COOK Laboratory Exhaust User Manual

Page 15

6.4

Piping & Control

Consult the job specification for the specific piping requirements for each unit.

6.5

Condensate Drain

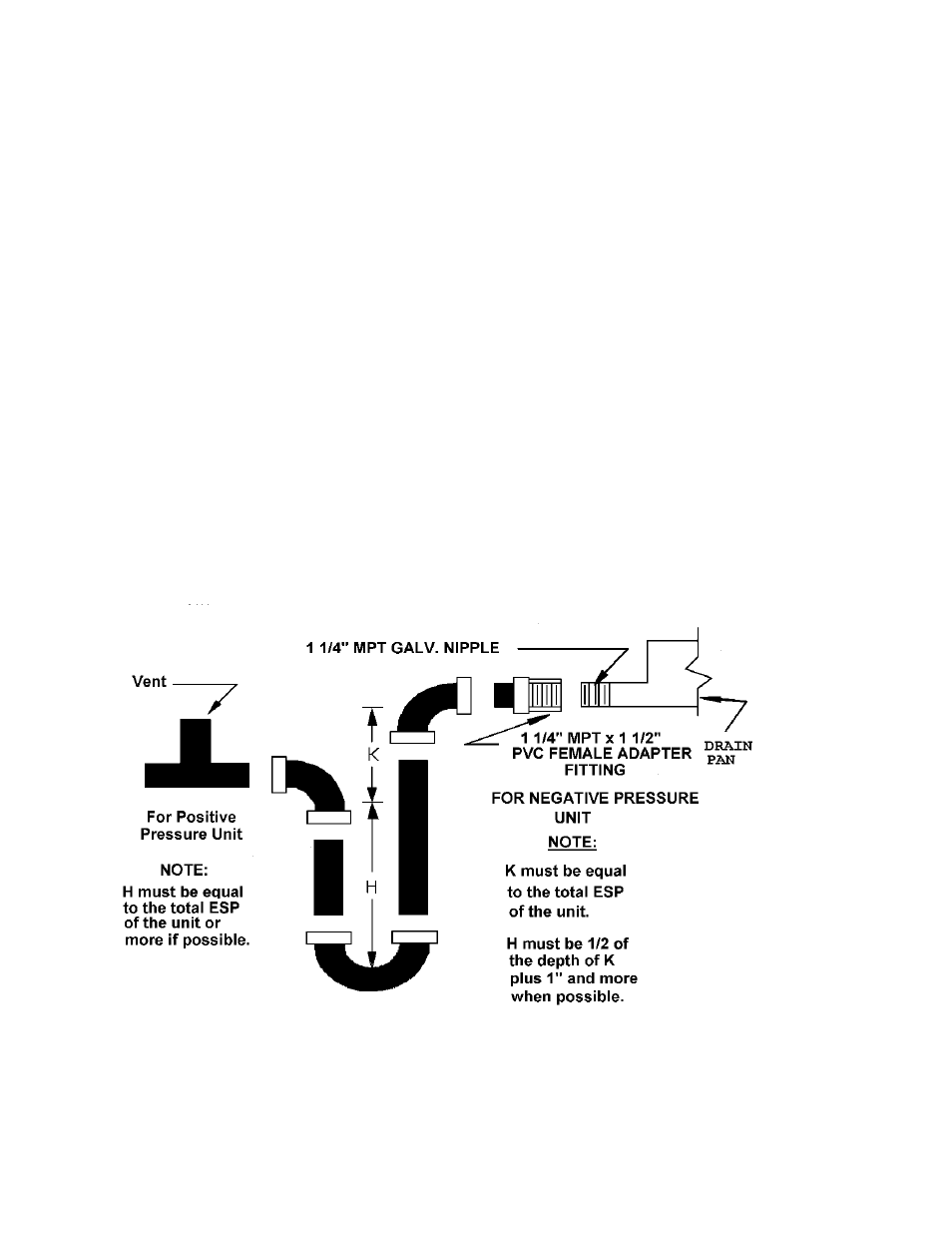

The majority of evaporator coils are located in the units so that the supply air is drawn through them. This results

in the condensate being induced to the area of low static pressure. Unless some means of pressure

equalization is provided in the condensate drain, the air rushing through the drain will cause the condensate to

accumulate in the drain pan. As the unit continues to operate, the accumulated water will be picked up by the in-

rushing air and carried with the air over the side of the drain pan causing possible water leaks into the supply

duct and/or through the bottom of the unit causing water damage in the building. A minimum trap should be

installed to prevent this condensate water buildup. See illustration below. On initial start-up, it may be necessary

to fill the trap manually or, after the unit has operated sufficiently for a small amount of condensate to collect in

the drain pan, turn off the unit and the trap will automatically fill.

Winter Operation

Special care is to be taken to prevent freezing during winter operation when conditions are at or below freezing.

See local codes for procedures and applications used unique to the region the equipment is installed to prevent

freezing and possible damage.

Note: If lengthy drain lines are used to drain the condensation into roof drains, it may be necessary to

use anti-slime tablets in drain pan to prevent clogging.