Tilt cylinder service -4, Maintenance – Alamo RHINO 7214 MSL User Manual

Page 37

© 2004 Alamo Group Inc.

MAINTENANCE

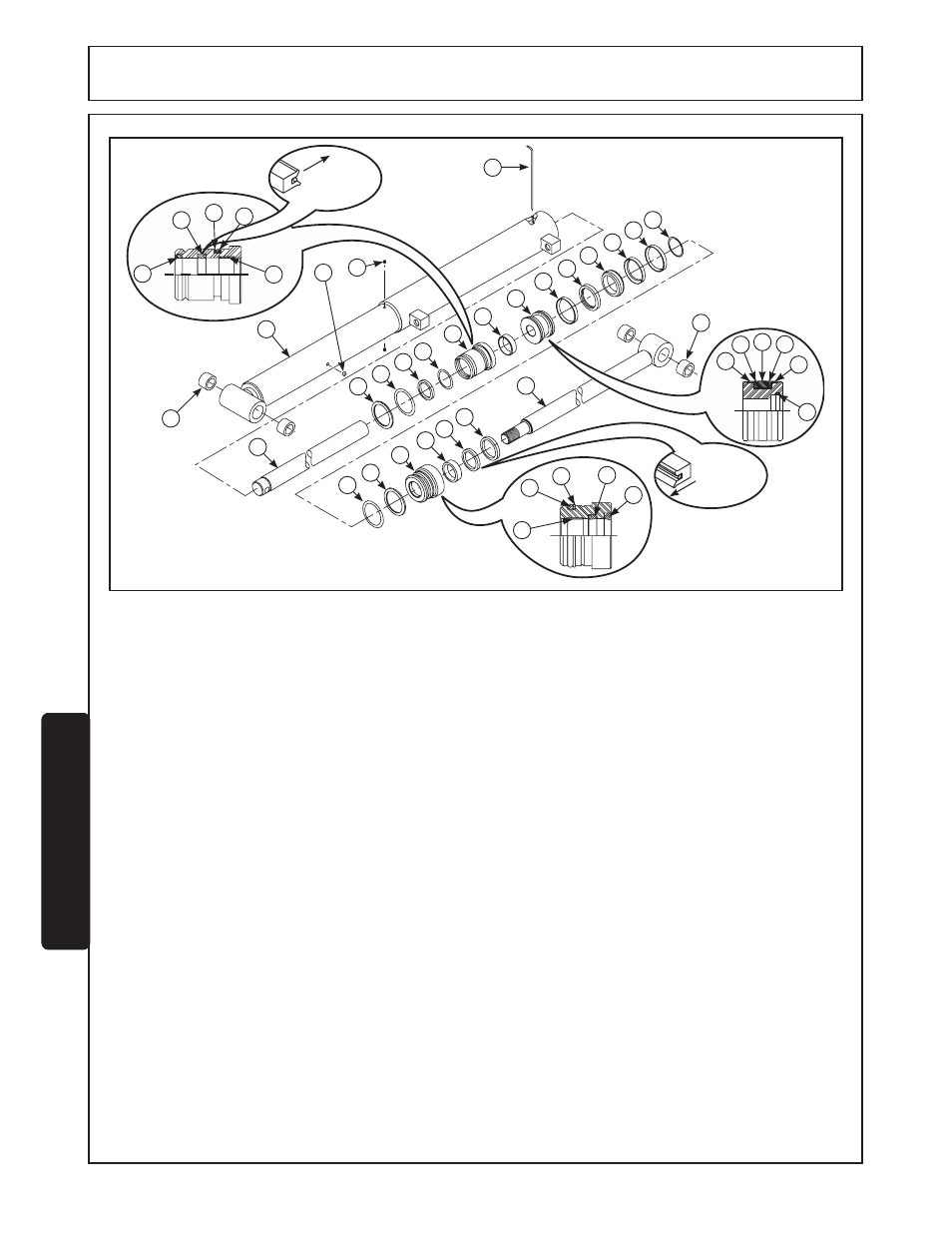

TILT CYLINDER DISASSEMBLY

1. Remove cylinder from loader.

2. Secure cylinder in a vise and manually extend and

retract cylinder rod to remove oil in cylinder.

3. With cylinder rod fully extended, remove set screws

(21) from cylinder. Remove plug (20) and apply air

pressure into hole where plug was removed. This will

unseat internal head (8) and move it along cylinder

rod.

4. Hold cylinder tube (1) stationary and pull retaining wire

(2) out through slot while turning head (17) in same

direction.

5. Pull shaft (19) with all assembled parts out of cylinder

tube (1).

6. Remove internal head (8) from cylinder shaft.

7. To remove piston from rod assembly, hold shaft

assembly by placing a rod through hole in shaft (3) and

a shaft through cross head shaft (19) and turn

counterclockwise.

8. Remove wiper seal (6), rod seal (7), and wear ring (9)

from inside cylinder head (8), and backup ring (4) and

o-ring (5) from groove on outside of head (17).

9. Remove wiper seal (18), rod seal (7), and wear ring (9)

from inside cylinder head (17), and o-ring (15) with

backup ring (16) from groove on outside of head (17).

10.Remove piston wear rings (11), support rings (12), and

seal (13) from outside groove of piston (10).

11.Clean all parts, including cylinder tube, in suitable

cleaning solvent, then use air pressure to blow away

any dirt or excess solvent from all parts.

12.Examine all parts for wear or damage and replace, if

necessary.

TILT CYLINDER REASSEMBLY

NOTE: Be careful not to damage seals and o-rings on

edges or holes in cylinder tube. Inspect and remove burrs

and sharp edges if necessary before reassembly.

1. Place rod seal (7) into groove inside cylinder heads (8

& 17).

NOTE: Lips of seal (7) must face pressure side of

cylinder as shown in cutout illustrations of head

assemblies and seal must be firmly seated in grooves.

2. Install wiper seal (6) with lip of seal facing out into

groove on cylinder head (8).

3. Install wiper seal (18) with lip facing out and flush with

top of cylinder head (17).

4. Install wear ring (9) inside other end of cylinder heads

(8 & 17).

5. Place backup ring (16) and o-ring (15) in groove on

outside of head (17). Make sure o-ring and backup ring

are installed as shown in cutout illustration for head

(17).

MAINTENANCE

1

20

22

23

21

2

3

15

16

17

9

7

18

9

15

16

7

18

19

4

5

6

7

8

9

10

11

12

13

12

11

14

6

7

4

5

9

11

12

13

12

11

14

Lips of seal

(7) must face

inward.

Lips of seal

(7) must face

inward.

F-3778-12-04

Maintenance Section 5-4

TILT CYLINDER