Daily maintenance -2, Maintenance – Alamo RHINO 7214 MSL User Manual

Page 35

F-3778-12-04

Maintenance Section 5-2

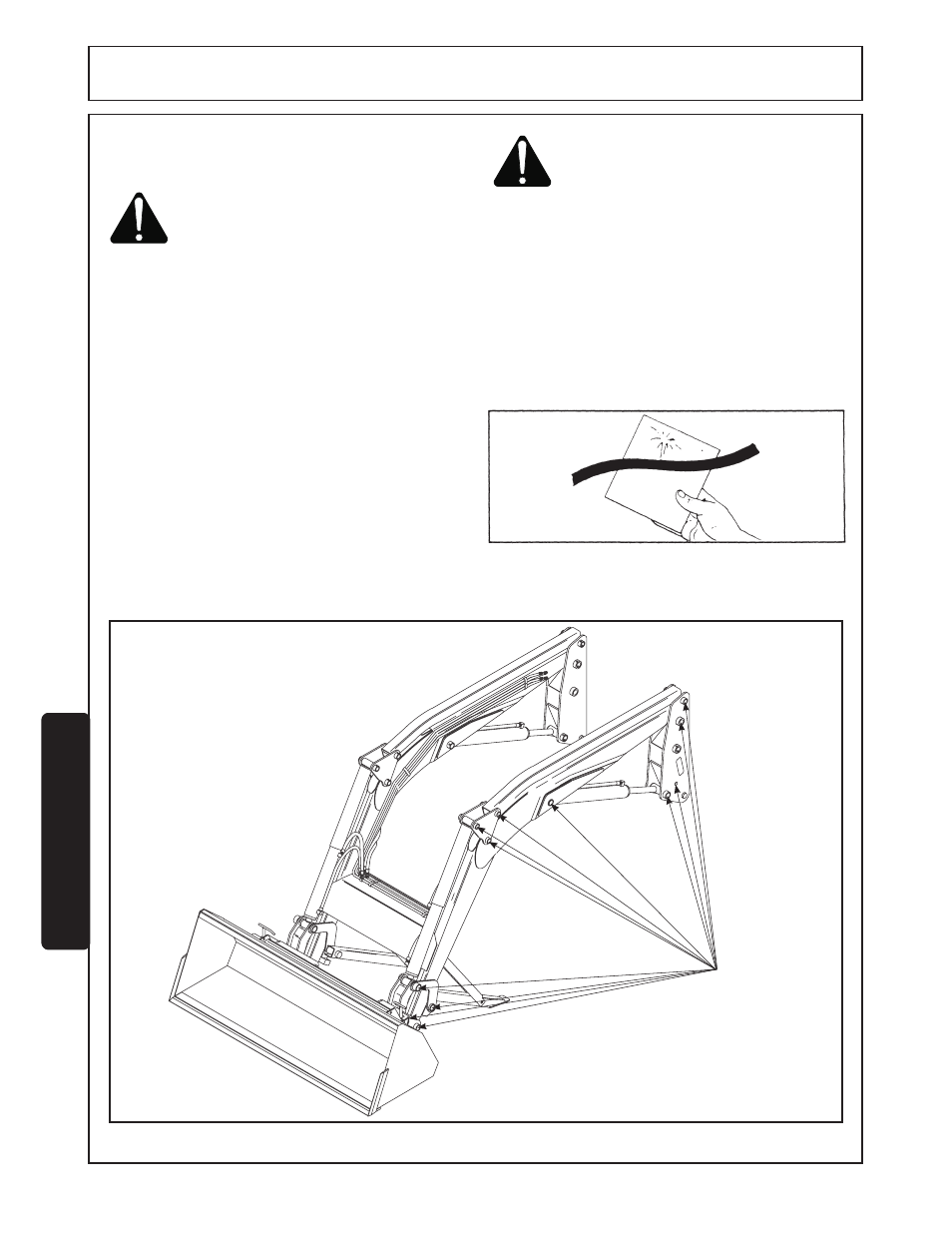

GREASE

POINTS

© 2004 Alamo Group Inc.

MAINTENANCE

MAINTENANCE

Regular maintenance of your loader and hydraulic system

will ensure maximum loader efficiency and long life.

WARNING: NEVER perform maintenance

beneath a raised loader unless loader is

properly supported to prevent accidental

lowering.

DAILY MAINTENANCE

•

Check fluid level of tractor hydraulic system

before starting each day's operation. If

necessary, add hydraulic oil as recommended

in your tractor operator's manual.

•

Every four hours of operation, lubricate all

twenty-two grease fittings. One grease fitting on

the end of each pin, accessible from outside the

loader.

•

Repair hydraulic oil leaks promptly to avoid loss

of oil and serious personal injury from escaping

oil.

•

Replace hoses immediately if they are damaged

by a cut or scrape, extruded at the fittings, or

leaking.

•

After every ten hours of operation, check all

hardware and tighten where required.

WARNING: Escaping hydraulic fluid under

pressure can penetrate skin, causing serious

personal injury.

•

DO NOT use your hand to check for leaks. Use

a piece of wood or cardboard and wear eye

protection to search for leaks.

•

Stop engine and relieve pressure before

connecting or disconnecting lines.

•

Tighten all connections before starting engine or

pressurizing lines.

If any fluid is injected into skin, obtain medical attention

immediately or gangrene may result.

Grease Fitting Locations