Wheel, Belt, Wheel-to-inlet clearance – COOK UCIC User Manual

Page 3: Belt and pulley installation

3

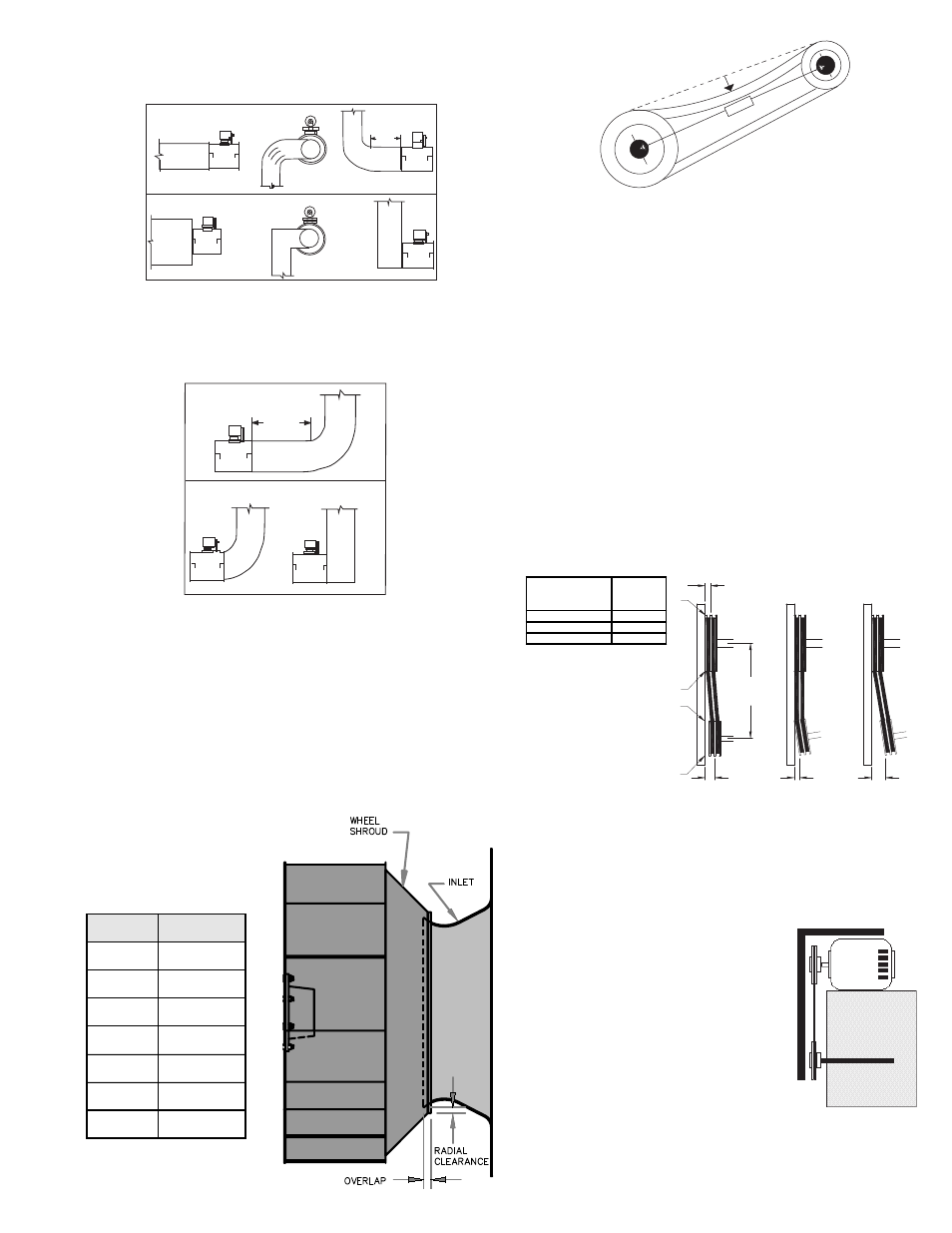

Inlet Duct Turns

For ducted inlets, allow at least 3 fan wheel diameters

between duct turns or elbows and the fan inlet.

Discharge Duct Turns

Where possible, allow 3 duct diameters between duct

turns or elbows and the fan outlet. Refer to the drawing

below.

Wheel-to-Inlet Clearance

The correct wheel-to-inlet clearance is critical to proper

fan performance. This clearance should be verified before

initial start-up since rough handling during shipment could

cause a shift in fan components. Refer to wheel/inlet draw-

ing below for correct overlap.

Adjust the overlap by loosening the wheel hub and mov-

ing the wheel along the shaft to obtain the correct value.

A uniform radial gap (space between the edge of the

cone and the edge of the

inlet) is obtained by loosen-

ing the inlet cone bolts and

repositioning the inlet cone.

Size

Overlap

60 - 165

3/16”

180 - 245

1/4”

270- 300

5/16”

330 - 365

3/8”

402

7/16”

445 - 490

1/2”

540 - 730

13/16”

Inlet Duct Turns

Correct

Incorrect

MIN

3 DIA

Discharge Duct Turns

Correct

Incorrect

MIN

3 DIA

Belt and Pulley Installation

Belt tension is determined by the sound the belts make

when the fan is first started. Belts will produce a loud

squeal which dissipates after the fan is operating at full

capacity. If the belt tension is too tight or too loose, lost effi-

ciency and possible damage can occur.

Do not change the pulley pitch diameter to change ten-

sion. This will result in a different fan speed than desired.

a. Loosen motor plate adjustment nuts and move motor

plate in order that the belts can easily slip into the

grooves on the pulleys. Never pry, roll, or force the

belts over the rim of the pulley.

b. Adjust the motor plate until proper tension is reached.

For proper tension, a deflection of approximately 1/4”

per foot of center distance should be obtained by

firmly pressing the belt. Refer to Figure 3.

c. Lock the motor plate adjustment nuts in place.

d. Ensure pulleys are properly aligned. Refer to Figure 4.

Pulley Alignment

Pulley alignment is adjusted by loosening the motor pulley

setscrew and by moving the motor pulley on the motor shaft.

Figure 4 indicates where to measure the allowable gap

for the drive alignment tolerance. All contact points (indi-

cated by WXYZ) are to have a gap less than the tolerance

shown in the table. When the pulleys

are not the same width, the allowable

gap must be adjusted by half of the dif-

ference in width (As shown in A & B of

Figure 4). Figure 5 illustrates using a

carpenter’s square to adjust the posi-

tion of the motor pulley until the belt is

parallel to the longer leg of the square.

1 foot

1/4 inch

Figure 3

Figure 4

Tolerance

Center Distance

Maximum

Gap

Up thru 12”

1/16”

12” up through 48

1/8”

Over 48”

1/4”

OFFSET

ANGULAR

OFFSET/ANGULAR

A

W

X

Y

Z

B

CENTER

DISTANCE

(CD)

GAP

GAP

Figure 5