AMETEK 7230 HT Digital Probe User Manual

Page 6

4

1.4 - Installation of a Rigid Probe

The D style connector with dual 3/4 NPT thread does

not require a compression fi tting for installation. The S

style connector will require a compression fi tting, which

is mounted below the tube crimp on the probe to insure

a proper seal.

Assemble the Probe

(See Figure 1.1 on pg. 3)

1. Mount the Compression Fitting (a) if the Style S

connector is being used.

2. Install the bushing if it is used.

3. If the probe has 1 fl oat, (F1), slide the Level Float

(b) or Interface Float (d) onto the probe. If the probe

has 2 fl oats, (F2), slide the Level Float (b) onto the

probe, followed by the Float Spacer (c), and then

the Interface Float (d). The magnet is located in the

middle of the 316 SS Level Float, so orientation

does not matter. The 316SS Interface Float must be

positioned with the plates at the bottom.

4. Slide the Dead Band Spacer (e) onto the probe.

5. Capture these parts with either a retainer E-Clip (f)

or the End Cap (g).

6. Verify that the fl oats and spacers move smoothly up

and down the probe.

Insert the Probe

See Figure 1.2 on page 5

7. Insert the foot of the probe into the tank. Do not

allow the fl oat(s) to drop suddenly since this

could damage the fl oat or retainer at foot of the

probe.

8. Thread the bushing into the tank, fl ange, or bung/

riser. Properly fasten the bushing and fl ange.

9. Thread the compression fi tting or probe into the

bushing or fl ange.

10. Hand tighten. To insure Compression Fitting is

sealed, turn it 1 1/4 turns after hand tightening.

11. Make fi nal check to see that all fasteners are

in proper position and that the probe is securely

tightened.

1.2 - Mounting Conditions

1. The 7230 Series HT Digital Probe level system

is designed for industrial applications, but should

be mounted in a location as free as possible from

vibration, corrosive atmospheres, or any possibility

of mechanical damage.

2. Mount the probe in a reasonably accessible location,

away from agitation.

3. Process temperature is between -40°F and 257°F

(-40°C to 125°C).

4. Mount the probe perpendicular with gravity so the

fl oat moves freely along the probe.

CAUTION

When installing probes, do not bend rigid

probes. Permanent damage may result.

(Consult factory about a telescoping

support to assist with the installation of

20-24 ft. probes) Rigid probes, longer than

10 ft., need to be supported at both ends

while handling. Remove the Caution Tag

before installing. Probes are built with the

electronic circuits sealed inside the tube at

the factory. Do not attempt to open or weld

on the tube.

1.3 - Unpacking

Carefully remove the contents of the shipping carton

and check each item against the packing list before

destroying the packing materials. Any damage must be

reported to the shipping company. If you do not receive

all of the parts on the packing slip, contact Ametek

at 800-635-0289 (US and Canada) or 248-435-0700

(International).

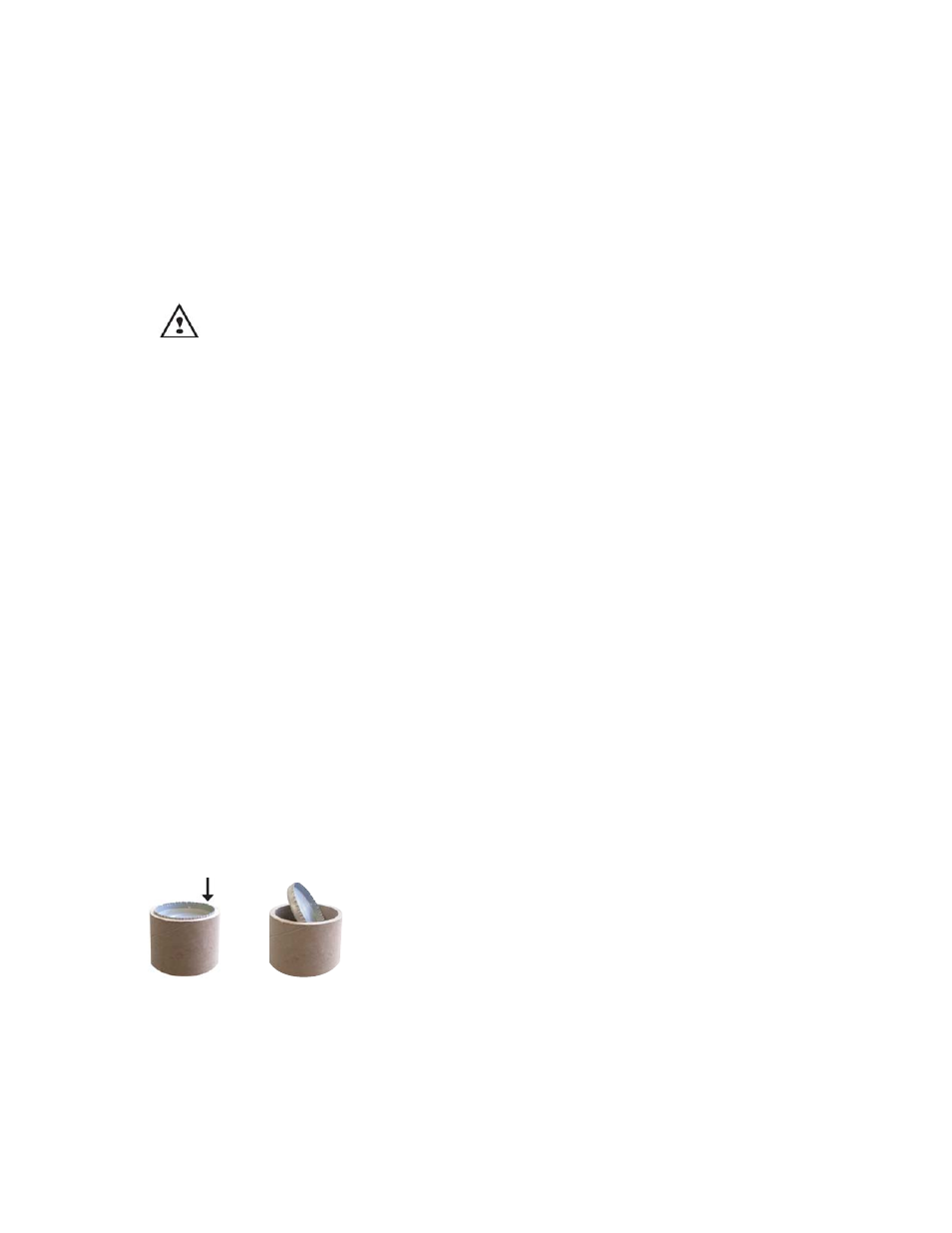

Most rigid probes are shipped in a Tube. To remove the

metal end cap, use a large, fl at blade screw driver or a

metal rod and tap on the inner edge of the cap until it

pivots. Grab the cap and pull it out. Use caution as the

edge of the metal cap may be sharp.

If you have an RMA warranty claim, pack the probe in a

shipping tube or with stiff reinforcement to prevent the

probe from being bent in transit.