Operation – Alamo RHINO 7214 MSL User Manual

Page 24

© 2004 Alamo Group Inc.

OPERATION

PREPARING TRACTOR PRIOR TO OPERATION

WARNING: Read all operator's manuals

before inspecting, servicing or operating

loader and tractor.

INSPECTION

Thoroughly inspect your fully assembled tractor and

loader prior to operation.

1. Check all hardware to be sure that it has been properly

installed and tightened. Retighten all hardware after 10

hours of initial operation.

2. Check tire pressure. Refer to tractor operator's manual

for recommended pressures.

3. With tractor on level surface, compare tractor rear axle

height from left to right, measuring from axle center to

ground. Adjust air pressure in rear tires until axle

height measures same for both sides.

NOTE: If rear axle on tractor is not level from side to

side, cutting edge on loader bucket will not sit flat on

ground.

4. Review tractor lubrication schedule and consult

MAINTENANCE section of this manual to be certain all

pivot points have been properly lubricated.

5. Use instructions listed in MAINTENANCE section of

this manual to check all hose and tubing connections

to insure no leaks are present.

INSTALL COUNTERBALANCE

WARNING: Before operating tractor and

loader, add sufficient counterweight so a

minimum of 25% of total weight of tractor,

loader and rated load is on rear wheels when

bucket contains rated load and is in maximum

forward position.

Sufficient weight can be added to tractor by filling rear

wheels with liquid ballast, installing wheel weights or 3-

point hitch counterweight. If 3-point hitch counterweights

are used, they should be carried as low as possible at all

times to maximize stability.

Effective counterbalance weight of mounted rear

equipment is determined by multiplying actual weight of

equipment by 1.50.

EXAMPLE: Equipment weighing 800 pounds, attached

to rear of tractor, multiplied by 1.50, equals 1200 pounds

of effective counterbalance weight.

After adding recommended counterweight, weigh tractor

at rear axle to be sure counterbalance is adequate.

FILLING THE BUCKET

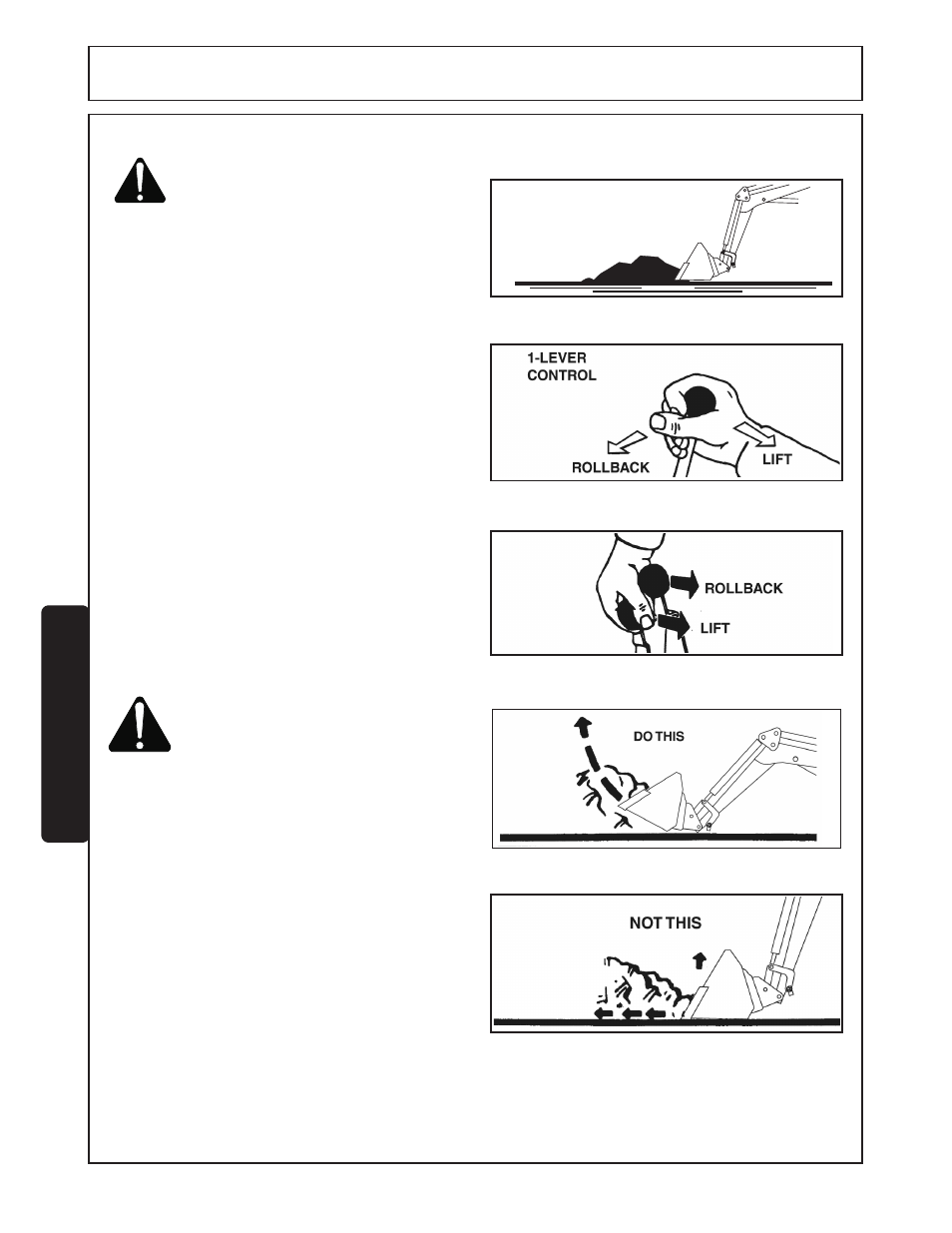

Approach and enter the pile with a level bucket.

Loaders with 1-lever control, ease lever back and away

from you to lift and roll back bucket.

Loaders with 2-lever controls, ease both levers back to lift

and roll back bucket.

Lift and roll back of bucket will increase efficiency

because...

... A level bucket throughout the lifting cycle resists bucket

lift and increases breakaway effort.

NOTE: Do not be concerned if the bucket is not

completely filled during each pass. Maximum productivity

is determined by the amount of material loaded in a given

period of time. Time is lost if two or more attempts are

made to fill the bucket on each pass.

OPERATION

F-3778-12-04

Operation Section 4-2