13 service the electronics, 14 service the cover, Service the electronics – MagTek EC2000 99875651 User Manual

Page 17: Service the cover, 3 - preventive maintenance procedure

3 - Preventive Maintenance Procedure

ExpressCard 2000| Instant Issuance Card Personalization System | Preventive Maintenance Procedure

Page 17

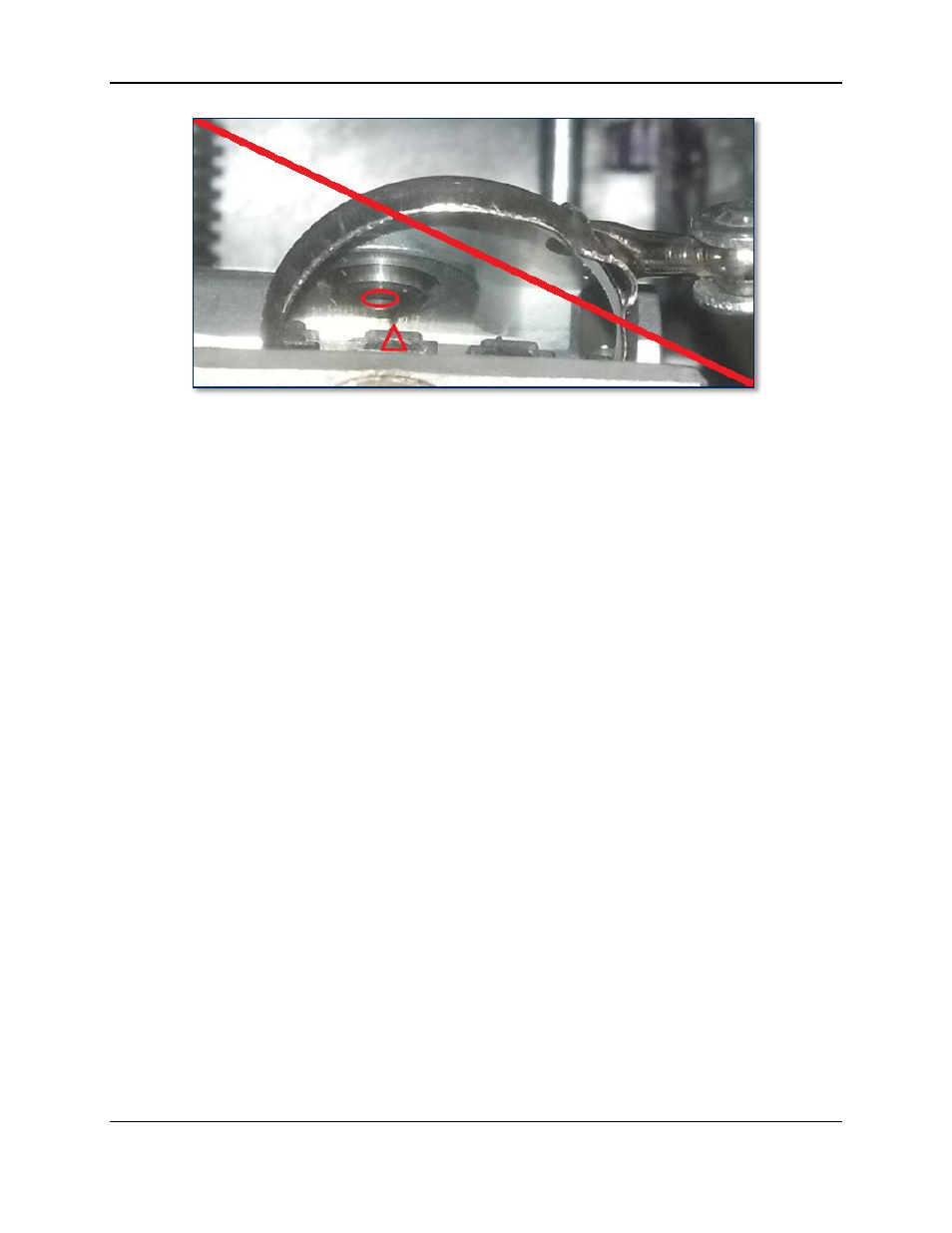

Figure 3-12 - Bad Embosser Wheel Alignment (Figure 3-11 MAGNIFIED)

6) If any cones are broken or bent, replace the characters in the same location if possible. If replacement

is not feasible, cut off the top and bottom tines using the diagonal side cutters, remove the character

from the tines, and install it to another set of tines, and re-map the character to another tine after

preventive maintenance is complete and the device is powered up.

7) Check the daisy wheel alignment by standing in front of the device and looking straight down at the

embosser. Use an inspection mirror as shown in Figure 3-11 so you can see the cone on the bottom

of the current character and the hole in the embosser hammer. Figure 3-12 shows a cone and hole

that are not properly aligned.

8) Check embossed character heights, and adjust them if necessary to account for normal wear. Pay

special attention to any characters you have replaced or re-mapped.

3.13 Service the Electronics

Visually inspect all wires and cables, checking for insulation breakage or wear on moving cables.

3.14 Service the Cover

After completing all other service, service the cover as follows:

1) Inspect the cover for damage.

2) Clean the black and gray portions of the outside of the cover with alcohol wipes.

3) Clean fingerprints off the touchscreen with a soft, clean, dry cloth.