Lift cylinder service -3, Maintenance – Alamo RHINO 7214 MSL User Manual

Page 36

F-3778-12-04

Maintenance Section 5-3

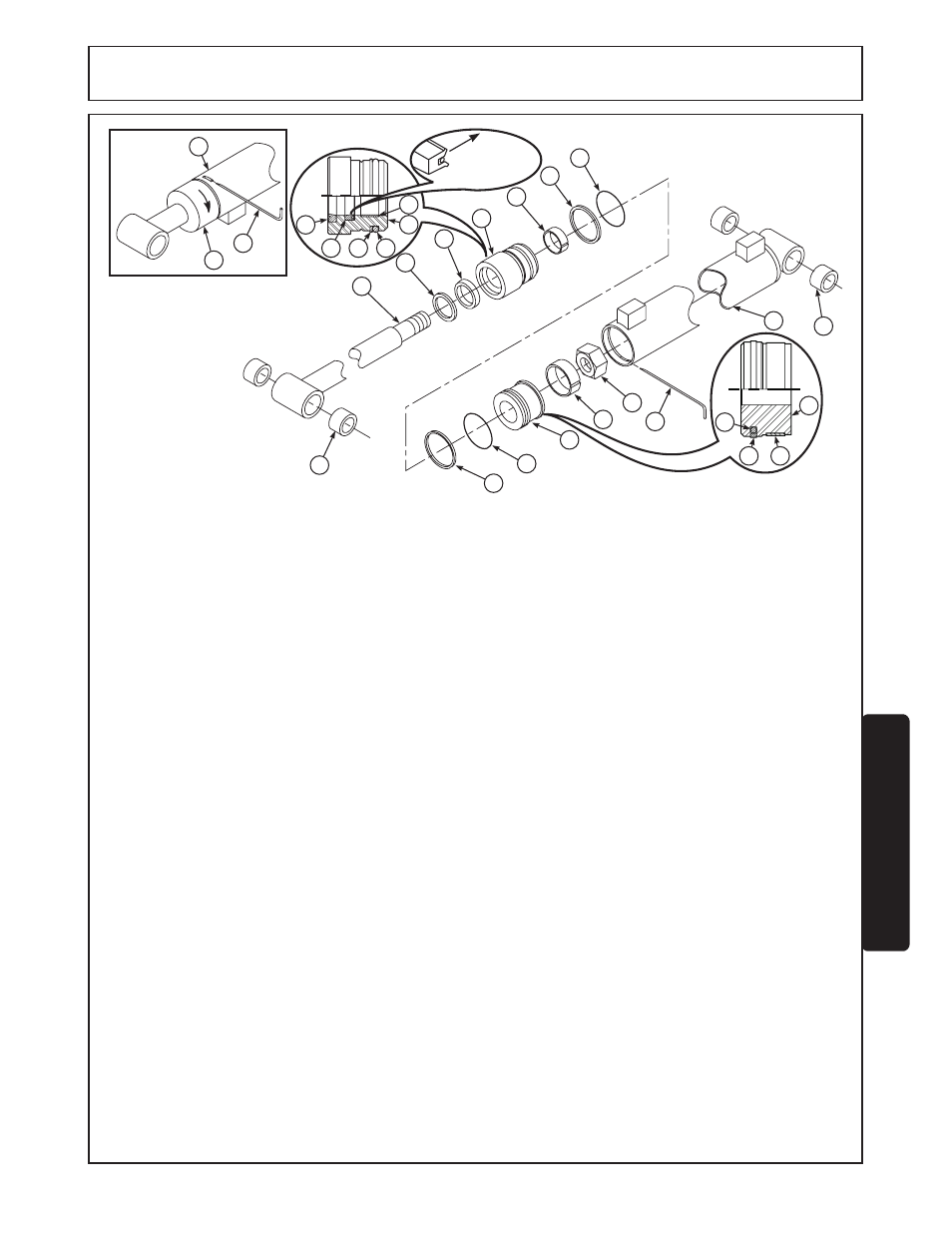

CYLINDER SERVICE

Loader cylinders are designed to be reliable and easy to

service. If a cylinder should malfunction during warranty

period, return complete cylinder assembly, without

disassembling, to your authorized service department or

contact your authorized service department for

instructions. Unauthorized disassembly of a cylinder in

warranty period will VOID WARRANTY.

Following is an outline procedure for disassembling and

reassembling cylinders.

LIFT CYLINDER DISASSEMBLY

1. Remove cylinder from loader.

2. Hold cylinder tube (13) stationary and pull wire ring

(14) out through slot.

3. Pull shaft (1), with all assembled parts, out of cylinder

tube (13).

NOTE: Resistance will be felt until piston seal (8)

slides over wire retaining ring groove.

4. Remove elastic lock nut (12) from end of shaft and

slide cylinder piston (10) and cylinder head (4) off

shaft.

5. Remove piston wear ring (11), piston seal (8), and o-

ring (9) from outside grooves on piston (10).

6. Remove wiper seal (2), rod seal (3), and wear ring (5)

from inside of cylinder head (4) and o-ring (7) with

backup washer (6) from groove on outside of head.

7. Clean all parts, including cylinder tube, in a suitable

cleaning solvent, then use air pressure to blow any dirt

or excess solvent from all parts.

8. Examine all parts for wear or damage and replace, if

necessary.

LIFT CYLINDER REASSEMBLY

NOTE: Be careful not to damage seals and o-rings on

edges or holes in cylinder tube. Inspect and remove burrs

and sharp edges if necessary before reassembly.

1. Place rod seal (3) into groove inside cylinder head (4).

NOTE: Lips of seal (3) must face inward and seal must

be firmly seated in groove.

2. Install wiper seal (2) with lip of seal facing out and flush

with top of cylinder head (4). Install wear ring (5) inside

other end of head (4).

3. Place o-ring (7) with backup washer (6) in groove on

outside of head (4). Backup washer must be to rod

side.

4. Remove sharp edges on outer edge of threaded end of

shaft (1). Lubricate wiper seal (2) and rod seal (3) in

head (4) and carefully slide head (4) onto shaft.

5. Place o-ring (9), piston seal (8), and piston wear ring

(11) in grooves on outside of piston (10).

NOTE: For easier installation, place piston seal (8) in

120°F water to warm seal.

6. Slide piston (10) onto threaded end of shaft and install

elastic lock nut (12). Tighten elastic lock nut to 575

ft.·lbs. torque.

7. Lubricate piston wear ring (11) and piston seal (8) on

piston (10), o-ring (9) on head (4) and inside of cylinder

tube (13), then carefully slide piston and head into

cylinder tube (13).

8. Insert wire retaining ring (14) into slot in cylinder tube

(13). Apply pressure to wire ring to thread it into groove

while turning cylinder head.

© 2004 Alamo Group Inc.

MAINTENANCE

MAINTENANCE

4

14

13

5

5

4

4

6

6

7

7

1

2

2

3

3

11

11

12

14

15

15

13

10

10

9

9

8

8

Lips of seal

(3) must face

inward.

LIFT CYLINDER