, if equipped.

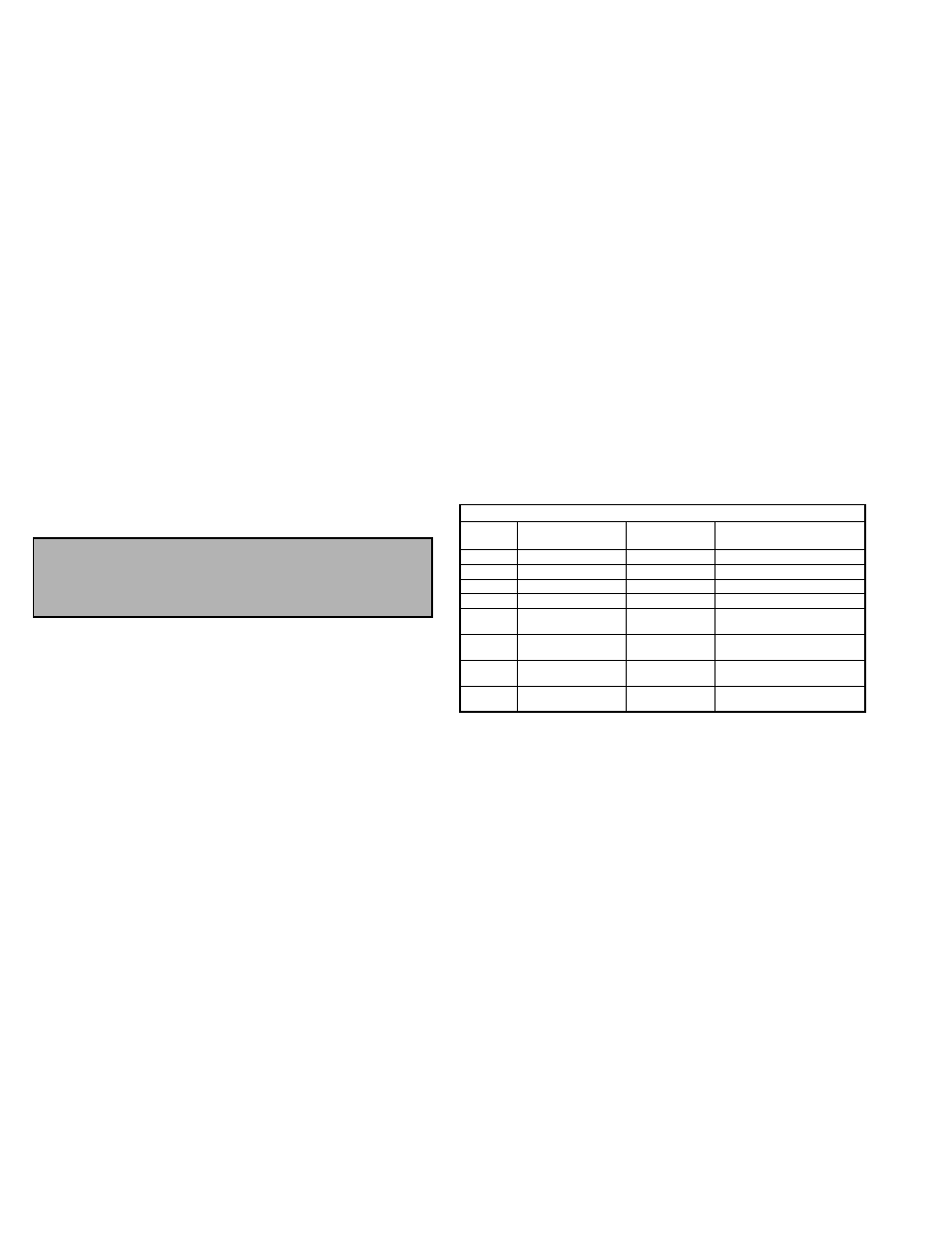

Conditions Chart

RPM

Temperature

Fan

Status

Greasing

Interval

100

Up to 120°F

Clean

6 to 12 months

500

Up to 150°F

Clean

2 to 6 months

1000

Up to 210°F

Clean

2 weeks to 2 months

1500 Over

210°F

Clean

Weekly

Any

Speed

Up to 150°F

Dirty

1 week to 1 month

Any

Speed

Over 150°F

Dirty

Daily to 2 weeks

Any

Speed

Any Temperature

Very Dirty

Daily to 2 weeks

Any

Speed

Any Temperature

Extreme

Conditions

Daily to 2 weeks