Troubleshooting, Motor services, Changing shaft speed – COOK KSP User Manual

Page 6: Replacing pulleys and belts, Bearing replacement

6

individually for each side of fan.

An emery cloth or file may be needed to remove imper-

fections in the shaft left by the setscrews.

a. Remove topcap.

b. Loosen motor plate adjustment bolts, then move the

motor plate so the belt will easily slip off. Remove

driven pulley by loosening the setscrews.

c. Remove the bearings from shaft.

d. Slide new bearings onto shaft to desired location and

mount bearings loosely onto support base. Bearing

bolts and setscrews should be loose to allow shaft

positioning.

e. Position the wheel properly and tighten the bearing

bolts securely to the support base.

f. Align setscrews bearing to bearing and tighten against

the shaft securely.

Never tighten both pairs of setscrews before

securing bearing mounting bolts. This may dam-

age the shaft.

g. Check wheel position again. If necessary, readjust by

loosening the bearing bolts and setscrew and repeat

step e.

Troubleshooting

Problem and Potential Cause

Low Capacity or Pressure

•Incorrect direction of rotation. Make sure the fan rotates in same di-

rection as the arrows on the motor or belt drive assembly.

•Poor fan inlet conditions. There should be a straight clear duct at the

inlet.

•Improper wheel alignment.

Excessive Vibration and Noise

•Damaged or unbalanced wheel.

•Belts too loose; worn or oily belts.

•Speed too high.

•Incorrect direction of rotation. Make sure the fan rotates in same di-

rection as the arrows on the motor or belt drive assembly.

•Bearings need lubrication or replacement.

•Fan surge.

Overheated Motor

•Motor improperly wired.

•Incorrect direction of rotation. Make sure the fan rotates in same di-

rection as the arrows on the motor or belt drive assembly.

•Cooling air diverted or blocked.

•Improper inlet clearance.

•Incorrect fan RPMs.

•Incorrect voltage.

Overheated Bearings

•Improper bearing lubrication

•Excessive belt tension.

Motors are provided with a polyurea mineral oil NGLI #2

grease. All additions to the motor bearings are to be with a

compatable grease such as Exxon Mobil Polyrex EM and

Chevron SRI.

The above intervals should be reduced to half for vertical

shaft installations.

Motor Services

Should the motor prove defective within a one-year

period, contact your local Loren Cook representative or

your nearest authorized electric motor service representa-

tive.

Changing Shaft Speed

All belt driven fans with motors up to and including 5 HP

are equipped with variable pitch pulleys. To change the fan

speed, perform the following:

a. Loosen setscrew on driver (motor) pulley and remove

key, if equipped.

b. Turn the pulley rim to open or close the groove facing.

If the pulley has multiple grooves, all must be adjusted

to the same width.

c. After adjustment, inspect for proper belt tension.

Speed Reduction

Open the pulley in order that the belt rides deeper in

the groove (smaller pitch diameter).

Speed Increase

Close the pulley in order that the belt rides higher in

the groove (larger pitch diameter). Ensure that the RPM

limits of the fan and the horsepower limits of the motor

are maintained.

Replacing Pulleys and Belts

a. Remove pulleys from their respective shafts.

b. Clean the motor and fan shafts.

c. Clean bores of pulleys and coat the bores with heavy

oil.

d. Remove grease, rust, or burrs from the pulleys and

shafts.

e. Remove burrs from shaft by sanding.

f. Place fan pulley on fan shaft and motor pulley on its

shaft. Damage to the pulleys can occur when exces-

sive force is used in placing the pulleys on their

respective shafts.

g. Tighten in place.

h. Install belts on pulleys and align as described in the

Belt and Pulley Installation section.

Bearing Replacement

The fan bearings for the 200 ASP, ASP-T and KSP are

pillow block ball bearings. Bearings should be replaced

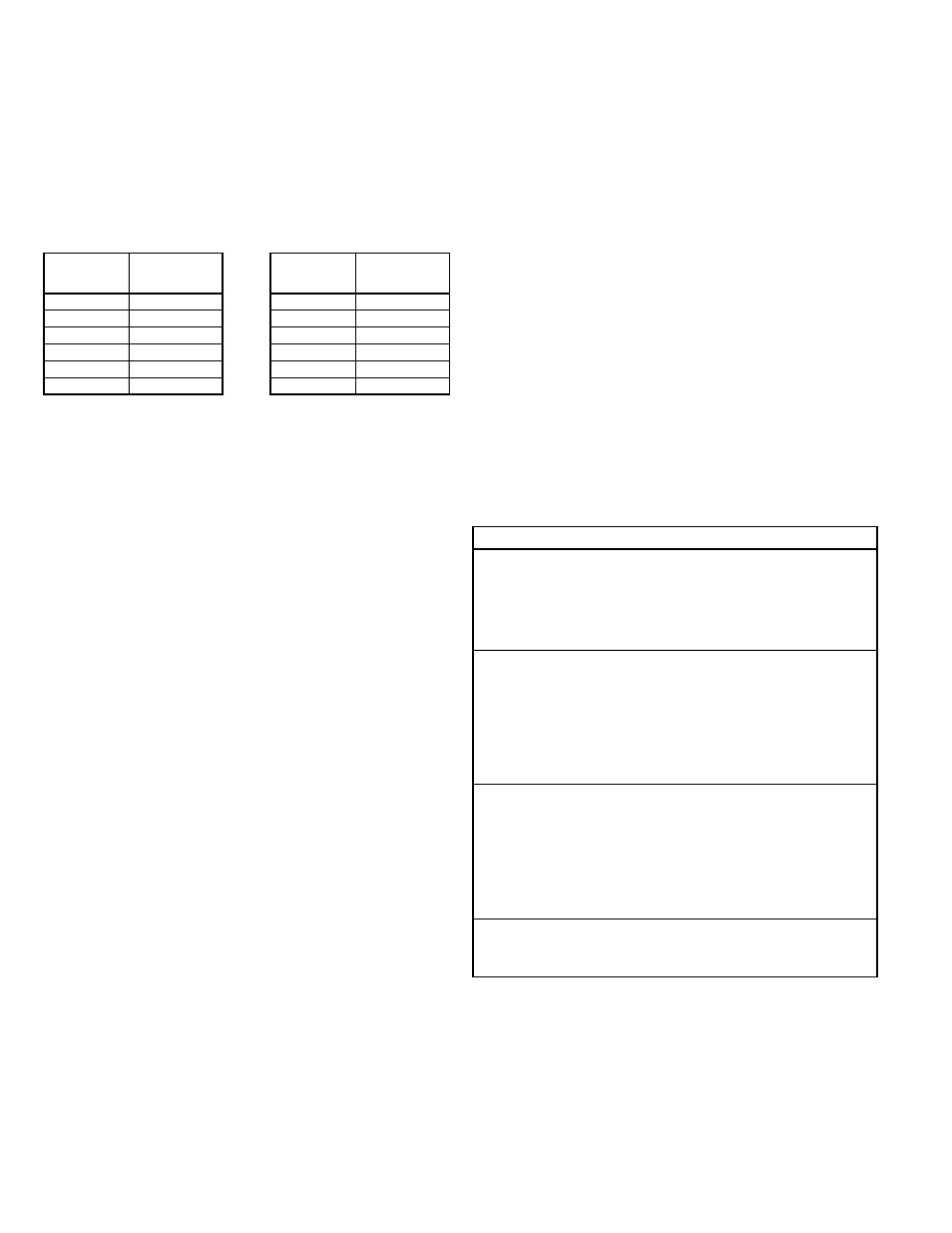

Maximum RPM

ASP/ASP-T

Size

Maximum

RPM

KSP

Size

Maximum

RPM

90

1665

90

1672

100

1519

100

1534

120

1223

120

1297

150

1075

150

1052

180

978

180

979

200

844

200

835