Hydraulic fan system controller: hfs, Software set-up guide – High Country Tek HFS User Manual

Page 21

Hydraulic Fan System Controller: HFS

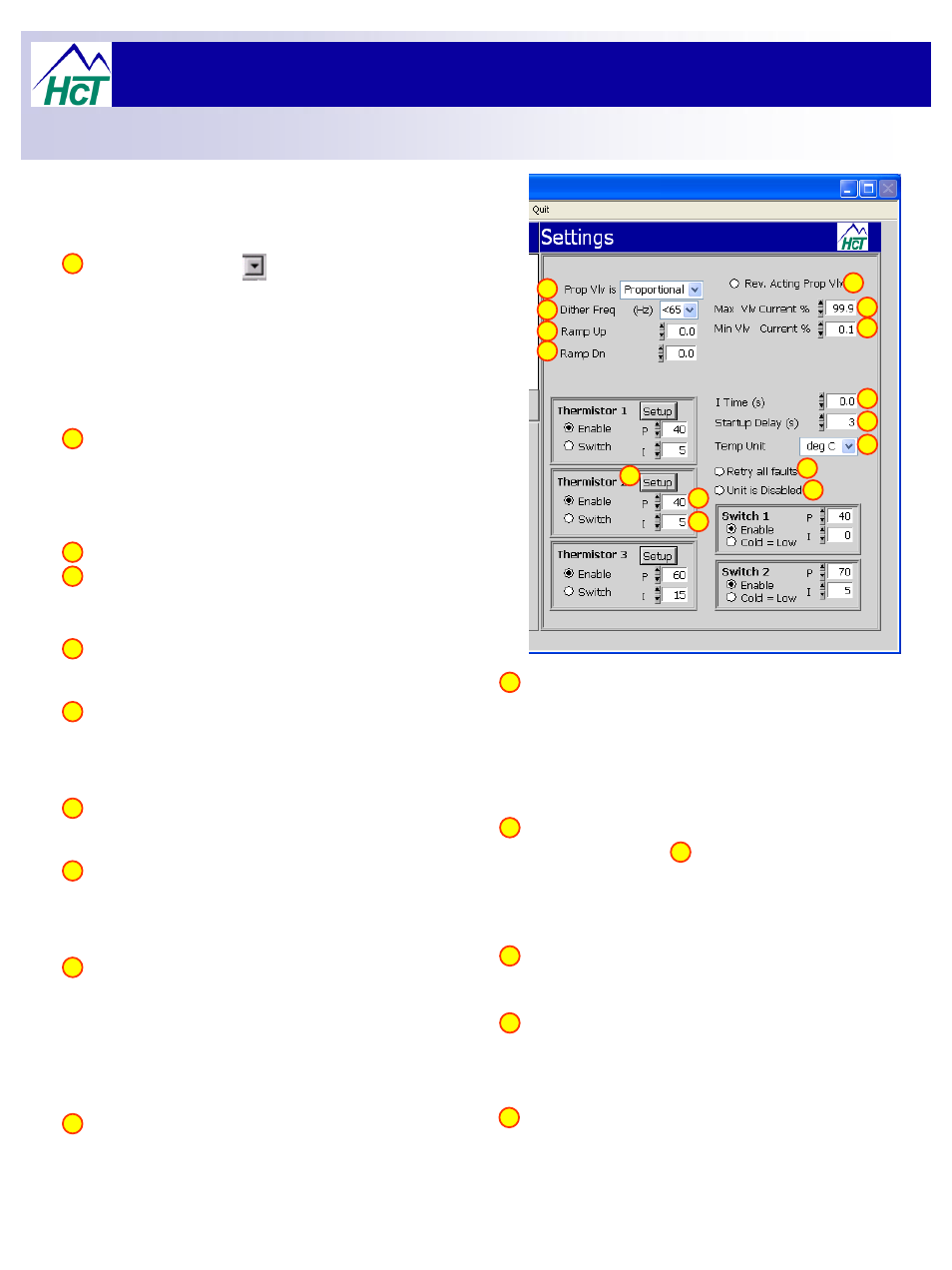

1

2

3

4

5

10

6

7

8

9

11

12

13

1

Click the ‘down arrow ‘ and select from the menu for

‘Proportional or ON/OFF’ type output current. In ON/OFF

mode, no Min, Max, Test or Rev Vlv current settings are

available and the output will be dependent on the supply

voltage to the controller.

In ON/OFF mode the ramps are left active to aide the use

of a ‘soft-shift’ valve if used.

Click the down arrow and select from the drop down menu,

the dither frequency between 31.5Hz and 250Hz that is

nearest to the recommended value for the proportional

valve product being driven.

2

Use the up/down arrows on each box or directly enter a

value ( in seconds ) in the range 0

– 60S for the ramp UP

and DOWN.

3

4

Sets the units of temperature displayed throughout the

software from Degrees Centigrade ( C ) to Degrees

Farenhieght ( F ).

6

Sets the overall ‘Integral’ time constant of the controller.

Update loop

7

This feature is intended to allow vehicle starting with

minimum loading and holds OFF controller action until the

time entered her in seconds ( 0

– 60S ) expires.

8

Click this button to enable ‘retry all faults’ which will allow

the controller to automatically try an error reset every 4

seconds to see if the fault has cleared.

If this feature is disabled, any error will trigger the controller

to shutdown and stop functioning until a ‘Power On Reset’

is applied.

9

Click this button to enable or disable the entire controller.

This button on a new controller is defaulted to disabled.

The first time that a controller is enabled, the date from the

connected PC is ‘Trapped’ and taken as activation date

information.

10

Click this button to allow inverted current output to control

reverse acting proportional valves.

13

Set the Maximum valve current here from 0

– 100%.

Maximum current ( 100% ) depends on coil Ohmic value

and supply voltage and will determine the fans maximum

speed.

This setting must be entered first and the software ensures

that no other settings can be greater than this.

11

Set the Minimum valve current here from 0

– 100% of the

maximum current in. This current will determine the

fans starting speed.

Software ensures that this setting cannot be greater than

the maximum setting.

12

11

See the next page for ‘Thermistor’ set-up details

5

14

15

This is the ‘Proportional’ value that sets how ‘Aggressive’

the change in fan speed is to a change in temperature.

There is a ‘P’ adjustment for each channel

14

This is the ‘Integrator’ value that sets the ‘Accuracy’ of the

change in fan speed to a change in temperature.

There is an individual ‘I’ adjustment for each channel.

15

Software Set-Up Guide:

21