Attention! become alert! your safety is involved, Maintenance – Alamo RHINO 7214 MSL User Manual

Page 38

TILT CYLINDER REASSEMBLY CONTINUED

6. Place o-ring (5) and backup ring (4) in groove in

outside of head (8). Make sure o-ring and backup ring

are installed as shown in cutout illustration for head

(8).

7. Remove sharp edges on outer edge of threaded end of

shaft (19). Lubricate wiper seal (18) and rod seal (7) in

head (17) and carefully slide head onto shaft in

orientation shown.

8. Place o-ring (14) into groove inside piston, and seal

components (11-13) into groove on outside of piston.

Lubricate o-ring (14) and slide piston onto threaded

shaft (19) in orientation shown.

9. Clean internal and external threads on shafts (19 & 3)

with parts cleaner, dry and apply Loctite

®

271 to

threads on shaft (19), then assemble shaft (3) to cross

head shaft (19). Tighten to 450-500 ft.·lbs. torque.

10.Lubricate o-ring (5), backup ring (4), wiper seal (6),

and rod seal (7). Carefully slide cylinder head (8) into

cylinder tube (1), then into inner tube. Turn tube (1)

with open end facing up and use a shaft or tube to seat

head into tube. Be careful not to score cylinder wall.

Install plug (20), apply Loctite and install set screws

(21) in place. Seat set screws equally from each side.

11.Apply a light coating of oil to shaft and piston seals.

Turn tube (1) horizontal and secure in vise. Turn shaft,

piston, and head assembly so hole in shaft (3) is

horizontal and slide into cylinder, guiding rod into head

(8).

12.Lubricate o-ring (15) and backup ring (16), then

carefully slide piston and head into cylinder tube (1).

13.Insert wire retaining ring (2) into slot in cylinder tube

(1). Apply pressure to wire ring to thread it into groove

while turning cylinder head.

© 2004 Alamo Group Inc.

MAINTENANCE

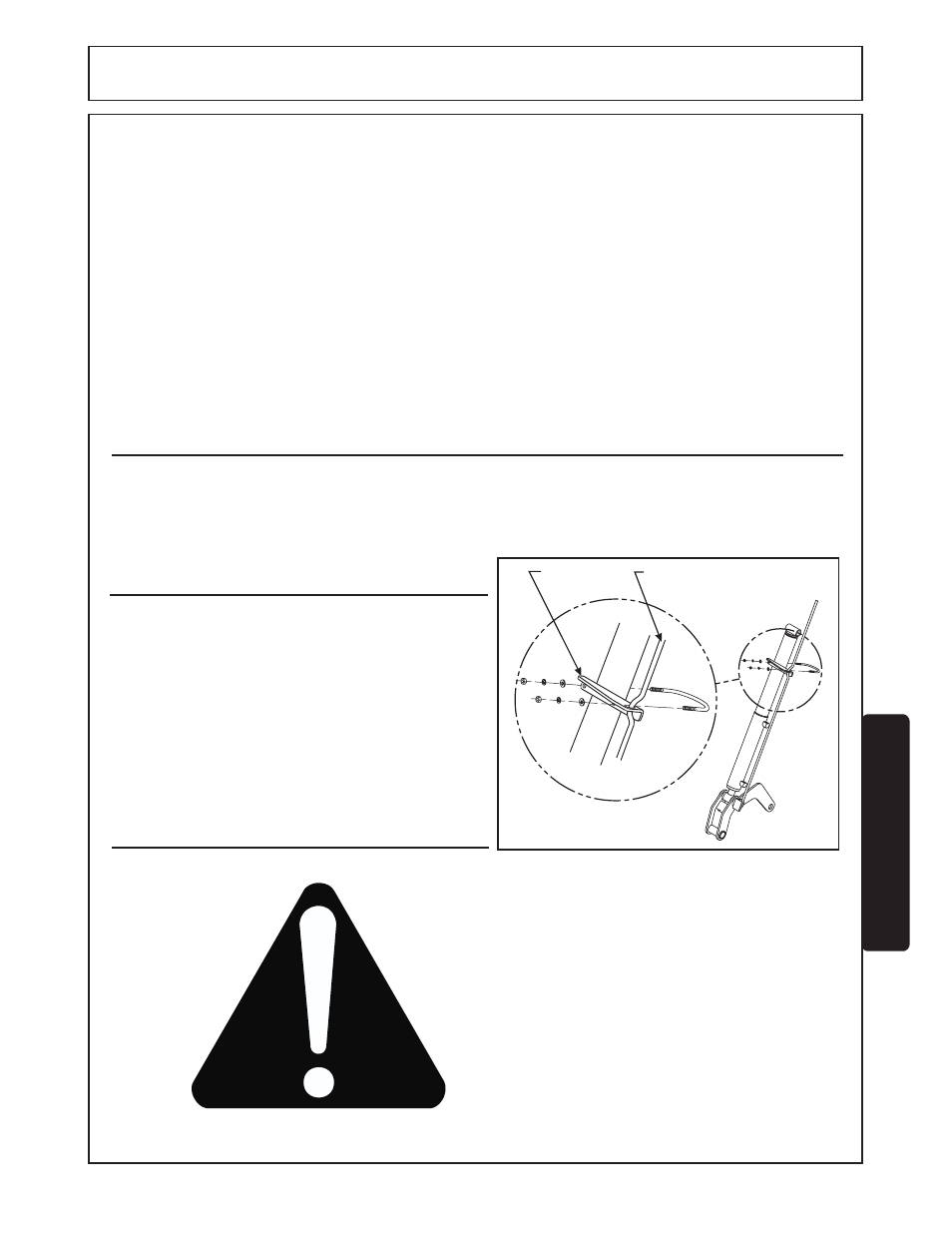

ADJUSTING ATTACHMENT LEVEL INDICATOR

With various tractor tire options or attachments, it may be

necessary to adjust attachment level indicator bracket up

or down tilt cylinder tube. Tractor must be on level surface

with attachment flat on surface. Loosen u-bolt to adjust.

Offset on bucket level indicator rod should be at slotted

hole when attachment is level.

MAINTENANCE

REPLACING WEAR BUSHINGS

Loader lift and tilt cylinders are manufactured with

replaceable wear bushings at each end. (Refer to

cylinder illustrations on previous pages.) Wear bushings

are designed to be easily replaced using tools ordinarily

available.

1. Use a drift pin to remove wear bushing.

2. Press replacement bushing in place using mallet and

block of wood, or similar method.

F-3778-12-04

Maintenance Section 5-5

Level indicator

bracket

Level Indicator

Rod

THIS SAFETY SYMBOL MEANS

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS

INVOLVED!